Consumer Packaged Goods Industry

Packaging Innovation

From Concept to Consumer

Reinvent your brand’s market presence with intelligent design solutions,

and deliver sustainable packaging that captivates consumers.

The Consumer Packaged Goods (CPG) Manufacturing Challenge

Consumer packaged goods (CPG) companies face unprecedented pressures in today’s market. With commodity costs at historic highs, increased regulatory scrutiny, and consumers demanding more sustainable and personalized products, manufacturers must find innovative ways to:

- Accelerate speed to market while maintaining quality standards

- Increase profit margins with fewer resources and rising material costs

- Ensure regulatory compliance across complex global markets

- Implement sustainable practices without sacrificing performance

- Navigate supply chain volatility with agile manufacturing strategies

These challenges require more than traditional solutions — they demand advanced engineering technology that transforms how you design, manufacture, package, and deliver products.

Engineering Success for

CPG Manufacturing Excellence

Go to market with tested, polished, and performance-ready products

DELMIA Factory Simulation

Simulation Software

3D Printing

3D Scanning

Manufacturing-as-a-Service (MaaS)

Industry-Leading Technical Support

Software Solutions That Drive CPG Innovation

Accelerate packaging development and optimize factory operations with intelligent software designed for CPG manufacturing. From sustainable design to regulatory compliance, our solutions help you bring products to market faster.

Advanced FEA Solutions

Advanced Finite Element Analysis (FEA) solutions like 3DEXPERIENCE SIMULIA can accelerate the process of creating optimized, cost-effective, and sustainable packaging designs.

- Integrated simulation shortens product development time and minimizes expensive prototyping.

- Improve sustainability by limiting waste from physical prototypes and minimizing packaging material used through optimization and lightweighting.

3DEXPERIENCE Cloud PLM

Connect global teams to create a single source of truth with this cloud-based PLM system to improve collaboration and efficiency. Streamline & automate documentation across the organization to control data & information, helping comply with complex regulations.

3DEXPERIENCE DELMIA Factory Simulation

Create a digital twin of your packaging factory floor to maximize efficiency and speed to market.

- Simulate and validate factory layout and performance

- Identify bottlenecks, optimize positioning, and improve production rates

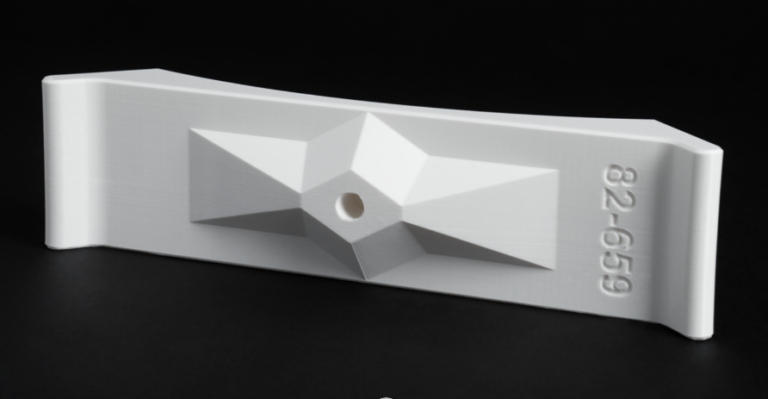

Innovative Small Package Container with Markforged X7

Farason Corporation developed a custom small package container using the Markforged X7 and Onyx material for a major snack food company. This unique solution inverts the packing process to optimize the collection and transport of lightweight packages.

The case study explores how Markforged 3D printing enabled cost-effective, rapid prototyping and enhanced flexibility, ultimately winning the bid and producing over 80 containers for deployment.

Download the case study to learn more about how 3D printing can drive innovative solutions for your business.

Get Your Download Today

While you are waiting, check out our Resource Center or read our Blog!

Markforged FX10

Create an agile factory floor by producing tooling and replacement parts in-house with additive manufacturing, reducing reliance on suppliers. Scale production on the packaging factory floor with the FX10 which offers:

- Dual-material functionality (composite and metal printing) to reduce the need for multiple machines

- Large build volumes

- Food-safe materials

3D Scanners

Leverage 3D scanning for quality control and design validation of packaging. Scanner offerings include:

- Artec Micro II, ideal for small, intricate packaging components

- Artec Spider II and Leo for high-precision scanning of larger packaging designs

- SIMSCAN-E for high-precision packaging details and surfaces

CPG Hardware Solutions

Build manufacturing independence with cutting-edge 3D printing and scanning technologies that reduce supplier dependencies and accelerate production. Create tooling, replacement parts, and quality control systems in-house.

With Hawk Ridge Systems, Success Integration Excellence Expertise Efficiency Reliability Innovation Precision Comes Standard

140+

Engineers on Staff

430+

Combined Certifications

25+

Years in Business

98%

Customer Satisfaction Rate

Related Resources

Food-safe 3D Printing Material: Nylon White FS from Markforged

Read the Blog

3 Ways You Can Design Packaging Using 3D Scans

Watch the Webinar