Why Machine Shops Should Add Metal 3D Printing

On the fence about adding a metal 3D printer to your floor? Alongside your CNC mills, lathes, and grinders, metal 3D printers help you build hybrid additive-subtractive workflows that are faster and superior. Adding this key technology to your shop floor means you win more low-volume custom work, reduce lead times, and differentiate your shop in a competitive market.

From Prohibitive Costs to Shop-Floor Accessible Technology

15 years ago, metal 3D printing was out of reach for most shops financially. We’re talking 600k for the printer alone, plus ballooning infrastructure costs (inert gas, safety systems, heat treatment).

Today, it’s affordable and accessible for reliable end-use production. Systems like the Markforged Metal X eliminate loose powder hazards and require minimal specialized infrastructure. Complete setups including printer, wash station, and sinter furnace often run in the $150,000–$250,000 range.

The bound powder filament process (inspired by metal injection molding) is safe and simple:

- No respirators or full PPE needed — handles filament like plastic

- Three-step workflow: Print the green part → Wash to debind → Sinter to full density (99%+)

Materials include 17-4PH/316L stainless, H13/D2 tool steel, Inconel 625, and copper — perfect for tooling, fixtures, and functional parts.

Post-Processing Workflow to Finish Metal 3D-printed Tools

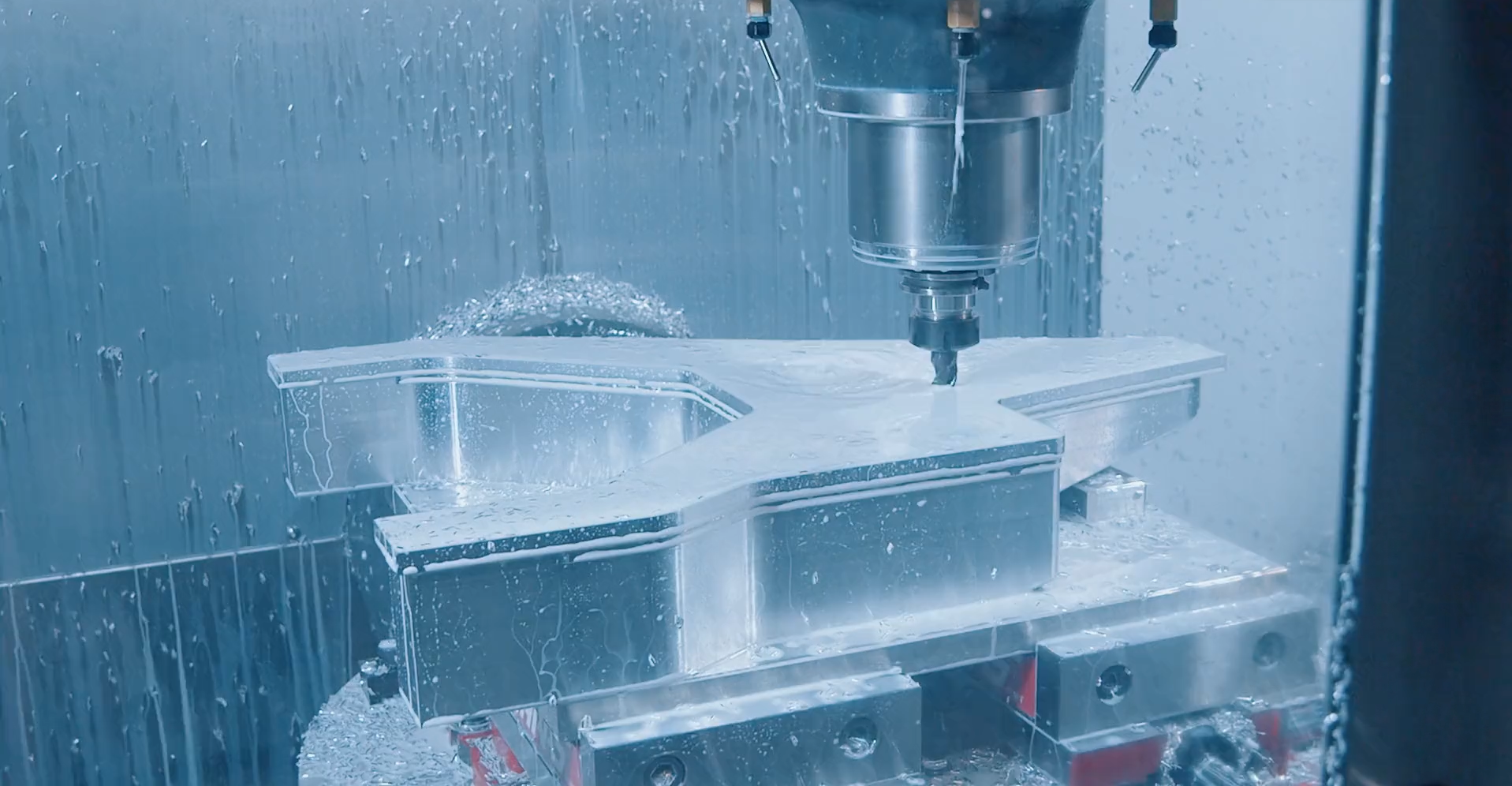

The real power for machine shops comes from integrating 3D printing with your existing CNC processes. Print the near-net-shape part with internal features (like conformal cooling channels or lightweight infill), then finish on your CNC machines for precision.

Tools like CAMWorks (integrated directly in SOLIDWORKS) make this seamless:

- Import the printed part as an assembly with stock, chuck, and fixtures

- Automatically recognize features (holes to drill/tap, faces to mill) on the as-printed part

- Generate optimized toolpaths quickly

- Run full simulations to check for collisions on cutters, holders, and machine axes — including advanced digital twins of your actual machine (e.g., with tilting/rotating heads via tools like Eureka)

- Verify G-code for over-limits or crashes before sending to the floor

This “Print, Mill, Repeat” approach minimizes programming time, avoids shop-floor trial-and-error, and ensures safe, efficient finishing — turning complex hybrid jobs into routine production.

Hybrid Metal 3D Print + CNC Workflow

- Design: Model complex features like conformal coolant channels with CAD

- Print: Print green part using bound metal filament (Markforged Metal X)

- Wash: Solvent debind to remove wax binder

- Sinter: Sinter to densify into pure metal part

- Remove Supports: Break off raft and ceramic-separated supports manually

- CNC Finish: Use CAMWorks to program, simulate, and machine precision features (faces, holes)

Real-World Proof: Guhring UK’s Custom Cutting Tool Transformation

Global cutting tool manufacturer Guhring (with facilities like Guhring UK serving major clients) provides a textbook example for machine shops.

They faced long lead times (4-8 weeks) and high costs for low-volume custom rotary tools (drills, reamers, face mills) using traditional machining.

By adding the Markforged Metal X, they now print tool bodies in H13 tool steel with impossible conventional features:

- Conformal coolant channels — curved paths directing fluid exactly to cutting tips for longer tool life

- Sparse infill — reducing weight by up to 60% while damping vibration and chatter

- Integrated designs eliminating assemblies

- Finish with CNC grinding/tapping as needed

Results: 75% faster lead times (down to 1 week or even 5 days), significant cost savings, lighter/higher performance tools, and the ability to serve smaller customers with quick iterations.

The Competitive Edge for Your Shop

If you’re debating the investment, this accessible, safe technology — paired with CAM tools like CAMWorks — can transform your shop from traditional machining to a modern hybrid powerhouse. It’s a proven way to boost profitability and capture new business.

Adding a metal 3D printer like the Metal X creates smarter workflows that can:

- Handle complex/low-volume customs profitably

- Reduce setups and material waste on your CNCs

- Deliver better-performing parts (e.g., cooled molds, lightweight fixtures)

For more on CNC and 3D printer workflows, check out the on-demand Hawk Ridge Systems presentation at the D2M Conference: “Print, Mill, Repeat: Smarter Workflows for the Machine Shop.”