Aerospace and Defense

You've Got Questions, We've Got Answers

While you are waiting, check out our Resource Center or read our Blog!

Design to Manufacture in Aerospace

Aerospace and Defense companies are utilizing additive manufacturing to build lightweight, yet durable components and functional end-use parts made from composites and metal.

The ability to reverse engineer parts through scanning, the use of distributed manufacturing, and small batch processing all ensure maintenance, repair, and operations go smoothly and minimize supply chain disruptions.

Behind the scenes, the software, services, and hardware utilized by these companies support initiatives to improve life on Earth and beyond the stars – that level of better engineering starts here.

Seasoned Experts with Advanced Technology and Support

Iterate & Innovate with Agility, Speed & Precision

Iterate fast, reduce supply chain dependence, test part performance and produce lightweight, robust parts quicker than traditional manufacturing.

Meet Safety Requirements & Regulatory Compliance

Get the right hardware, software (on-premises or cloud), and services for advanced simulation, material traceability, data management, and documentation to meet safety and regulatory specifications effortlessly.

Knowledgeable Engineers with Industry Experience

Receive comprehensive nationwide support from in-house engineers with extensive experience and expertise in aerospace.

Additive Manufacturing for Aerospace

Markforged FX20

Create large, robust, yet extremely lightweight prototypes or end-use parts that can be used for cabin components, brackets, harnesses and sensor mounts.

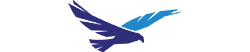

Markforged Eiger Software

Artec 3D Scanners

Aerospace & Defense Software

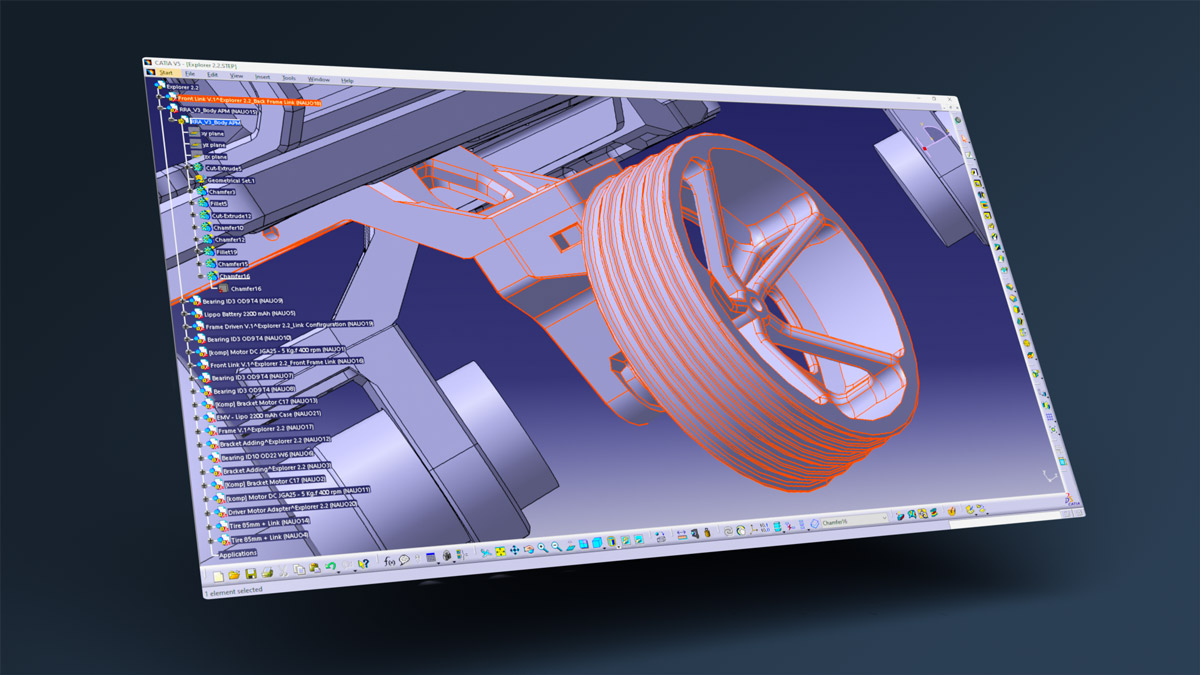

Mechanical Design

Effortlessly navigate the intricacies of advanced surfacing techniques and handle large, complex assemblies with precision, using powerful design tools, including CATIA.

PDM and PLM Solutions

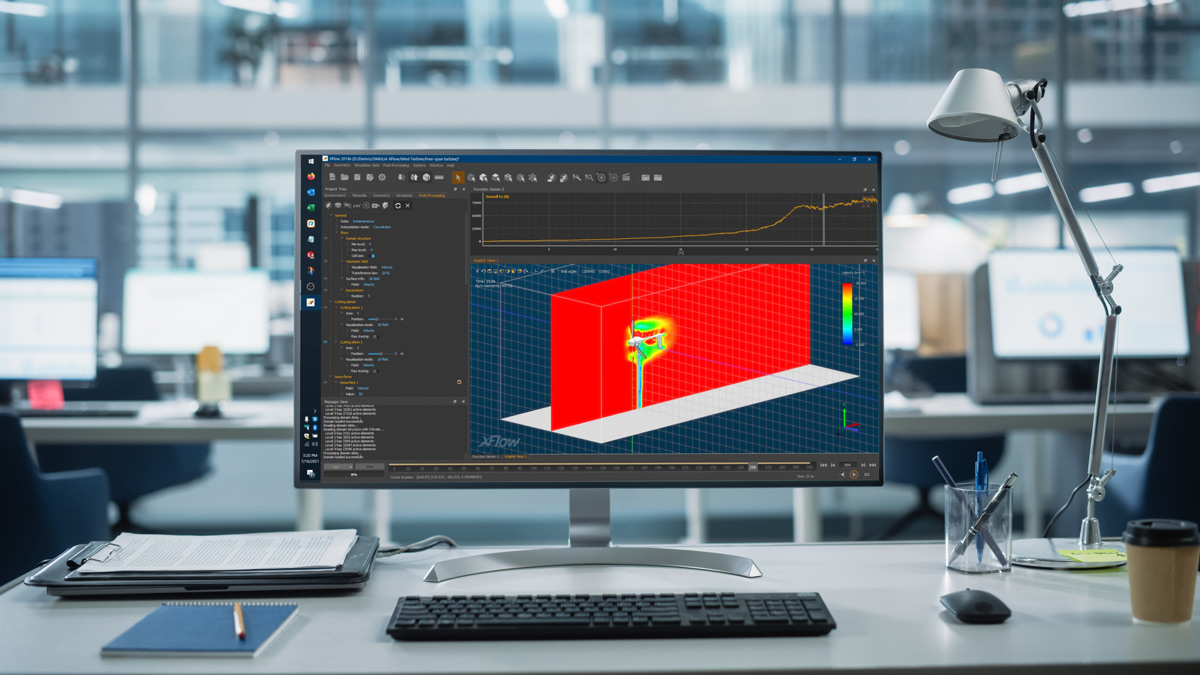

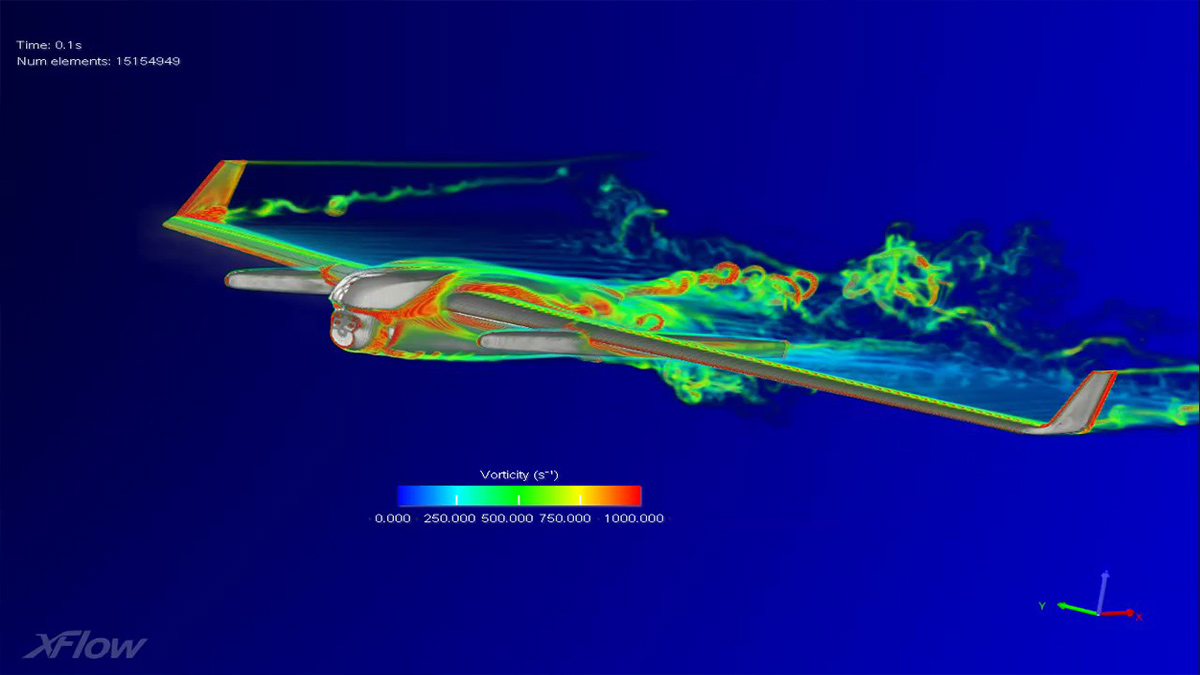

Computational Fluid Dynamics

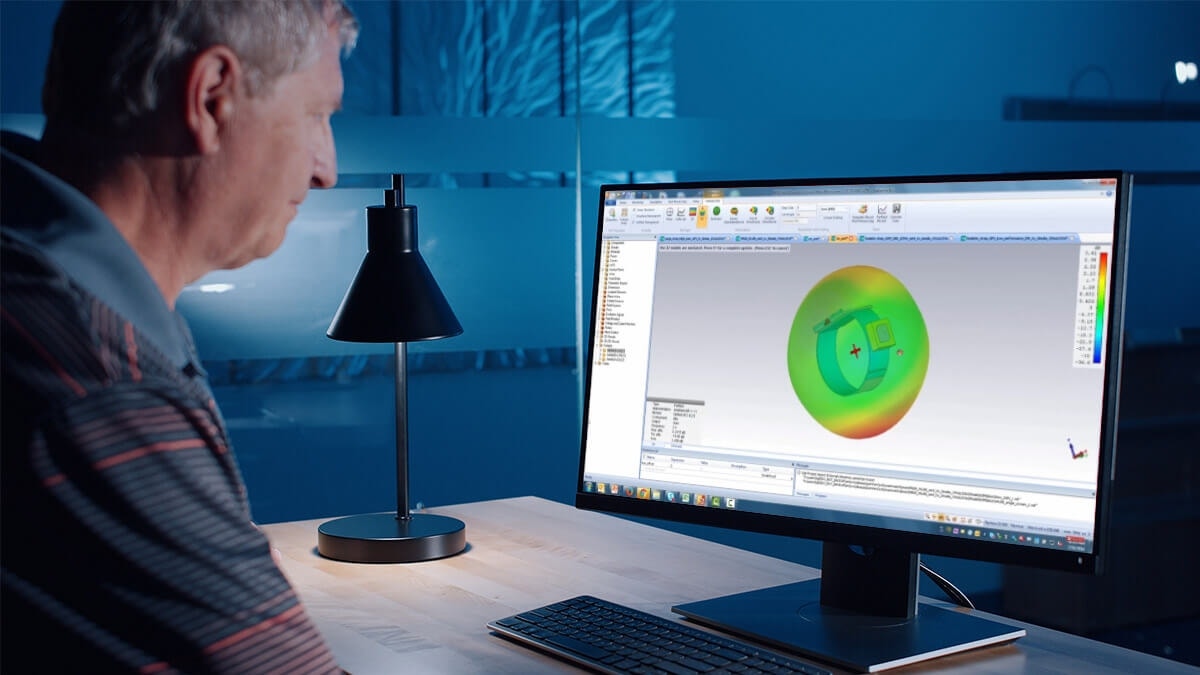

Advanced Structural Simulation

Quickly perform linear dynamic studies for vibration and shock testing.

Electromagnetic Simulation

Integrated Modeling and Simulation

Enterprise Services

Design & Engineering Services

The Future of Moon Exploration

Embark on a journey of discovery with Astrobotic, the pioneering force behind the world’s first privately owned spacecraft, as it blazes a trail in affordable missions to the moon.

Delve into the realm of groundbreaking technology and visionary missions, poised to unlock the mysteries of lunar exploration and propel humanity’s understanding of our celestial neighbor to new heights. Join us as we venture beyond the confines of Earth, driven by innovation and a relentless quest for knowledge, towards a future where the wonders of space are within reach like never before.

Our Customers in Aerospace & Defense

Manufacturing Solutions for Aerospace & Defense

At Hawk Ridge Systems, we offer two solutions for your manufacturing needs: 1) with our manufacturing partner and 2) by purchasing the right tools for your in-house manufacturing team.

For organizations without an in-house manufacturing team, our partner, A3D Manufacturing, offers end-to-end manufacturing solutions, such as various additive manufacturing methods and prototyping, post-processing services, CNC machining, injection molding and cast urethane.

Services & Customer Benefits

Technical Support

Our technical support team is comprised of mechanical engineers, electrical engineers, and computing specialists who provide best-in-class on-call support and Ask-an-Expert sessions when you need it the most.

Unmatched Training

We’re one of the largest engineering training providers in the world, offering both online and on-demand training so your team knows how to get the most out of your software.

Professional Services

Our dedicated Services team ensures a swift start with our design solutions, offering complete implementation, onboarding, consulting, and efficient upgrades for new mechanical design software.

Subscription Support

Frequently Asked Questions

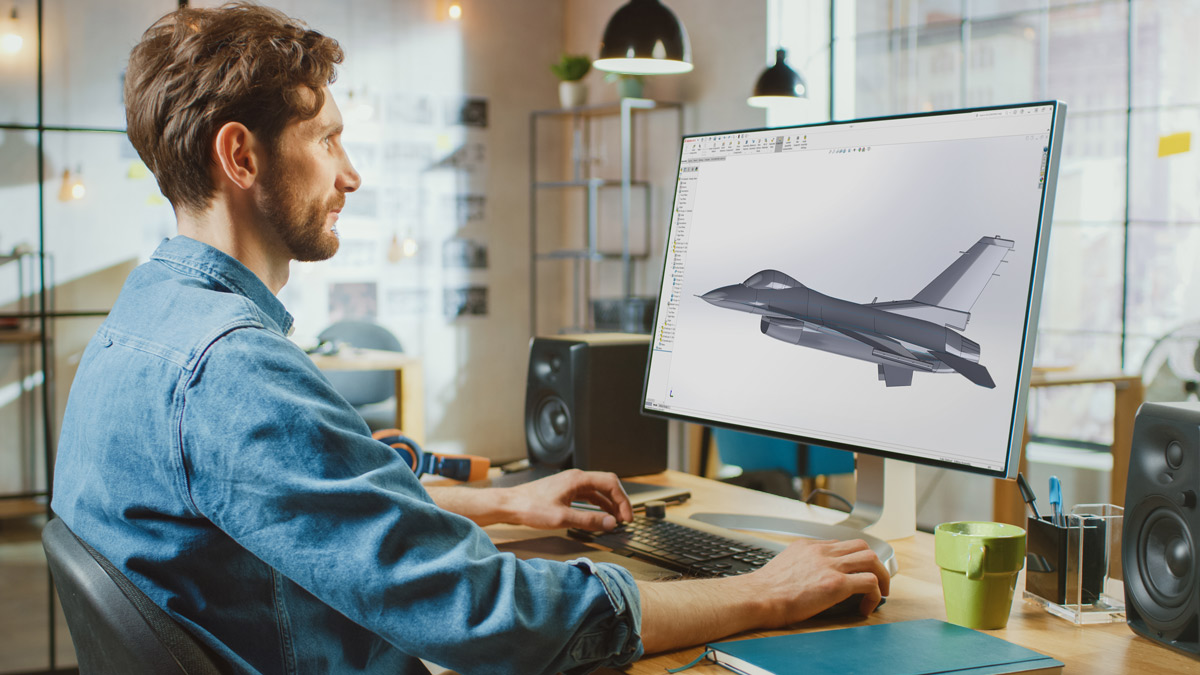

Aerospace and defense companies use best-in-class software like CATIA, SOLIDWORKS and many other adjacent technologies. Popular organizations like NASA, SpaceX and Lockheed Martin use CATIA and SOLIDWORKS.

In addition to CAD software, these companies also use data management solutions, simulation and analysis tools and MES (Manufacturing Execution Software.)

Data management solutions are ideal for any company. For the aerospace industry, these solutions provide one common documentation system, allowing teams to easily trace every approval and person who operated on the aircraft — down to a single bolt.

Having a well-documented system also helps product development teams meet strict regulatory requirements set by top aviation authorities like the Federal Aviation Administration (FAA) or the European Union Aviation Safety Agency (EASA).

Aerospace engineers can benefit from various simulation software because they have numerous study types that help ensure designs and parts meet safety and performance requirements.

One of the most challenging aspects of aerospace engineering is designing for extreme conditions, such as high altitudes, low temperatures, high speeds and harsh environments. These conditions affect the performance, durability and safety of aerospace systems and components, and require careful consideration of factors, such as aerodynamics, thermodynamics, materials and structures.

For example, aerospace engineers need to design aircraft and spacecraft that can withstand high dynamic pressures, thermal stresses, vibration, shock and fatigue, while also minimizing drag, weight and noise. To achieve this, aerospace engineers use advanced computational tools, simulation models and experimental methods to analyze and optimize their designs, and test them in various facilities, such as wind tunnels, vacuum chambers and flight simulators.

Aerospace and defense companies who are early adopters of additive manufacturing range from smaller organizations who use it to lightweight drone parts to large, global companies that use it across their manufacturing lines.

Here are some examples:

- Boeing uses SLS printing to make 150 different parts for the F/A-18E Super Hornet aircraft which is used by air forces around the globe.

- Cabin Management Solutions and the U.S. Department of Defense both leverage 3D printing to replace low-volume, high-value parts for aircraft at lower costs and accelerated lead times.

- Hangar One Avionics saves 30 minutes per part using part inspection software which makes traceability for FAA compliance easier.

Hawk Ridge Systems recommends the Markforged FX10 and FX20 and the HP Multi-Jet Fusion 5200 as the best-in-class 3D printers for aerospace and defense organizations. These printers are used by companies like Boeing, Cabin Management Solutions and Ascendance Flight Technologies.

Additive manufacturing helps the propulsion and space launch industry by offering the ability to consolidate multiple subcomponents into a single 3D-printed component.

This consolidation not only reduces the costs of manufacturing, but also contributes to weight reduction and improved system performance. By leveraging additive manufacturing and consulting services, aerospace manufacturers can optimize their production processes and achieve significant cost savings.

Implementing additive manufacturing can result in a strong return on investment (ROI) for aerospace manufacturers. By reducing costs, improving efficiency and enhancing performance, additive manufacturing offers significant financial advantages for aerospace and defense companies.

One of the key advantages of additive manufacturing in aerospace and defense is the ability to produce lightweight brackets. By leveraging advanced direct metal printing and topological optimization, aerospace manufacturers can design highly complex brackets that maintain or even improve material strength while reducing operational costs. This not only enables greater fuel efficiency, but also contributes to overall weight reduction, fewer bolted and welded joints, and improved system performance.

Traditionally, investment casting patterns required expensive injection molding tooling. However, additive manufacturing offers a cost-effective alternative by enabling the production of 3D printed molds in a fraction of the time and cost. Aerospace parts manufacturers can now move directly from CAD to casting patterns, with fewer design limitations and the ability to create hollow patterns with greater design complexity. This advancement in additive manufacturing technology accelerates production timelines and reduces costs.

Aerospace & Defense Resources

Additive Manufacturing and Aerospace

Download Whitepaper

State of the Industry Report for Aerospace

Download Report

Predicting Lift and Drag with SOLIDWORKS and SIMULIA

Read Article