High Tech & Electronics Industry

Powering Innovation,

Engineering the Future

From cutting-edge designs to seamless manufacturing,

we empower high-tech innovators to bring their boldest ideas to life.

The Future of High Tech & Electronics Design & Manufacturing

Product miniaturization, mass customization, and consumer demand for more powerful, easily upgradable high-tech devices and electronics are table stakes for technology companies. What gives your company the edge?

Leading technology companies make sure their products are within regulation, sustainably developed, and most of all, dependable.

They’re tasked with:

- Testing common performance challenges like signal integrity, heat dissipation, and electromagnetic interference

- Evaluating and minimizing the environmental impact of the manufacturing process

- Designing increasingly smaller and smaller components without sacrificing performance or energy consumption

Smaller, Better, Faster:

Solutions for the Future of Tech

Go to market with tested, polished, and performance-ready products

Design Software

Simulation Software

3D Printing

3D Scanning

Manufacturing-as-a-Service (MaaS)

Industry-Leading Technical Support

Why Companies Use SOLIDWORKS to Design High Tech

If you’re designing cutting-edge tech products, you need tools that keep up with the demands of modern engineering. SOLIDWORKS isn’t just a CAD program — it’s a full-fledged design, simulation, and validation ecosystem that makes product development faster, smarter, and more cost-effective.

With powerful built-in simulation tools, seamless integration with circuit board design software, and access to cloud-based collaboration on the 3DEXPERIENCE platform, SOLIDWORKS gives engineers everything they need to bring high-performance products to market with confidence.

High Tech Software Solutions

Utilize the same software tools used by industry leaders to create high–performing, long-lasting electronic devices.

SOLIDWORKS CAD

Accelerate time to market by using connected tools for all parts of the design process.

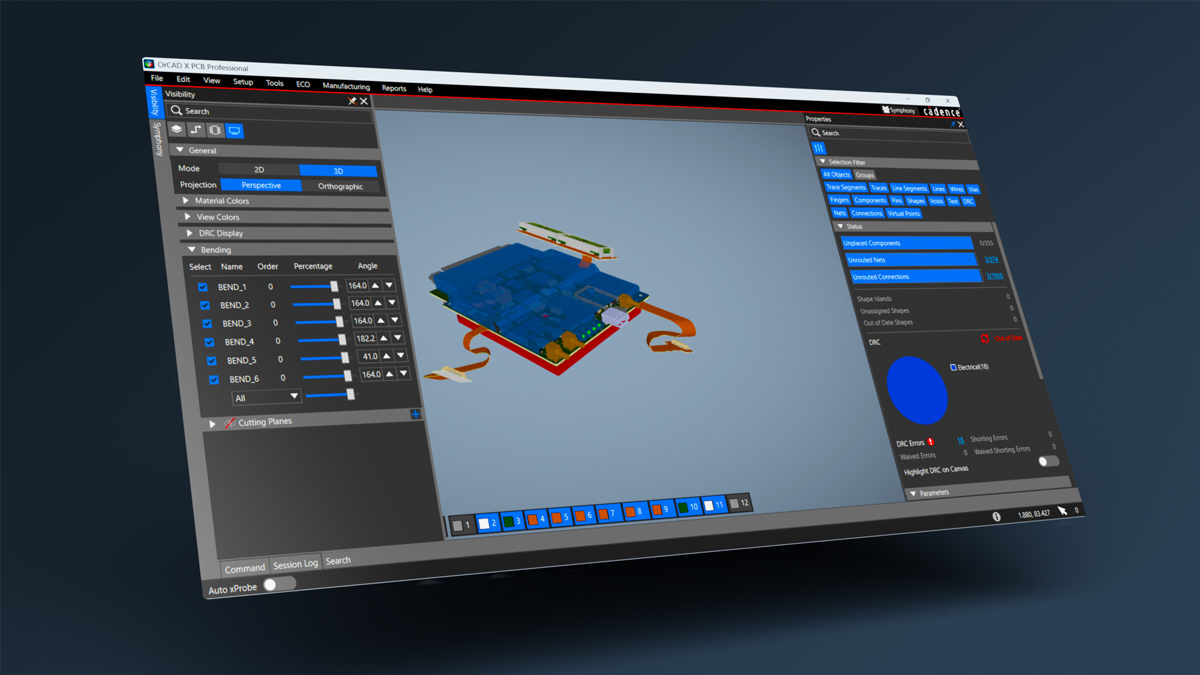

Electrical Design

Create an uninterrupted workflow between SOLIDWORKS CAD and electrical schematic design, PCB design, or 3D electrical wire routing.

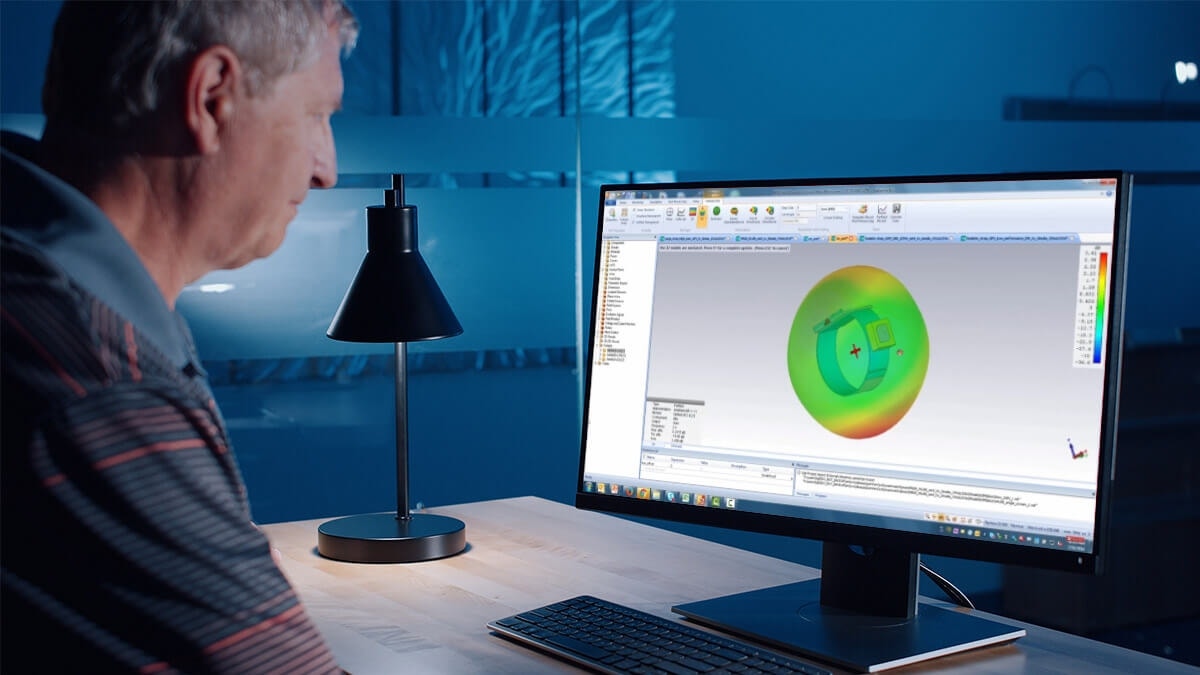

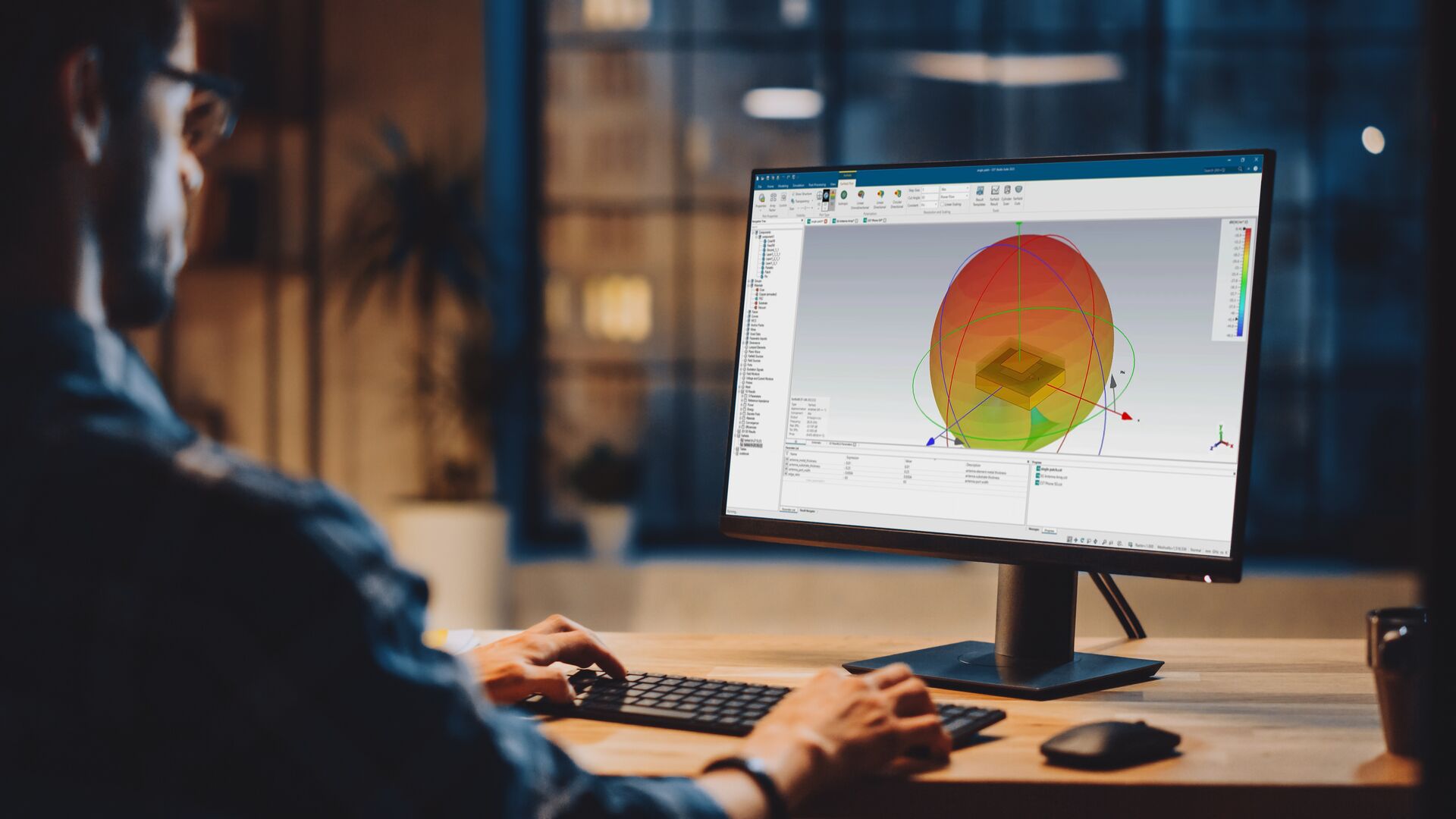

Electromagnetic Simulation

Ensure PCB performance, test for signal integrity, and more on complex systems.

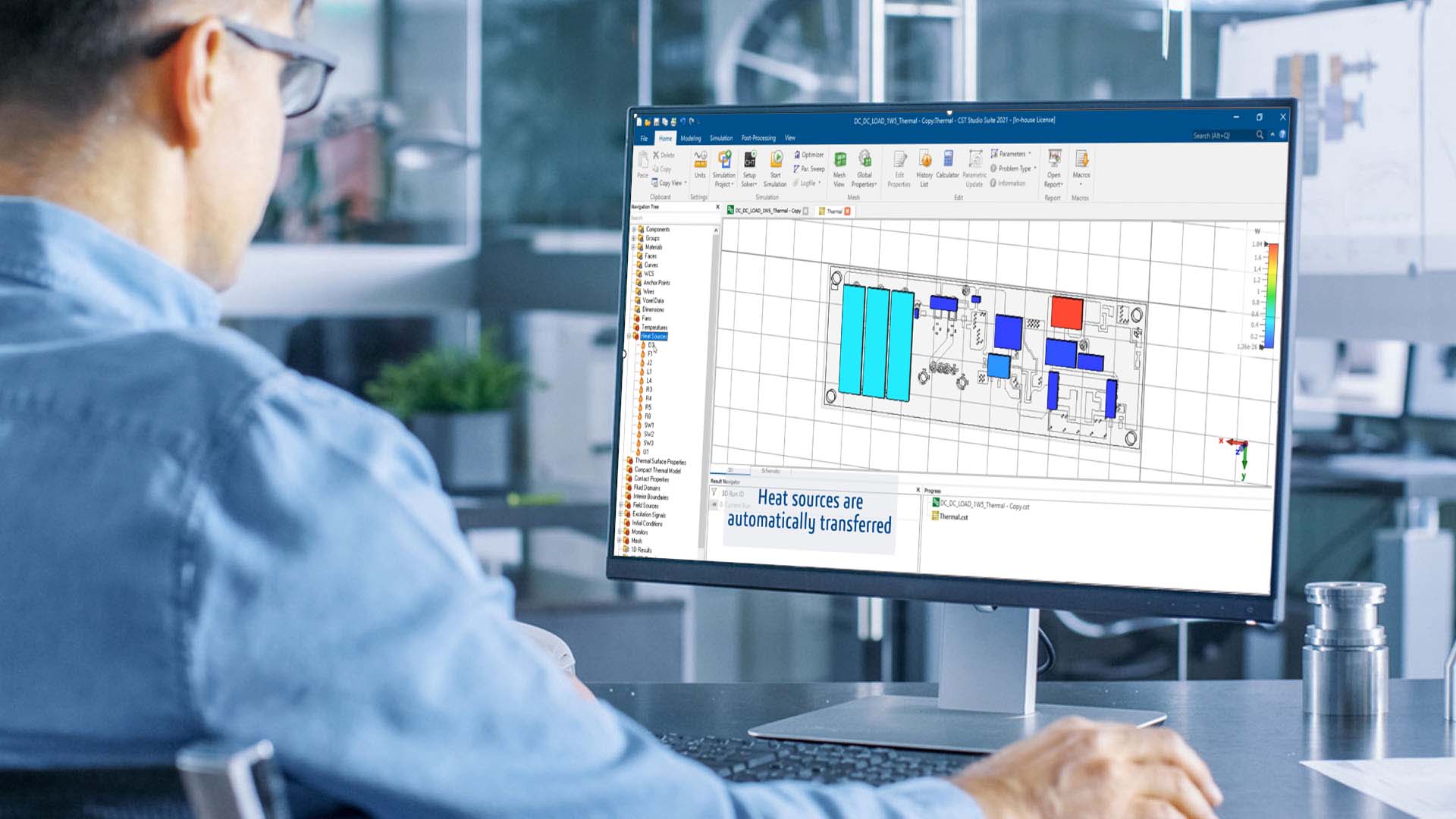

Thermal Simulation (CFD)

Improve electronic performance by testing cooling and thermal challenges.

Structural Simulation (FEA)

Simulate shock, vibration, and impact during the design process.

3DEXPERIENCE DELMIA Factory Simulation

Simulate factory floor layout for optimized performance.

PDM/PLM Solutions

Effectively capture, organize, and utilize data to streamline product development.

How CST Studio Suite is Improving 5G Antennae Design

With so much data flying through the air, designing 5G antennae that get these signals to the right place with minimal interference to or from the surrounding environment is an ever-present challenge. One option for predicting the behavior of these signals is to use an electromagnetics analysis software like SIMULIA CST Studio Suite, which enables users to optimize these elements in a robust simulation environment and ensure the products pass their required physical testing.

Markforged 3D Printers

Print strong electronics parts with ESD-safe materials and high-quality surface finishes with materials like Onyx or print copper parts with the Metal X.

Formlabs 3D Printers

Create complex geometries for low-volume production with ESD-safe resin materials.

3D Scanners

Ensure quality and safety with high-resolution scans of PCB post assemblies.

High Tech Hardware Solutions

Get hardware solutions to scan and build electronic components and enclosures.

North American Manufacturing,

On Demand

Get high-performance, high-quality parts, fast with local, North American manufacturing services. Manufacturing-as-a-service (Maas) providers offer 3D printing, and traditional manufacturing services so you can optimize costs, speed up production, and manufacture your parts and prototypes sustainably and locally.

With MaaS, you can:

- Optimize manufacturing workflows

- Lower operational costs

- Scale your production to meet demand

With Hawk Ridge Systems, Success Integration Excellence Expertise Efficiency Reliability Innovation Precision Comes Standard

140+

Engineers on Staff

430+

Combined Certifications

25+

Years in Business

98%

Customer Satisfaction Rate

Related Resources

How to Enhance Your Design Lifecycles for Consumer Electronics with SIMULIA CST

Read the Blog

EMAG Meets Thermal: A Beginner’s Guide for Electrical Engineers with SIMULIA CST Suite

Read More