Free CAM Post Processors

Standard and Custom Post Processors for CNC Programmers

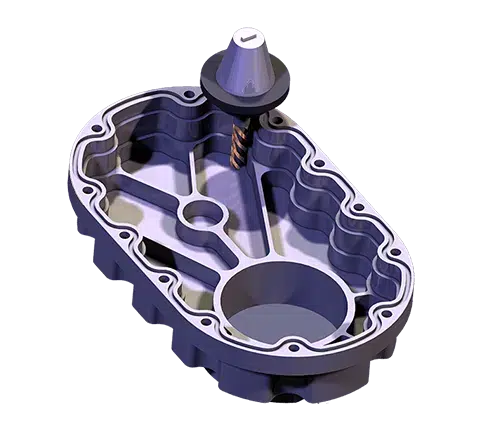

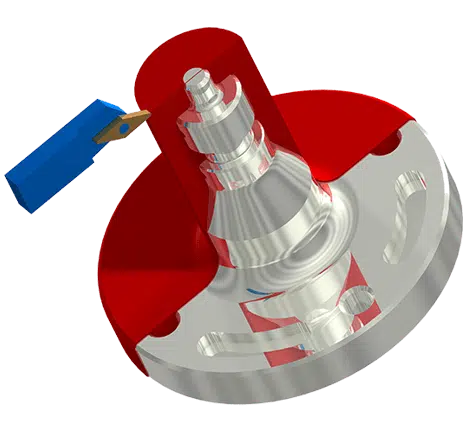

In a CAM system, CNC machine movements are visually represented on-screen using lines, arcs, circles, and splines, with each displayed tool path corresponding to a Cutter Location (CL) value. Behind the scenes, post processors convert this CL data into machine-specific G-code required for proper operation.

Choosing the right post processor is crucial, as it ensures the accurate translation from the virtual image to G-code, preventing potential machine crashes. The post processor acts as a behind-the-scenes guide, facilitating a seamless transition from the digital representation to the physical manufacturing process.

How Hawk Ridge Systems Can Help?

Over the years, we have produced exacting code for clients of all sizes and the most demanding machines. We have a full-time dedicated staff that writes and handles post processors only, leveraging their combined 75+ years of experience. This allows for fast turnaround times and more individual focus on your immediate need.

- When an aerospace company with over 125 CNC machines, some costing as much as $2 million, needed a company they could trust for post processors they turned to us.

- When a tier 1 automotive supplier needed parts fast for a new machine, we provided the post processor within days.

- It’s not all about the big companies – we are here for you no matter how large or small. We were just as happy to supply a small shop with their Röders ultra-high-speed milling machine post processor.

Frequently Asked Questions

Services & Customer Benefits

Technical Support

Unmatched Training

We’re one of the largest engineering training providers in the world, offering both online and on-demand training so your team knows how to get the most out of your tools.

Professional Services

With 75+ years of combined experience, the Hawk Ridge post writing team specializes in crafting post processors. We’ll work closely with your company to provide the right one for your specific machine.