Markforged FX10 3D Printer

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

For Scaling Strong Parts, Printed Right Every Time

The FX10 offers unparalleled functionality and efficiency for industrial 3D printing needs. It prints with precision at a remarkable max print speed, allowing manufacturers to scale, increase speed to market, de-risk downtime and reduce fabrication and inventory costs.

Blending powerful automation with brilliant ingenuity, the FX10 has dual print head optical sensors that use a new Vision Module to capture detailed images of calibration parts and a laser micrometer to validate in-print dimensions and power machine calibration. It produces accurate, continuous carbon fiber reinforced parts — meeting the most stringent requirements on the factory floor.

Leveraging Markforged’s additive platform, Digital Forge, the FX10 has intuitive features that let you build your ROI from the get-go.

Key Features & Benefits

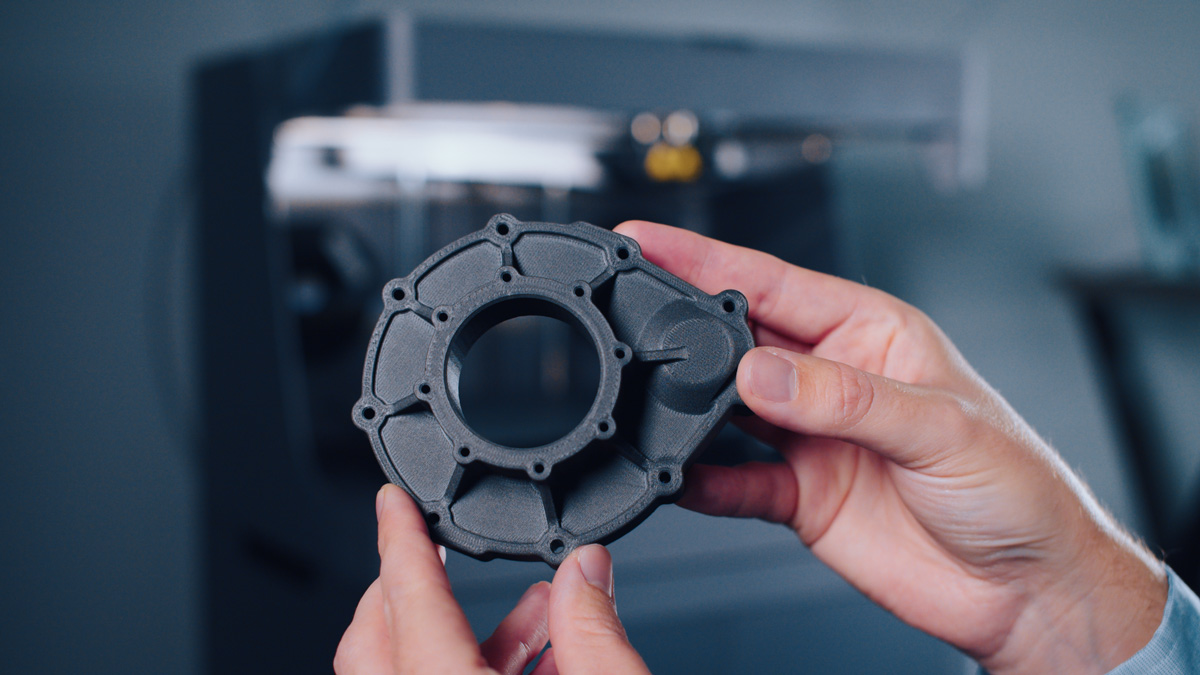

Onyx and Carbon Fiber

Whether you’re creating prototypes, functional parts, or intricate designs, Onyx and Carbon Fiber deliver unmatched quality and durability.

Heated Build Chamber

Advanced Material Chamber

Increased Max Print Speed

Eiger Software

Eiger is a cloud-based slicing software for sending and managing print jobs for all Markforged printing systems. It’s free to use. Sign up and try it today!

Simulation & Inspection Software

Laser Automated Bed Leveling

Vision Module for Detailed Calibration Imaging

Technical Specifications

|

Features

|

FX10

|

|---|---|

|

Build Volume

|

375 x 300 x 300 mm (14.8 x 11.8 x 11.8 in)

|

|

Layer Thickness

|

125μm minimum, 250μm maximum

|

|

Machine Size

|

760 x 640 x 1,200 mm (30 x 25 x 46 in)

|

|

Machine Weight

|

109 kg (240 lbs.)

|

|

Power Requirements

|

100-120 VAC 12A / 15A or 200-240 VAC 6A / 8A

|

Revolutionizing Dragsters With Markforged

In the high-speed, high-stakes world of jet engine drag racing, manufacturing quality parts is a matter of life and death. Just ask Josette Roach, one of only five female jet dragster drivers in the entire world.

Josette Roach and Brian Tocci of Larsen Motorsports saw the need to create a custom steering wheel for Josette’s jet car that would fit her hands exactly. Enter Markforged, and our Simulation software, which allowed the team at Larsen to build this part with top-end accuracy.

Markforged Resources

Which Is the Best Markforged 3D Printer for Your Business?

Read Article

Supercharge Your Manufacturing with the Markforged FX10

Download Guide

Announcing the New Markforged FX10 Industrial 3D

Read Article

5 Revolutionary Markforged FX10 Capabilities

Read ArticleFrequently Asked Questions

When it comes to fused filament fabrication (FFF) printers, many factors — like the micron setting, complexity of the print job and the printer’s capabilities — determine print speed.

Generally speaking, the FX10, set at a 250-micron turbo mode, prints about twice as fast as the X7 at a higher print quality and matches the print speed of the FX20 turbo mode. As far as the smaller desktop printers like the Mark Two, it prints eight times faster at the lowest 100-micron setting and four times faster at the highest 200-micron setting.

Onyx and carbon fiber materials are available right now for the FX10. There will be more materials added later.

No. While the FX10 has two powerful sensors in the print head, these automations enhance the printing experience.

For example, the FX10’s precision micrometer point laser scans the print bed and calibrates the machine when changes and micro abnormalities happen, which allows you to get perfect parts every time. And its built-in automation in the material storage chamber will reload spools when the active spool is exhausted.

Services & Customer Benefits

Technical Support

Unmatched Training

Hawk Ridge offers complete self-paced training programs for the Markforged line of 3D printers. Learn printer operations, how-tos, and best practices when it’s convenient for you.