We’re sharing three real-world examples from shops producing parts for automotive covering how they utilized CAMWorks to increase efficiency, along with actionable tips to implement in YOUR shop.

No big deal, but these companies achieved faster production, reduced costs, and created higher output. Keep reading to see how you can apply similar strategies to your operations.

Roush Industries: Reduced Machining Time from 45 Minutes to 15 Minutes

Roush Industries makes precision-engineered prototypes and components, including cylinder heads for racing and prototype engines for automotive. Fun fact: A division of their company also does technical support and design and engineering for attractions at major theme parks.

They boosted throughput with CAMWorks automation, cutting complex cylinder head porting from 45 minutes to 12–15 minutes. This enabled 3–4 times more parts per hour, freeing capacity for complex work and lowering per-part costs for competitive bidding.

Products: CAMWorks, Mazak Integrex e-420 five-axis mill-turn center, SOLIDWORKS.

ROI/Results: Reduced machining times by up to 73% (45 to 12-15 minutes), slashed programming time via Automatic Feature Recognition (AFR) and Technology Database (TechDB), minimized handwork, and boosted productivity in high-precision engine enhancements.

How Roush Industries Utilizes CAMWorks

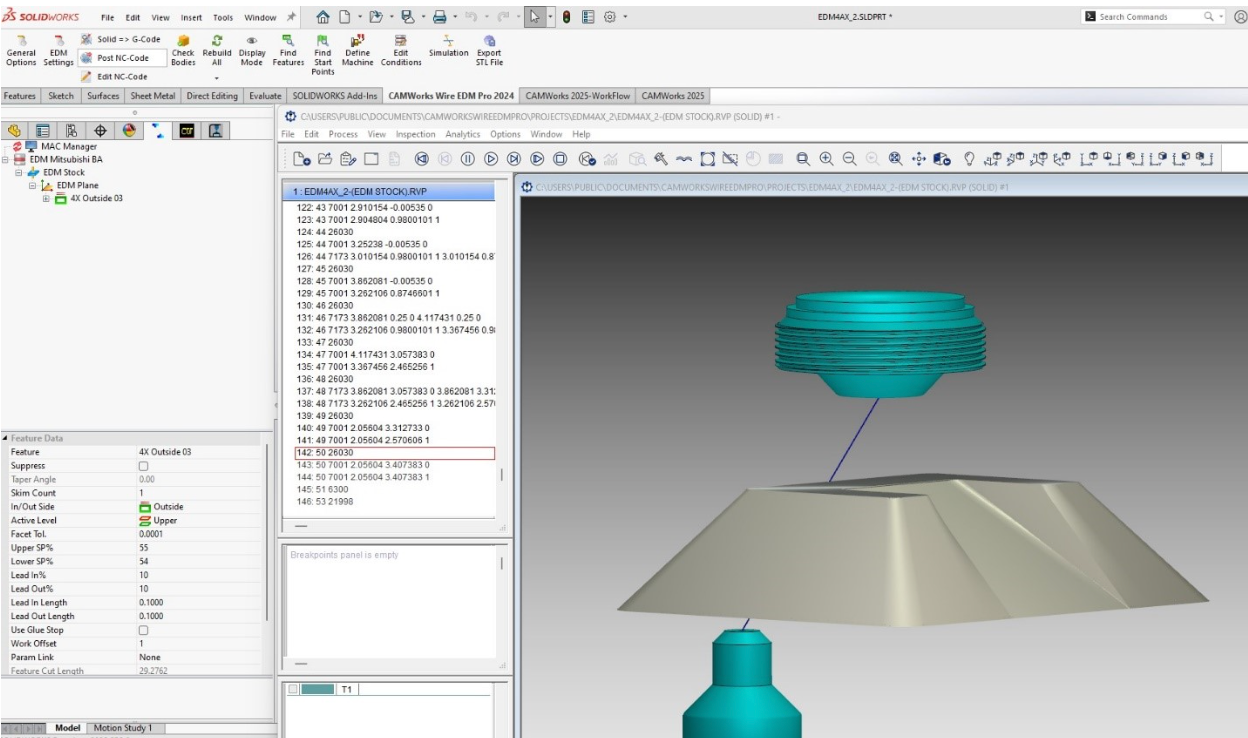

Roush adopted CAMWorks to optimize complex cylinder head porting on a five-axis Mazak Integrex, automating toolpath generation for multi-axis milling and turning. They switched from a legacy CAM system to CAMWorks. They use AFR for prismatic features in SOLIDWORKS models and TechDB for storing machining operations, feeds, speeds, and tools. They generated 3- to 5-axis toolpaths in background threads for multitasking and programmed milling and turning as unified (or merged operations) to reduce setups.

Most Useful Tip:

Customize TechDB with recurring paths, tools, feeds, and speeds for faster complex five-axis cuts like ports.

Use It in Your Own Shop:

- Evaluate CAM for multi-axis milling/turning, switch to solids-based systems with strong AFR and TechDB if needed.

- Customize TechDB early with proven tools, feeds, speeds, and paths for common jobs (Example: cylinder head contours).

- Generate complex toolpaths in background threads to avoid interruptions.

- Program mill-turn jobs separately, prove out, then merge to cut setups and cycle time.

- Buy multiple CAM seats for variable workloads to prevent bottlenecks.

- Collaborate with your value-added reseller for machine-specific postprocessors.

Ringbrothers: 15% Increase in Parts Produced with Same-Day Machining

Ringbrothers crafts high-end muscle car builds and custom automotive parts. The parts they make include billet aluminum car parts, exterior styling components, and carbon body parts for classics like Mustangs, Camaros, Chevelles, Challengers, and Monte Carlos.

A 15–20% expansion added dozens of SKUs without proportional overhead growth.

This boosted scalable catalog revenue and high-margin custom builds, enabling faster projects and creative freedom in a small shop serving international clients — proving SOLIDWORKS-integrated CAM excels in low-volume, high-creativity settings.

Products: CAMWorks 3D CNC machining software, CAMWorks VoluMill high-speed module, SOLIDWORKS, Haas VF3 3-Axis CNC Vertical Machining Center (15,000-rpm spindle, 21+1 tool changer).

ROI/Results: They accelerated R&D, increased parts by 15-20%, hit 600 IPM feed rates, enabled same-day design-machining-installation, and used TechDB for efficient recognition and texturing.

How Ringbrothers Utilizes CAMWorks

Ringbrothers integrated CAMWorks VoluMill with SOLIDWORKS and Haas VF3 for R&D, prototyping, and low-volume production of unique billet aluminum and styling parts.

They integrated CAMWorks in SOLIDWORKS for full associativity, used VoluMill for high-speed roughing (80% chip removal at up to 600 IPM). They also utilized automatic feature recognition to identify geometries for efficient toolpaths and built custom TechDB for tools, strategies, and features like contours and textures.

Most Useful Tip:

Quick TechDB investment saves time in programming and reuse.

Use It in Your Own Shop:

- Integrate CAM in SOLIDWORKS for associativity and auto-updates on model changes.

- Use high-speed roughing like VoluMill for bulk material removal (target 80% chips, up to 600 IPM).

- Spend 30-60 seconds per part on AFR and custom TechDB for tools/strategies — ideal for low-volume, high-SKU ops.

- Use CAM library for creative/recurring elements to iterate quickly.

Anchor Danly: 15% Increase in Spindle Uptime

Anchor Danly produces tool, die, and mold components for many customers including major automotive OEMs like GM, Ford, Honda, and Tesla. They produce die sets, components (pins, bushings, springs, punches, wear/guide parts), premium steel plates, automation bases, and custom fabrications for tools/dies/molds, very large, engineered die sets, and stamping components for automotive production.

With CAMWorks, they gained 15–20% spindle uptime (the time a CNC spindle actively cuts), converting machine time to output without extra capital. Ryan Wozniak called it “the product I’ve been looking for during the past 10 years” to keep spindles running.

Products: CAMWorks, SOLIDWORKS.

ROI/Results: They increased spindle uptime 15-20%, improved quoting via simulations, reduced scrap/rework, eliminated paper costs, and enhanced throughput with operator confidence.

How Anchor Danly Utilizes CAMWorks

They implemented CAMWorks to streamline precision pins, bushings, and die sets via SOLIDWORKS integration, feature recognition, and digital shop access. They replaced inconsistent SmartCAM G-code with CAMWorks’ AFR and TechDB for reusable strategies, tools, and sub-routines across complex components.

Their SOLIDWORKS integration auto-propagated model changes to toolpaths and ShopFloor digitized floors with monitors for model interrogation, measurements, cross-sections, and simulations — eliminating paper setups. Their estimators used simulations for accurate quotes, including variables like tool changes. This boosted operator confidence, reduced errors, and minimized downtime for high-precision work.

Most Useful Tip:

Utilize hop monitors for 3D viewing, measuring, cross-sectioning, and use simulation to boost understanding and increase uptime.

Use It in Your Own Shop:

- Replace legacy CAM with feature-based systems and reusable TechDB for standardized results.

- Go paperless: Install monitors and shop software for direct model/toolpath access, reducing errors.

- Train operators on model interrogation for confidence and less downtime.

- Base quotes on full simulations plus real factors (e.g., tool changes) for accuracy.

- Ensure CAD/CAM integration for auto-toolpath updates on revisions.

- Start with AFR for common parts (e.g., pins), build TechDB for complex jobs.

Add Automation Where You Can to Future-Proof Your Automotive Shop

For SOLIDWORKS-based automotive shops, CAMWorks outperforms alternatives like Mastercam or Fusion 360 by delivering fast, error-free, high-output results. That’s why brands like Roush, Ringbrothers, and Anchor Danly are using CAMWorks instead of Mastercam or Fusion 360 to transform their workflows. For transparency, it’s worth noting some shops also utilize more than one CAM software for specific types of workflows and jobs. If you’re looking for CAMWorks specifically, however, you are in the right place.

Check out our resources for CAMWorks:

- Customer Story Speedway Motorsports

- CAMWorks Handy Features You Should Know

- The Top Features in CAMWORKS for Accelerating Machining

- More Really Important CAMWorks features for Accelerating Machining

- Key Function of Knowledge-Based Machining in CAMWorks Video

- Get the Right CAMWorks Modules Video Guide

- Top Add-Ons for CAMWorks

CAMWorks Education & Training Links

- Learning CAMWorks as a New User

- Solving the Top 3 Issues in Shop Comms with CAMWorks

- CAMWorks Multi-Task Mill-Turn Course

- CAMWorks 3 Axis Mill Course

- CAMWorks Multi-Axis (4 and 5 Axis) Mill Course

- How to Program Live Tooling Lathes in CAMWorks

- Writing Post Processors with CAMWorks

Aside from CAMWorks, there are many other ways to increase productivity and optimize the shop floor, and we put them all in this guide for you. Check out our new guide on how to Future Proof the Automotive Factory Floor or get in touch.