AMT PostPro

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

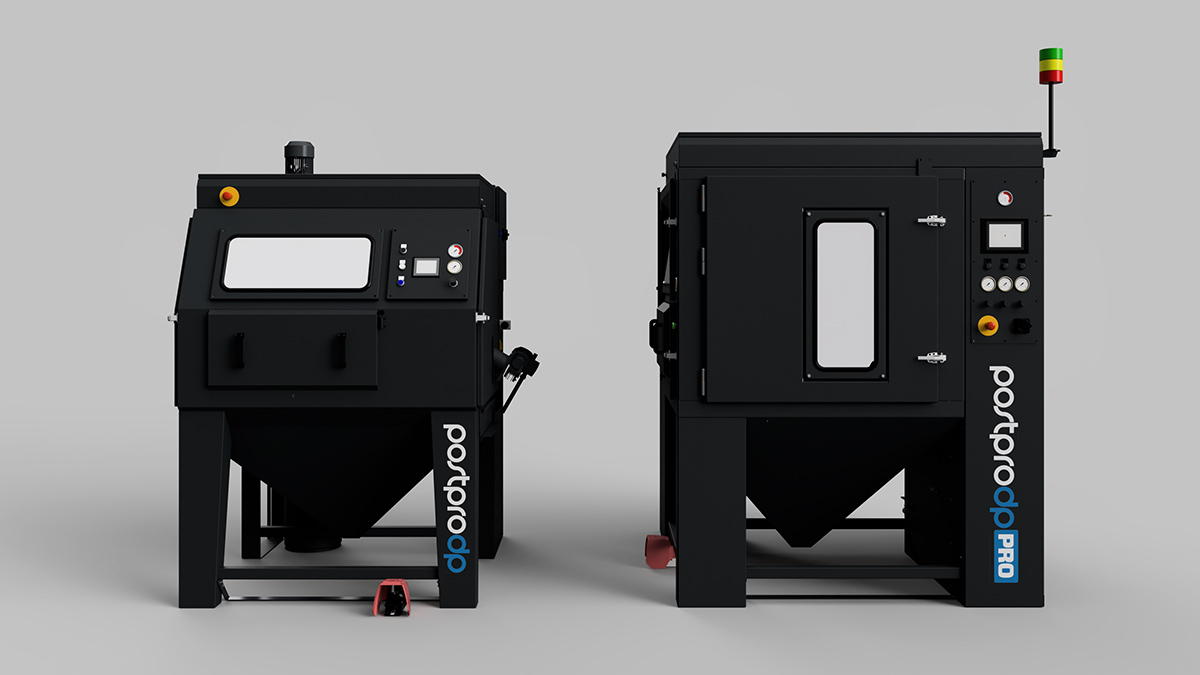

AMT Vapor Smoothing Systems

AMT PostPro SF100 and PostPro SF50 industrial vapor smoothing machines process 3D printed parts, giving them the look and feel of injection molded parts.

AMT Depowdering Systems

AMT depowdering systems are designed to significantly reduce your post-processing time and labor with automated bead blasting to clean 3D printed parts of all sizes.

Exceptional Solutions, Even Better Support

Creating the best products requires the best solutions, training, and support. With a little insight into your product development process, our team of pros can point you to any tools you need (and nothing you don’t).

But it doesn’t end there. We’ll stay with you every step of the way, helping solve complex design issues, 3D printing application questions, and so much more. No matter where you’re at, both in your process and geographically, we’re here.

Post-Processing Resources

Give Your Printed Part the Finished Look It Deserves

Watch Webinar

Design, Print, Ride – A Product Journey

Watch Webinar

3D Printer Buyer’s Guide

Download GuideFrequently Asked Questions

Yes, reach out to the team at Hawk Ridge to receive an AMT PostPro benchmark sample.

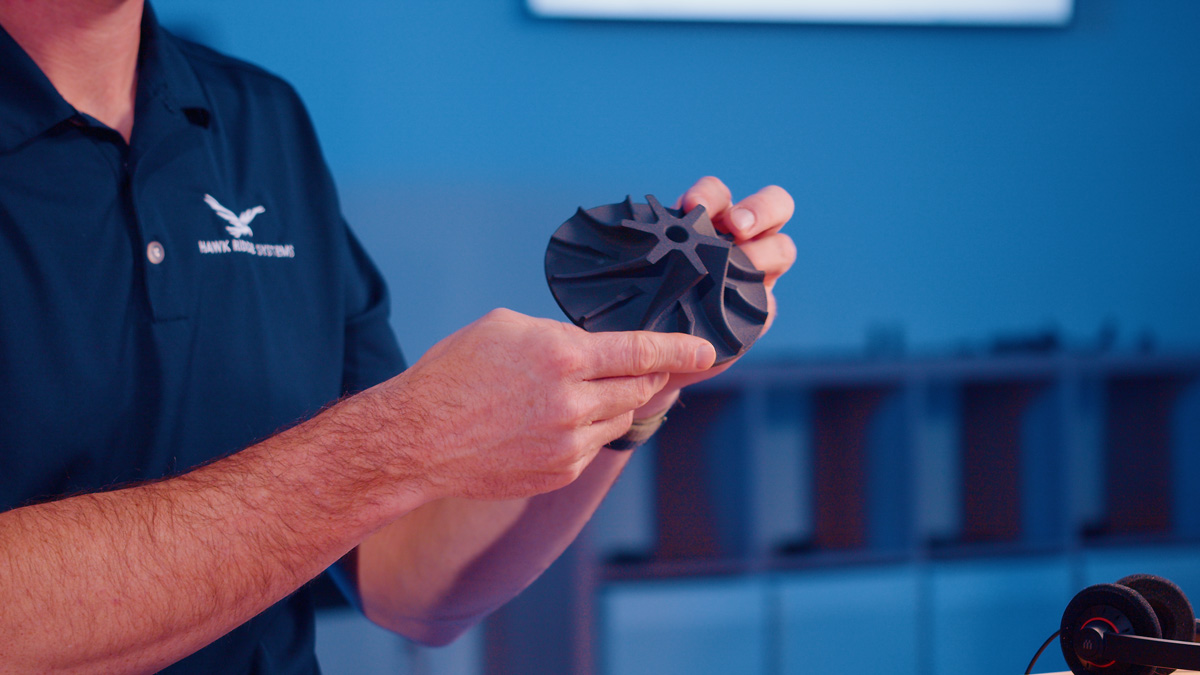

Parts from powder-based systems like HP Multi-Jet Fusion and parts from FDM systems tend to show the most improvement from the vapor smoothing process. HP parts even have a color improvement from gray to black after undergoing vapor smoothing.

HP Multi-Jet Fusion and SLS technologies lend themselves well to automated bead blasting equipment from AMT.

It all depends on how many parts you are producing and what sizes and shapes of parts you consistently run. If you are planning on running high volumes of parts, then an AMT bead blasting machine is a no brainer because of how much time it saves and how consistent the final product is. Reach out to the Hawk Ridge team to run an analysis for your specific part geometries.

Services & Customer Benefits

Technical Support

Our dedicated team is here to provide comprehensive support, including thorough pre-installation planning and expert installation services. By leveraging our expertise, we ensure a seamless process to swiftly set up your AMT system, allowing you to get up and running with ease.