Automotive & Transportation Industry

Driving Automotive

Innovation Forward

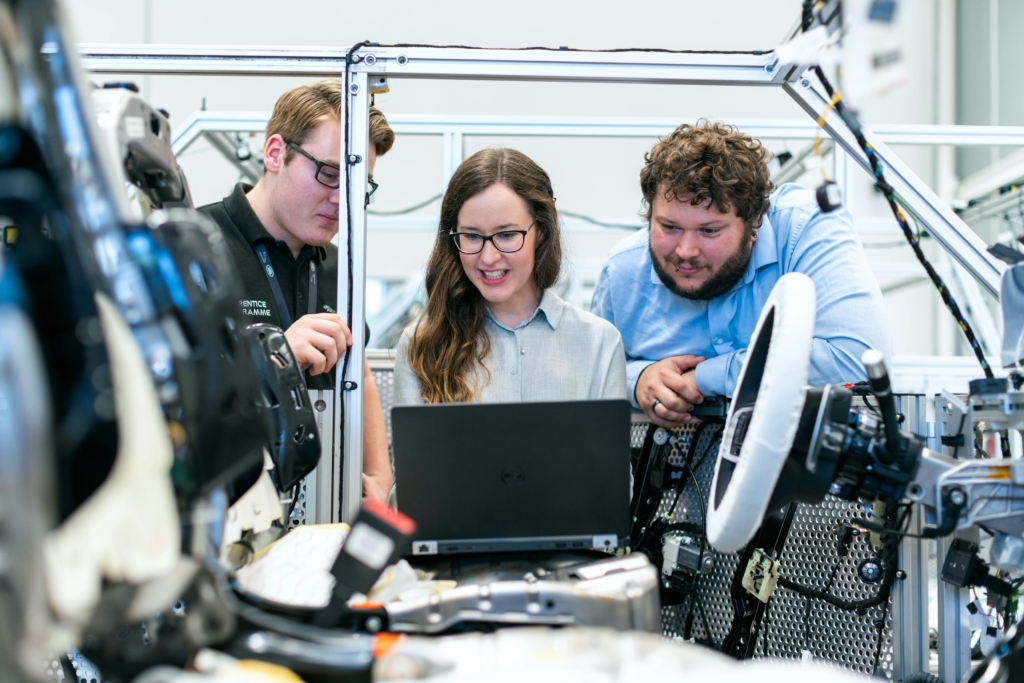

Discover next-gen engineering solutions and manufacturing technology

for modern-day vehicles and motorsports.

The Roadmap to Smarter Automotive Design

Packed with expert recommendations, real-world examples, and strategies to boost efficiency, slash costs, and speed up innovation, this guide was engineered specifically for companies in the automotive aftermarket space.

The Future of Transportation Manufacturing is Here

Ready to accelerate automotive transformation? Autonomous vehicles, customization, and sustainability are revolutionizing how we design and build across automotive, racing, and supplier industries.

What gives you the competitive edge:

- Smarter Design: Tackle complex challenges through seamless team collaboration

- Optimized Production: Boost efficiency and supply chain resilience with the right technologies

- Proven Solutions: Overcome labor shortages and hit the market faster with industry-leading software and 3D printing

- On-Demand Manufacturing: Extend your capabilities through our trusted Manufacturing-as-a-Service (MaaS) partner network—scale quickly, without overextending resources

Why wait? Innovate faster. Reduce complexity. Build with confidence.

Drive Innovation at Every Turn

Accelerate time to market, collaborate with ease, and ensure the manufacturability of your products.

Design & Simulation Software

3D Printing

3D Scanning

Post-Processing Technologies

Manufacturing-as-a-Service (MaaS)

Industry-Leading Technical Support

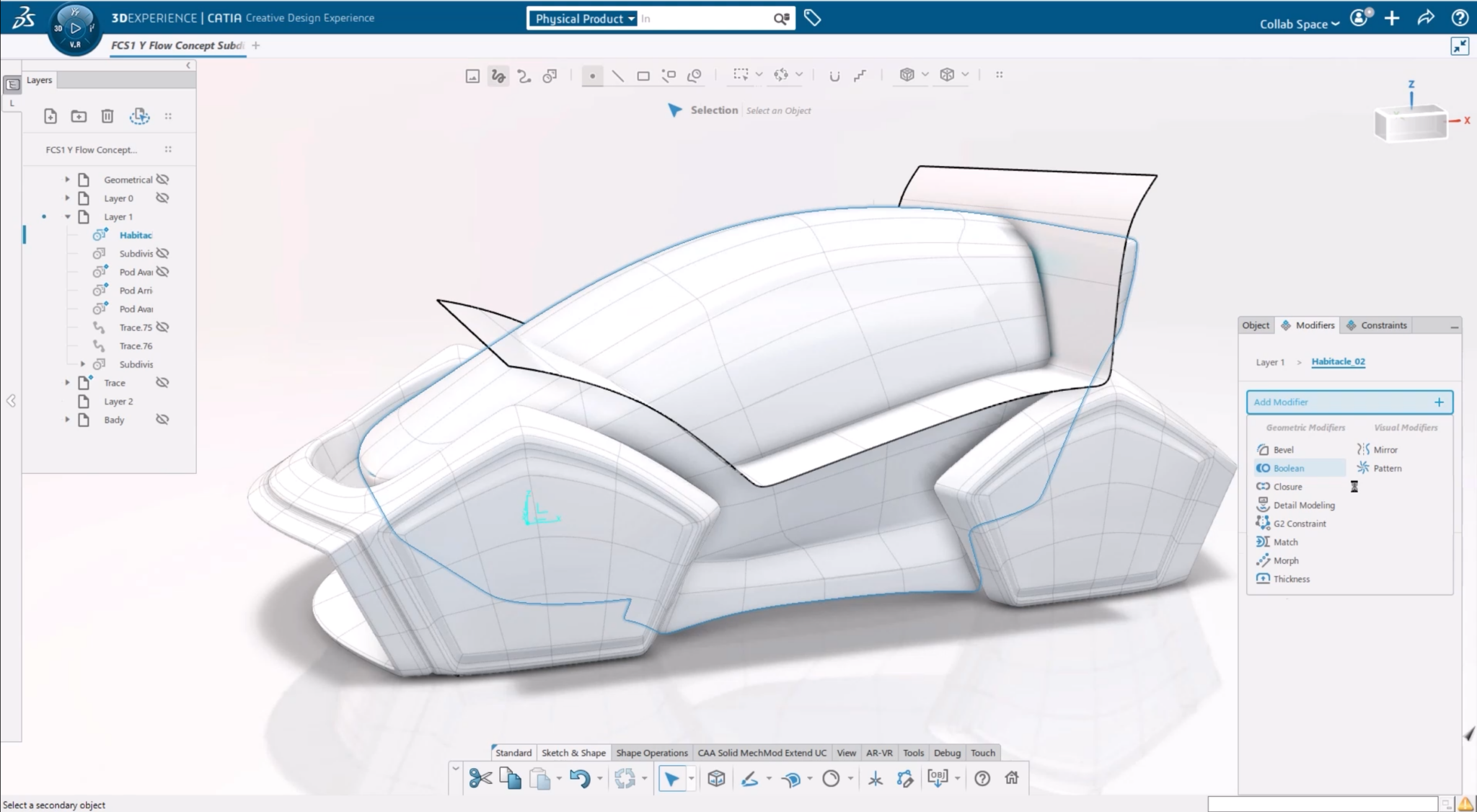

Software Solutions for Tomorrow's Vehicles

Hawk Ridge Systems delivers powerful solutions built specifically for transportation’s toughest challenges.

Mechanical Design

Design and validate automotive components with the industry-standard design-to-manufacturing ecosystem.

FEA Simulation

Simulate real-world scenarios, from vibration analysis to crash tests, with SOLIDWORKS Simulation and 3DEXPERIENCE SIMULIA.

CFD Simulation

Optimize designs for heat and airflow challenges with precision using SOLIDWORKS Flow Simulation and 3DEXPERIENCE SIMULIA.

Electromagnetic Simulation

Validate the placement of antennas for autonomous and connected vehicles using SIMULIA CST.

Data Management

Leverage PDM and PLM solutions to streamline product development workflows for faster time to market and regulatory compliance.

Automation

Use DriveWorks to customize slightly varied parts and components.

CNC Programming

Automate manufacturing with CAMWorks and DELMIA Machining.

Robotic Automation

Automate machining cells for high-volume robotic welding with DELMIA Robotics.

Factory Simulation

Speed up manufacturing efficiency on the factory floor with DELMIA Factory Simulation.

Electrical Design

Create collaborative workflows between MCAD and ECAD teams with integrated solutions that help to reduce errors and manual rework, helping you bring products to market faster.

From Zero to Sixty: Success in Action

Discover how leaders in automotive are driving results with Hawk Ridge Systems.

Pushing the Limits On and Off the Track

Today, the team has drastically reduced time and costs, streamlined processes with rapid design modifications and maximized tool life for years to come using CAMWorks VoluMill.

See how our solutions can help you reduce time and costs.

3D Printing More Power

For more than 20 years EDR Performance has been servicing racing motorcycles to perform better on the track. They increased vehicle performance even more when they implemented Markforged 3D printers. Using Mark Two printers they customize parts like velocity stacks to give racers the exact results they need.

Custom parts, winning results. Discover how Markforged printers can transform your business.

More Than Just a Pretty Wheel

For almost 30 years, the Schardt brothers have designed and built wheels that maintain the strength, safety, and performance requirements for sports car racing. Utilizing their own experience, passion for motorsports, and tools like SOLIDWORKS Simulation, they have developed an impressive line of wheels that the motorsports community (and companies like Ford and Chevrolet) has come to rely on.

Follow Forgeline’s path to motorsports excellence. Find out how SOLIDWORKS Simulation can transform your designs.

Markforged FX10

Create exceptionally strong, metal and composite parts for demanding automotive applications.

Formlabs Fuse 1 +30W

Achieve precise prototypes and small production runs using advanced SLS printing technology.

Artec 3D Scanners

Reverse engineer complex automotive aftermarket parts when original CAD data is unavailable.

Hexagon 3D Scanners

Conduct detailed, high-resolution inspections to ensure quality and precision.

DyeMansion Powershot S

Give components professional finishes for enhanced aesthetics and functionality.

Agile Hardware Solutions

Leverage the latest in hardware innovation to bring your designs to life efficiently and effectively.

North American Manufacturing,

On Demand

Get high-performance, high-quality parts, fast with local, North American manufacturing services. Manufacturing-as-a-service (Maas) providers offer 3D printing, 3D scanning, and traditional manufacturing services so you can optimize costs, speed up production, and manufacture your parts and prototypes sustainably and locally.

With MaaS, you can:

- Optimize manufacturing workflows

- Lower operational costs

- Scale your production to meet demand

With Hawk Ridge Systems, Success Integration Excellence Expertise Efficiency Reliability Innovation Precision Comes Standard

140+

Engineers on Staff

430+

Combined Certifications

25+

Years in Business

98%

Customer Satisfaction Rate

Related Resources

A Practical Guide to Success: Automotive Supplier’s User Manual

Download User Manual

OEMs + Automotive Suppliers: How Collaborative Design Transforms Challenges into Competitive Edges

Read the Blog

Engineering Agility: The Always-On Competitive Advantage for Automotive Suppliers

Read the Blog