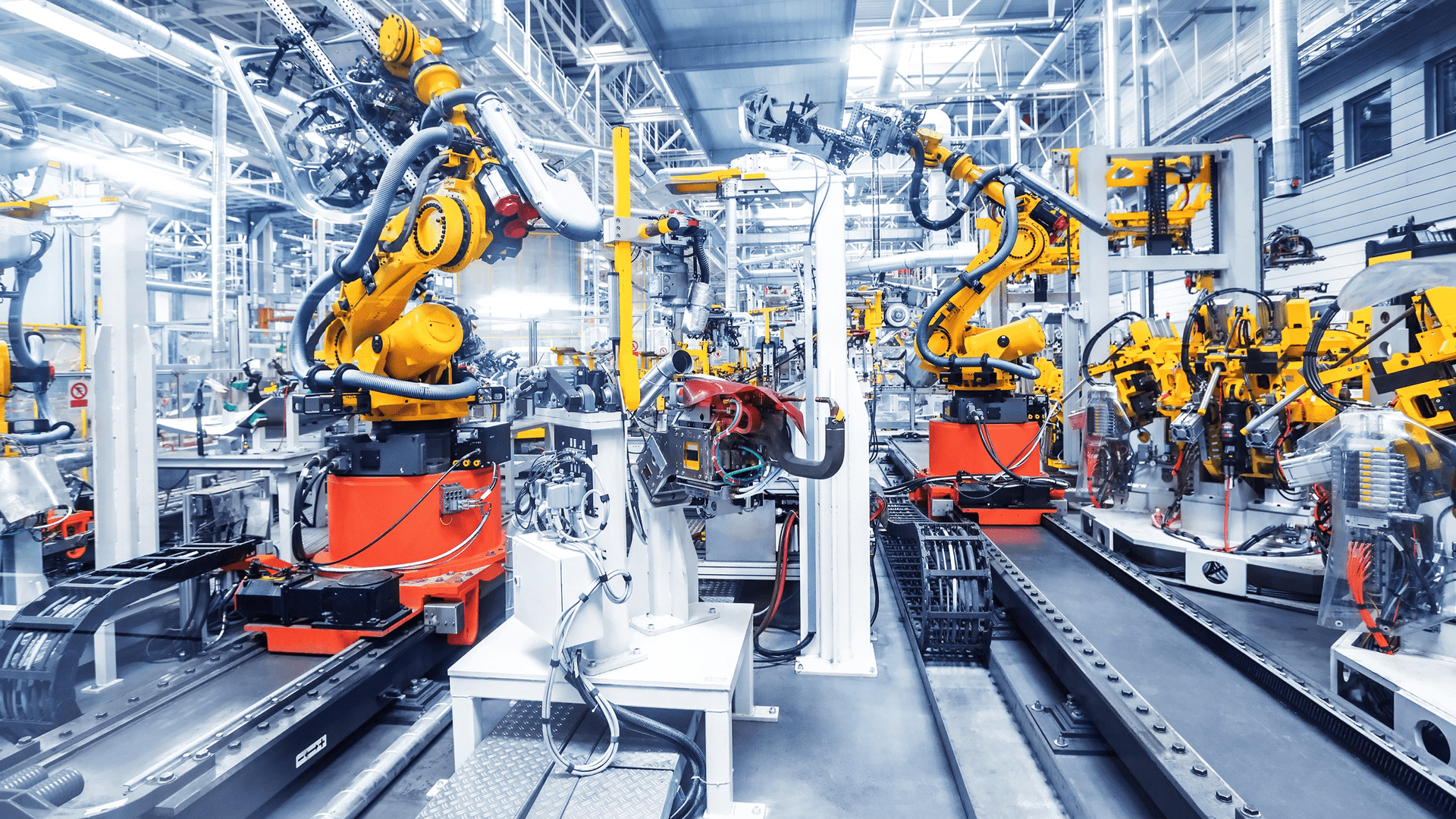

3DEXPERIENCE DELMIA Factory Automation & Robotics

Create, simulate, and optimize programs for the entire robot workcell and robot trajectories offline in a collaborative environment, the 3DEXPERIENCE platform.

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

Program Offline, Keep Your Robots Online

DELMIA robotics software validates production systems and robot programming within a 3D collaborative environment. Workcell programmers can program, simulate, and deliver high-quality, collision-free programs in the native robot language with minimal disruption to production, allowing manufacturers to ramp up their systems with confidence the robots will perform as expected.

-

Comprehensive Robot Programming

Benefit from comprehensive programming functionalities, including:

- An intuitive, robot teach pendant-like user experience.

- The ability to add kinematics for end effectors, clamps, and fixtures.

- Support for advanced logic, as well as input and output in device programs.

- Compatibility with pick and place, arc welding, adhesives, cutting, & machine tending.

-

Accurate Process Cycle Time Analysis

Validate all designs, processes, and resources to mitigate issues that cause rework, reduce workcell build errors, and calculate optimal robot placement — all while validating the robot and workcell cycle time before the cell is even built.

-

Extensive library of pre-configured Robots

Leverage 1,400-plus pre-configured robots from manufacturers, including: ABB, ACMA, Adept, Arcman, Cloos, Comau, Daihen, Denso, Doosan, Duerr, Epson, Fanuc, Hyundai, IGM, Kawasaki, Kuka, Mitsubishi, Motoman, Nachi, Omron, Panasonic, Reis, Staubli, Universal, and Yamaha.

-

Offline Robot Programming in Native Robot Language

Streamline collaboration between robot programmers and product or tool designers with offline programming, allowing the robot to stay in production while being re-programmed virtually.

Bi-directional translators include: Staubli, Universal, Kobelco, ABB, Nachi, Fanuc, Daihen, Yaskawa, Denso, Kuka, Panasonic, Kawasaki, Epson, and Durr.

-

Calibrate the Robot Workcell

Arrange the virtual model precisely as the real workcell to connect the dots between the virtual and real workcell. Calibrate the robot precisely by calculating the robot signature and have a seamless upload and download of robot programs between the virtual and real robots.

-

Validate throughput of the Workcell

Spawn parts into the cell to validate throughput and test PLC logic. Source and sink capabilities provide multi-cycle simulation of product flow through the cell:

- A source introduces the product representations to be processed in the system.

- A sink eliminates the processed products or transforms them into the next process iteration of the product.

-

Sensor Modeling and Behavior (Beam, Plane, & Volume)

Create and manage virtual sensors to:

- Get real-world communication of events in the virtual

workcell. - Validate sensor placement.

- Realize the true operating cycle of workcell machines.

- Get real-world communication of events in the virtual

Maximize Manufacturing Efficiency, Quality, and Productivity With 3DEXPERIENCE DELMIA

3DEXPERIENCE DELMIA manufacturing solutions offer an integrated approach to managing your entire manufacturing lifecycle, from initial design to final production. Being connected to the cloud-based 3DEXPERIENCE platform enables seamless collaboration between teams and stakeholders, eliminating disjointed workflows to maximize productivity.

Watch this video to learn more about 3DEXPERIENCE DELMIA solutions.

Services & Customer Benefits

Technical Support

Our support team is always ready to answer 3DEXPERIENCE questions and assist with troubleshooting. Want to dig a little deeper? We can work through your tougher challenges in a dedicated Ask-an-Expert session.

Unmatched Training

Hawk Ridge Systems, a global 3DEXPERIENCE leader, provides cutting-edge video training within the platform, ensuring seamless learning as you work in modern technology.

Professional Services

We offer comprehensive onboarding for the 3DEXPERIENCE platform, ensuring a smooth start. From setting up your account to software installation, we’ll guide you through every detail for your success.

Frequently Asked Questions

Our extensive library has robots and translators from all major robot manufacturers, and they come pre-configured with their kinematic definition and axis limits defined. Should you not find your particular robot in the library, the Robot Programmer role allows you to import model data and define the kinematics and parameters.

Like all 3DEXPERIENCE tools, the DELMIA roles in these packages are purchased as a named-user term license on either annual or quarterly terms. Each user participating in creating robot programs will need their own license aligned with an email address.

Each user can be assigned different roles based on the functions they need to perform, and each role can be reassigned once every 30 days. The license/role is not tied to a particular robot. You can program multiple robots from different manufacturers using a single license.

The Robot Programmer role is best for arc welding, adhesives application, cutting, and machine tending, along with pick and place applications.

The Robotics Virtual Commissioning Analyst role is for users looking to create accurate workcell simulations of robots, equipment and sensors connected to a PLC program.

If you don’t see a solution for your application, please reach out and we can investigate if another role may be more suitable.

No. The Robot Programmer Professional package can program pick and place, arc weld paths, and create conveyor systems with PLC logic. If you want to generate parts at a certain frequency to determine throughput and use sensors, then choose Robot Programmer Premium for its robot programming and virtual commissioning capabilities.

DELMIA Resources

3D Robot Programming Reduces Costs and Streamlines Production

Learn More

What is the 3DEXPERIENCE? Let's Find Out!

Read Article

The Cost of Disconnected Tools for Manufacturing

Learn More