Company History of Marples Gears Inc.

Founded in 1942, Marples Gears Inc. has a rich history in precision gear manufacturing. Originally involved in building aircraft such as the Aeroneer and gear production, the company was acquired in 1989 by its current ownership – Jim Phillips. Today, it operates as an S corporation as a member of the AGMA, with AS9100-D & ISO 9001:2016 registration, specializing in high-precision gears, splines, and complex CNC components for demanding industries like commercial aerospace, space, and medical industries.

“We have close to 50 thousand parts orbiting Earth right now that we made in our factory. I’m sure some of them probably have fallen back to Earth by now.” -Marples Gears President, Allen Sterris

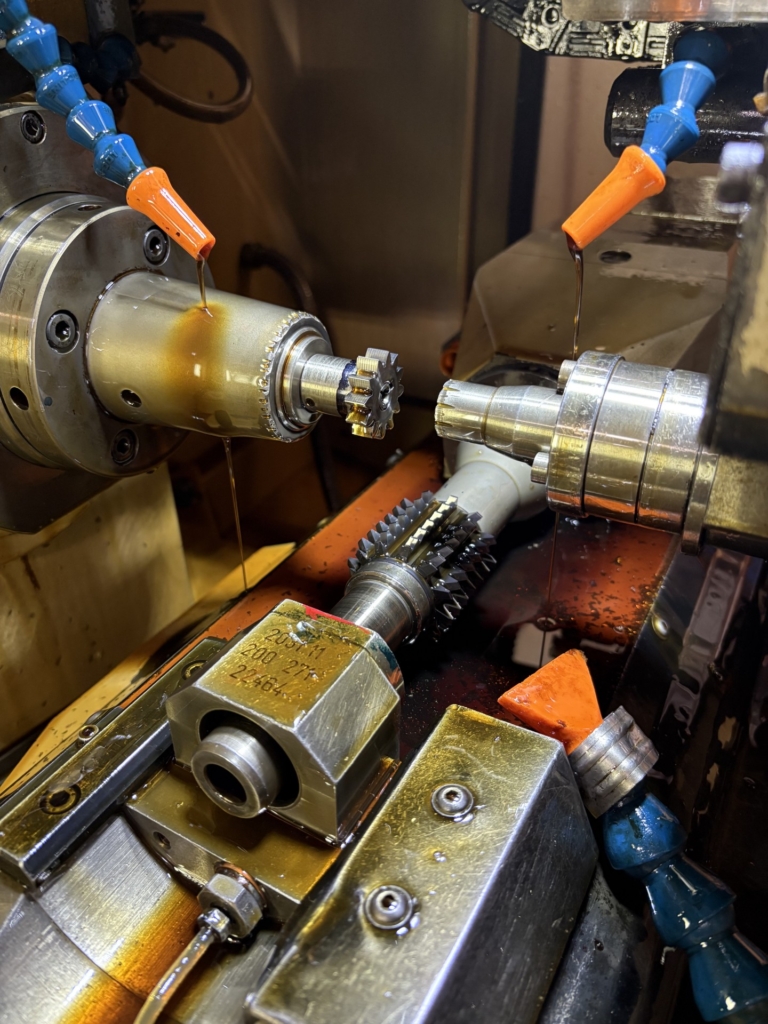

US-based manufacturing company, Marples Gears makes epicyclic gear trains including planet gears, ring gears, sun gears, and also helical gears and rotor shafts, with a focus on high-precision fine pitch gears. They manage the full production process, from bar stock to finished components, including managing specialized processes like passivation and heat treat.

Notable Impacts:

- Close to 50 thousand parts orbiting Earth in satellites and spacecraft

- Gears on Mars rovers used for drilling and sample collection

- Historical contributions to historical defense projects

- Precision components for medical instruments like bone drills and grinders

- Collaboration with organizations like JPL, Los Alamos Labs, and major aerospace firms

Challenges

Marples Gears focuses on ultra-high precision manufacturing that few shops can handle with challenges like:

- Achieving tolerances and complexities involving heat treatment, chemistry, and processes beyond average machine shops

- Managing dependencies across departments to maintain schedules in an extremely fast-paced environment

- Handling diverse materials and outside processes like heat treatment, passivation, NDT and special coatings

- Scaling production while maintaining quality for space and defense applications

- Accurate quoting and cycle time estimation for new jobs

How Marples Gears Use SOLIDWORKS, CAMWorks, CNC Machining, CMM, and More for Precision Manufacturing and Process Improvement

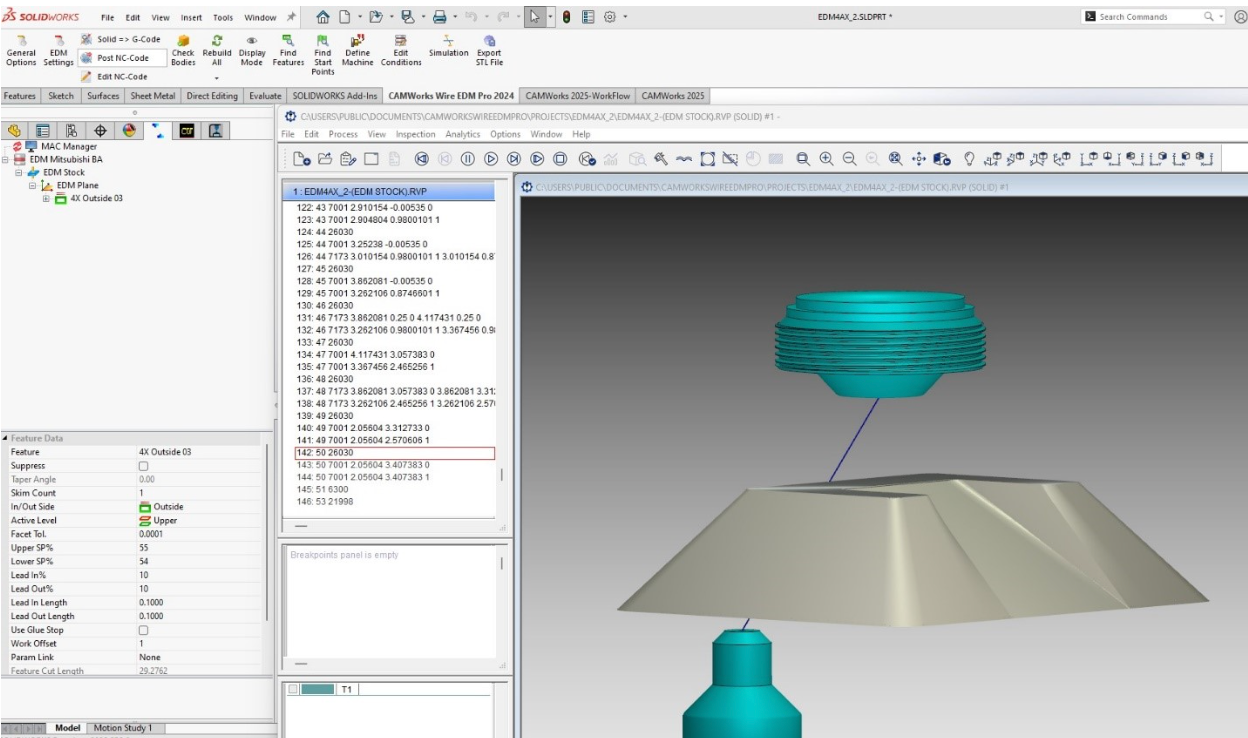

Marples Gears leverages SOLIDWORKS integrated with CAMWorks for end-to-end design, programming, and production. They create 3D models from drawings or customer files, program toolpaths, generate custom setup sheets, and use simulations for visualization. This setup supports quoting, inspection, and fixture design to boost efficiency.

Key Wins

3D Modeling and Programming Integration:

They import or create 3D models in SOLIDWORKS, then program in CAMWorks for precise toolpaths. This streamlines production, especially for complex gears, reducing setup time and errors.

“I take all the detailed drawings that we have when we’re working on a project and then I’ll either create the 3D model from scratch based on the drawing or we’ll request the 3D model from the client and then open it with SOLIDWORKS, and then program it in CAMWorks with the 3D modeling. We can design custom fixtures and custom tools around the component all within the same interface using CAMWorks, faster than some other software packages.” – Corey, Vice President at Marples Gears Inc.

Custom Setup Sheets:

Using the advanced setup sheet module in CAMWorks, they generate sheets with 3D models, pictures, and tool lists, aiding shop floor operators.

“We’ve purchased the custom setup sheet module… and I use that to create the setup sheets for the production staff, which is nice because you can actually print out documents that include a 3D model image, tool list, operation steps, images of the toolpaths, setup origins, and unique tooling, all with only a few clicks.” – Corey, Vice President at Marples Gears Inc.

Fixture Design for Productivity:

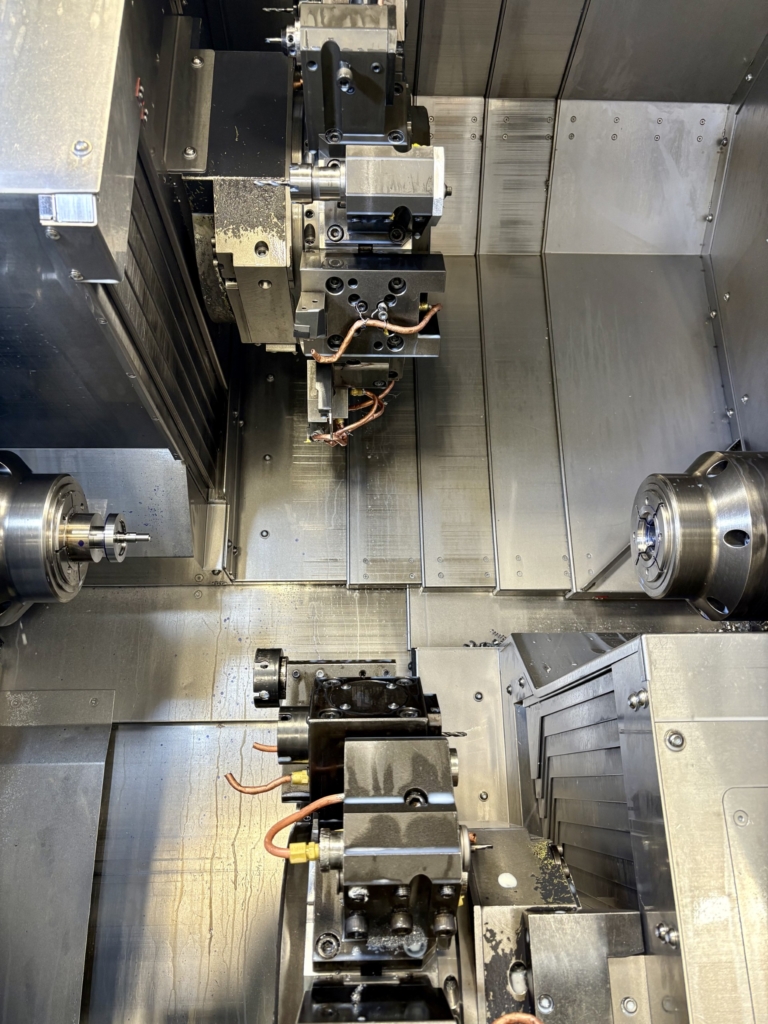

SOLIDWORKS is used to design fixtures and pallets for holding multiple parts, increasing efficiency in CNC milling and turning, as well as creating operational step-by-step MFG detailed drawings, analyzing 3D dimensions, and evaluating material properties.

Fixture and Tooling Design:

They’re also using SOLIDWORKS and CAMWorks to design custom tooling for gear production and complex geometries, and fixtures such as pallets for the Milling Department, as well as custom toolholders for the Lathe Department to increase CNC milling/turning productivity.

Visualization and Simulation:

Programs are simulated in CAMWorks and shown to operators for better understanding of toolpaths, especially for multi-axis parts.

“We’re also using CAMWorks to help the team visualize better. When we show the production staff the CNC simulation and the step-by-step of how the tool path is working on the part it makes more sense to them.”

– Corey, Vice President at Marples Gears Inc.

Quoting and Inspection:

Models are used in Mitutoyo Cosmos software for CMM inspections and pre-programming new jobs to get accurate cycle times for quotes. They use SOLIDWORKS Drawings for CMM instruction, to check certain aspects of the drawing, and then take the SOLIDWORKS generated model into Mitutoyo Cosmos to inspect parts on the CMM.

“And then we’re also using these tools for quoting jobs. When it’s a new job, I’ll program it ahead of time because it’s so easy in CAMWorks and we can produce accurate numbers to put up against the cycle times. It really helps for being more precise on our quotations.” – Corey, Vice President at Marples Gears Inc.

Why Hawk Ridge Systems?

Marples Gears has been with Hawk Ridge Systems for over a decade, using SOLIDWORKS, Mastercam, and now CAMWorks. They value the integration and support and love how quickly Hawk Ridge support staff responds to in-depth questions, and their willingness to do a video chat to make sure the answers are specific if needed.

What’s Next for Marples Gears Inc.?

These are some key future state objectives:

- Expanding to more tier-one clients like Lockheed Martin and defense contractors

- Investing in new equipment to handle more complex projects & increasing demands in the manufacturing environment and increase capacity

- Employee investment, expansion of team

- Growing space and aerospace business leveraging their reputation

“We are ready, willing, and able to take on new business and want that. We invest in ourselves. We just recently hired a project manager to help grow the business. We’re looking at new equipment. We’re always looking to hire more skilled machinists.” – Corey D’Arezzo, Vice President at Marples Gears

Interested in how other companies are using SOLIDWORKS and CAMWorks? Check out more customer stories like Speedway Motorsports and Knapheide.

Download the Marples Gears full customer story to learn more.