Analysts and science fiction writers alike have been talking about it forever, and finally, the future seems to be at our doorstep: The era of electric vehicles, cars that drive themselves, and machines that build machines. But what about the factory floor? Is the automotive factory floor of the future here too?

The automotive factory of the future ideally behaves less like fixed hardware and more like updatable firmware — one that can incorporate new models, new methods, and new workflows with minimal physical rework. It involves integrating virtual simulations, intelligent automation, optimized use of sensors and AI, and on-demand manufacturing technologies for less downtime, and greater impact.

Adaptive and Forward-Thinking: Reimagining Layouts with Simulation & Virtual Twins

The foundation of a future-proof automotive factory starts with adaptive layouts that anticipate change rather than react to it. Virtual twins — virtual replicas of physical environments — enable you to simulate and optimize factory floors in real-time, identifying bottlenecks before they disrupt production.

With simulated environments, you can see exactly what works before you move a single machine. And it can be as simple as using 3D models for small shop layouts or as big as simulating your entire factory floor. But a true virtual twin isn’t simply a pretty 3D model — it’s an always-on, real-time replica fed by thousands of sensors and controls.

Virtual Twins with DELMIA Factory Simulation: Simulate robots, humans, AMRs (autonomous mobile robots), energy flows, and live data (integrated with SOLIDWORKS); drag-and-drop assets to test cell layouts, lights-out runs, and “what-if” scenarios like congestion or energy use.

In automotive, more people crave customization, and on top of that, the quantity and types of components have increased with the proliferation of EVs. Automotive suppliers face challenges with faster and faster product changes and more frequent line re-configurations.

Factory sim can help them stay ahead of this by simulating high-mix/low-volume lines to minimize changeover time and identify bottlenecks.

Actionable Tip

Start with one virtual twin of your highest-mix line (not the whole plant). It has the most variants and the most changeovers, and thus, the highest ROI when optimized.

Turning the Factory into Firmware: Automating the Monotonous and Potentially Perilous

Automation is the main way you get the efficiency and consistency needed to meet car manufacturers’ tough demands for quality, speed, and cost — by boosting production volume and making everything more precise.

Transforming rigid assembly lines into programmable “firmware” means offloading repetitive and hazardous tasks to automation, freeing human workers for higher-value activities. This can mean anything from adding the integration you know you’ve needed for several months to adding cobots to the factory floor.

It might not seem like much, but BMW saved more than 8 hours in unplanned downtime annually just from their use of cobot sensors. Every minute or hour recouped adds up to big efficiency gains in the long run.

Some companies are even able to add their own moonlighting shift with cobots, boosting machine utilization by 40% and doubling part output for true lights-out manufacturing.

And manufacturers taking advantage of DELMIA Factory Automation and Robotics can further automate the factory floor with offline programing and simulation to optimize robot workcells, decreasing downtime and optimizing the factory floor.

Read more about DELMIA Robot Programming:

- On-Demand Webinar: Automate Your Machine Tools with DELMIA Robot Programmer

- Downloadable PDF: 3D Robot Programming Reduces Costs and Streamlines Production

Actionable Tip

Put one cobot on your ergonomically worst job or add an overnight shift. Recover worker time for value-added tasks.

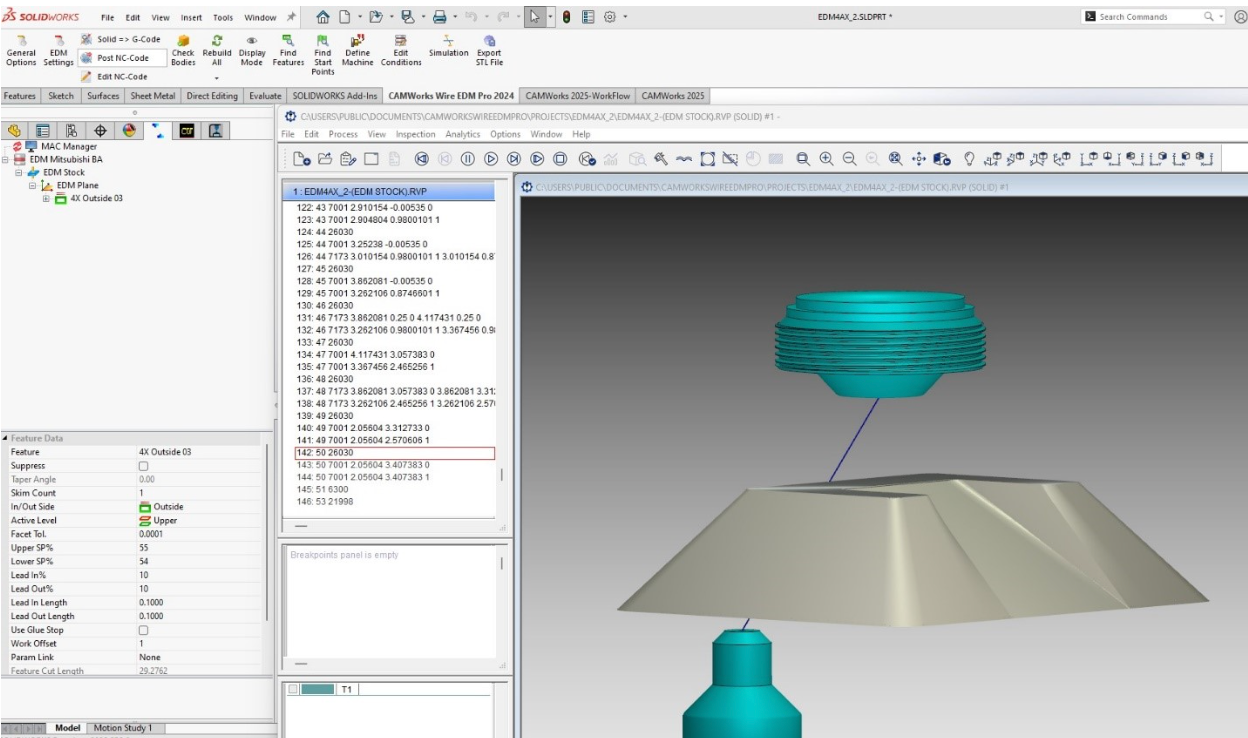

Not ready for cobots? Integrating CAD and CAM can boost shop floor efficiency too. With this integration you can streamline machining processes, increase machine utilization, and cut errors and setup time across operators.

Speedway Motorsports increased production by 300% with their CAM and CAD integration.

Trading Horsepower for Compute Power: Additive Manufacturing to Eliminate Downtime

Waiting four weeks and paying thousands of dollars for a machined fixture is no longer acceptable when you can just do it yourself and have it today. One of the quickest ways to “future-proof” your factory floor is to bring in additive. Spit out tooling, jigs, and fixtures same day with Markforged FX10 or Metal X. Get the part you need in hours for less.

Leading suppliers now keep zero inventory of low-volume jigs, gauges, and robot EOAT (end of arm tooling). They design in SOLIDWORKS in the afternoon, validate strength with Simulation, and print before the next shift. Downtime caused by “no fixture available” has become a relic of the past for many shops.

Actionable Tip

Bring 3D printing in-house for immediate ROI. Start small: Replace one broken fixture or missing tool per month using the Markforged FX10 or Metal X.

Looking to go beyond just simply adding 3D printers? A combination of Markforged 3D printers for tooling, SOLIDWORKS Design, SOLIDWORKS Simulation for validation, and SOLIDWORKS PDM for version control allows suppliers and aftermarket shops to design, validate, and print production-ready tooling overnight, keeping lines running without interruption.

Partnering for the Road Ahead

Futureproofing isn’t just about adopting individual technologies — it’s about integrating them into a cohesive, scalable system, one that’s intentional, not haphazard.

The factories that will still be profitable ten years from now have already started this journey. They treat physical assets as configurable code and leverage key integrations to maximize their setup and throughput.

And they have partners like Hawk Ridge Systems walking the floor with them — turning SOLIDWORKS, Markforged printers, and CAMWorks into the central nervous system of a truly future-proof operation.

Hawk Ridge Systems is the trusted partner guiding suppliers and aftermarket companies through this transformation, implementing and training employees on tools like DELMIA Factory Simulation to create accurate virtual twins that integrate directly with factory simulations and production planning.

From Tier-1 suppliers to high-performance aftermarket manufacturers, Hawk Ridge Systems helps companies build resilient, compute-driven factories ready for electrification, autonomy, and everything that comes next.