Predator Software

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

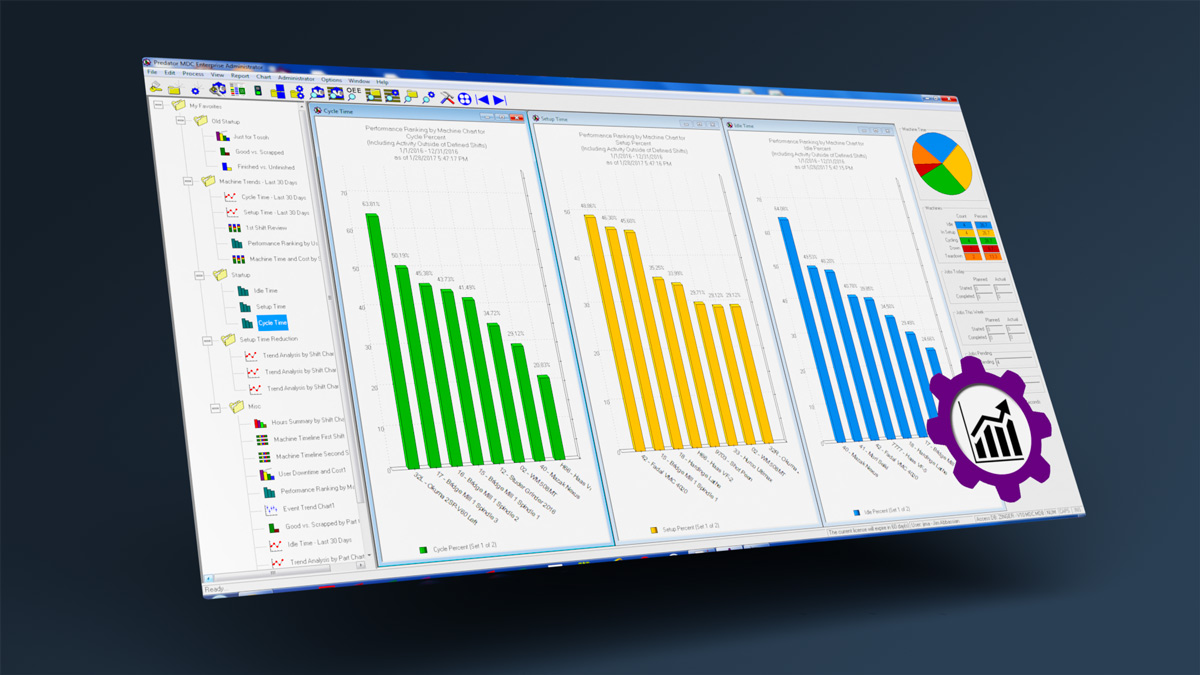

Predator MDC

Predator MDC allows you to monitor your shop floor and collect real-time manufacturing data, including what is running, how many parts have been made, machine idle time, and much more.

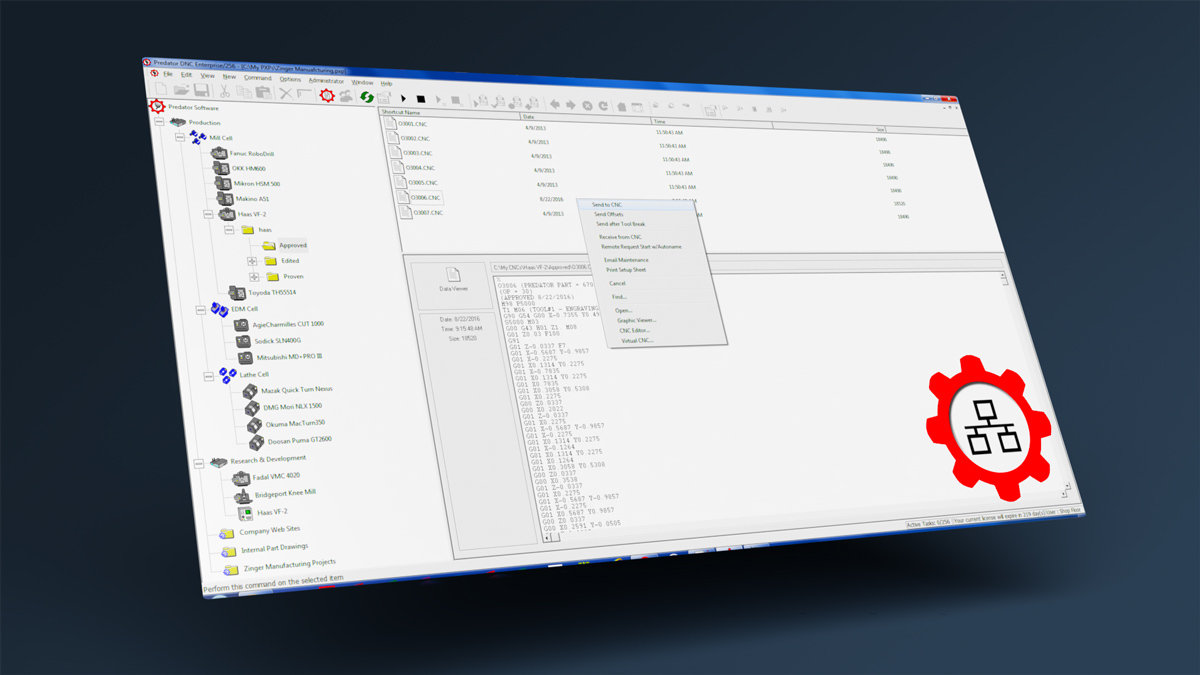

Predator DNC

Predator DNC helps you manage your files, letting you effortlessly send and receive files to and from your CNC machines, either automatically or with a few short clicks, depending on the machines.

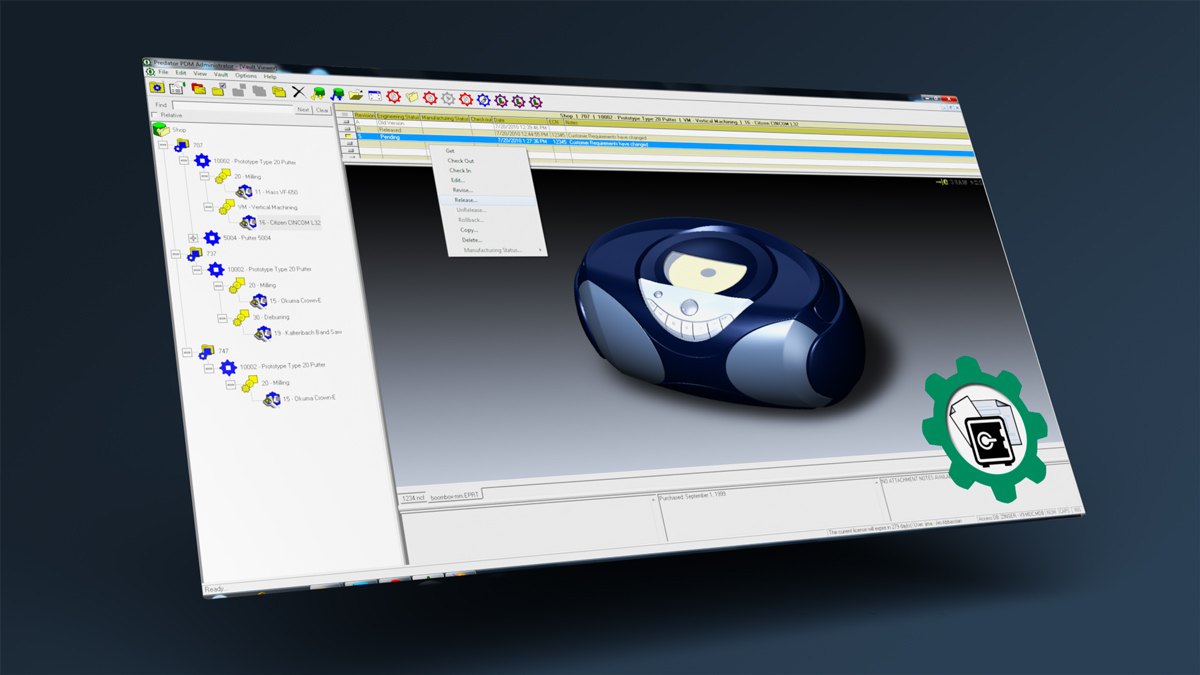

Predator PDM

Predator PDM (Product Data Management) software allows you to create a paperless manufacturing environment with built-in revision control and workflow optimization.

Exceptional Solutions, Even Better Support

Creating the best products requires the best solutions, training, and support. With a little insight into your product development process, our team of pros can point you to any tools you need (and nothing you don’t).

But it doesn’t end there. We’ll stay with you every step of the way, helping solve complex design issues, 3D printing application questions, and so much more. No matter where you’re at, both in your process and geographically, we’re here.

Manufacturing Resources

Are Your CAM Tools Working Together? They Should Be.

Watch Webinar

Introduction to SOLIDWORKS CAM

Watch Video

Alien Machine Worx Success With SOLIDWORKS

Watch Video

3 Strategies to Master for Future Manufacturing Success

Download GuideFrequently Asked Questions

Yes, Predator DNC allows for running long programs that do not fit into your control seamlessly.

Yes, they can. Optionally, the full suite of Predator products can be seamlessly integrated to leverage multiple tasks and improve productivity. For example, you can use Predator PDM to send programs to the CNC through Predator DNC.

Yes. Predator software can communicate with old equipment, as well as the latest machine innovations.

Predators MDC can collect data in a number of ways. From old school electronics signals to d-print statements, to the latest in MT-Connect enhancements, Predator MDC can interface with them all.

Services & Customer Benefits

Technical Support

Our manufacturing support team has substantial experience with Predator software and installations, and we pride ourselves on making sure you and your solutions remain active and productive.

Professional Services

Our dedicated manufacturing services team has extensive experience and provides complete installation services, including one-on-one training, to get you up and running quickly.

Unmatched Training

Our trainers draw from extensive real-world machining experience for your productivity. Choose from various training options, including self-paced, instructor-led, and private, tailored to your needs and learning style.