Eureka

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

Increase CNC Machine Productivity and Avoid Collisions

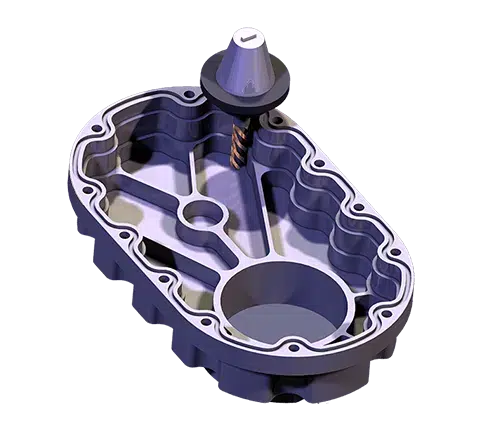

Eureka software offers a digital replica of workshop machines on your computer, allowing quick testing without disrupting production or risking damage to workpieces and tools due to programming errors.

Eureka G-Code is a top NC simulation software for any CNC machine, accurately simulating G-code regardless of its origin. It utilizes a precise “digital twin” of the machine tool and CNC controller for thorough program preparation and verification.

Eureka Robot combines a 6-axis robot’s flexibility with CNC machine center technology, converting CAM-generated APT code into a program for robot cells. It calculates optimal movements and simulates machining processes for comprehensive planning.

-

Multi-Channel Machine Simulation

Eureka supports machine tools driven by multiple NC programs for one job.

-

Eureka Viewer

The Eureka Viewer Module will allow you to save Eureka simulations to a file. You can download Eureka Viewer for free and play saved simulations on computers without Eureka installed, or on mobile devices.

-

Probing Module

The Eureka Probing Module will emulate probing cycles, including motion stops when the probe touches objects or calculates work offsets.

-

Machine Configuration Editor

This module can create or edit any machine configuration and kinematics within your purchased machine tool or robot license level. You have access to a full machine controller library including standard macros.

Exceptional Solutions, Even Better Support

Creating the best products requires the best solutions, training, and support. With a little insight into your product development process, our team of pros can point you to any tools you need (and nothing you don’t).

But it doesn’t end there. We’ll stay with you every step of the way, helping solve complex design issues, 3D printing application questions, and so much more. No matter where you’re at, both in your process and geographically, we’re here.

Manufacturing Resources

Are Your CAM Tools Working Together? They Should Be.

Watch Webinar

Introduction to SOLIDWORKS CAM

Watch Video

Alien Machine Worx Success With SOLIDWORKS

Watch Video

3 Strategies to Master for Future Manufacturing Success

Download GuideFrequently Asked Questions

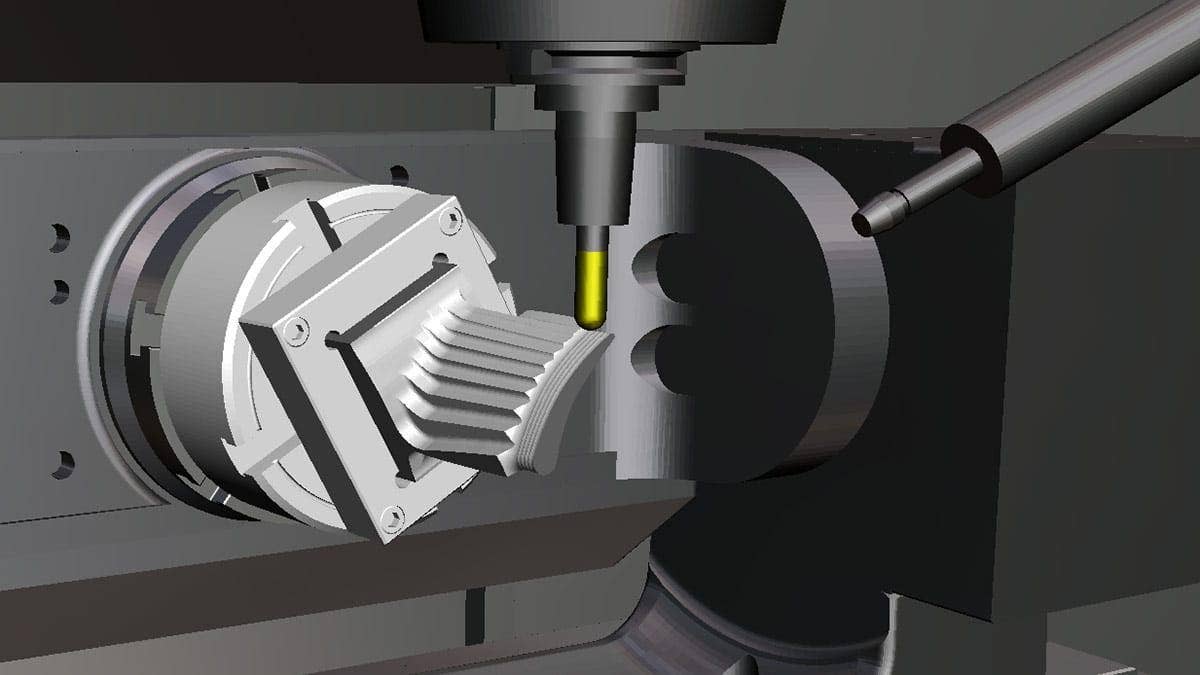

CNC machines are complex and expensive. Four and five axis mills and live tool lathes have lots of components moving rapidly in a small space. Simulation can catch programming errors before they cause damage to your tooling and machine. Not only does this help with crash prevention, but it means that the machine can keep cutting parts while you perform your tests.

Yes. The simulator will read the code, interpret the commands, and simulate the movements.

You don’t! Once your part is programmed in CAMWorks, simply choose the Machine simulation option from the right click menu and your simulation will be setup for you. The stock, parts, fixtures, tooling, program and offsets are passed directly to Eureka and you just need to click play.

Unlike a lot of other machine simulators, Eureka reads directly off the G-code, so you can hand-write code, or use your CAM system’s post processor. Other simulators often require an APT post processor that will first translate your program to APT language, simulate the APT language, and then post process again to produce the G-code. Eureka does offer a cost-effective option that simulates from APT code and the CAMWorks APT post processor is supplied with the simulator.

Yes. Eureka Robot converts APT code generated by a CAM system into a program for a 6 or more axes robot cell using a dedicated postprocessing module. During the conversion process, Eureka calculates the optimal movements of the robots and of the external axes simulating all aspects of the machining. The software detects problems like singularities, collisions, and out of limits, offering powerful, easy-to-use tools to overcome them. Collisions are computed taking into account all the parts, including the machined stock. Eureka Robot supports any number of external axes (rotary tables, linear rails, etc.), automatic tool changes, multiple spindles, shared motors, fixed tools, and robot-mounted parts.

A wide range of controllers are supported including Fanuc, Haas, Siemens, Heidenhain, Okuma, Mazak, Mitsubishi, Osai, Allen Bradley, and Fagor among others.

Services & Customer Benefits

Technical Support

Our global support team efficiently addresses your needs. We’re here to minimize downtime and costs when your machines encounter issues. If we supply a post processor, expect ongoing support and updates throughout your contract.

Unmatched Training

Our Certified CAM trainers draw from extensive software and real-world machining experience for your productivity. Choose from various training options, including self-paced, instructor-led, and private, tailored to your needs and learning style.

Professional Services

We offer comprehensive CAM and CNC machining software services, including swift implementation, free or customized post processors for seamless software-machine integration, and personalized consulting for ongoing productivity.