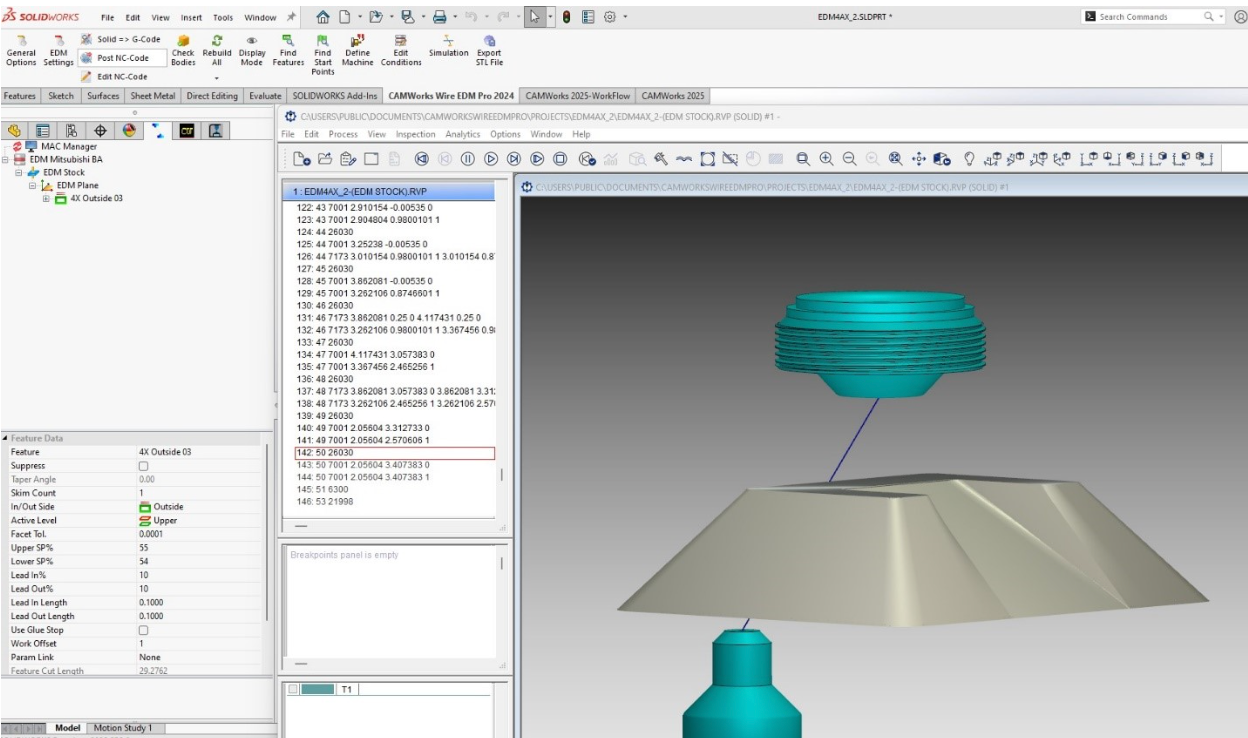

CAMWorks has new 2024 options and additional functionalities to make parts faster, easier and better. We’ll discuss six of those changes as they relate to specific modules.

1. Adding Machine Aware Programming to Mill-Turn

Mill-Turn remains a significant area of emphasis for the past few CAMWorks updates. The most visible change in this environment — though it’s available in other modules too — is the option to add Machine Aware Programming.

This first release of Machine Aware Programming allows the user to bring their machine’s digital twin into the CAM programming environment. Anyone programming complex parts in a tight Mill-Turn work envelope knows there are ample opportunities for interference.

CAMWorks’ Machine Aware Programming provides the ability to see potential interference conditions between tools, holders, tooling blocks, turrets, spindles and sub-spindles, as well as the sheet metal housing of the machine.

When you can graphically display your machine’s digital twin, it instills more confidence and reduces dry-run and prove-out delays while giving you, as the CNC programmer, a tool to avoid costly crashes. Eliminating one crash could more than offset the cost of creating your machine’s digital twin.

To support Machine Aware Programming, CAMWorks adds the ability to store turn tooling blocks in the TechDB. Models can be imported from tooling block manufacturers or created by the user.

2. Introducing VoluTurn: A New High-Performance Rough Toolpath Option

VoluTurn is a new high-performance rough toolpath option in the turn and mill-turn environment. It’s written by the same people who invented the groundbreaking improvements to rough milling in VoluMill.

VoluTurn is easier on your machine tool, reduces machine loads, and increases and provides more predictable tool life while including collision avoidance between insert, holder, part and stock.

Milling improvements range from 2.5-axis milling to 5-axis simultaneous milling. In 2.5-axis milling, new tooling descriptions include the ability to specify upper and lower drive points for keyway, dovetail, boring and user-defined tools. This milling enhancement gives the user more control when machining critical part features.

The changes in 2.5-axis VoluMill roughing allow you to avoid faces during toolpath calculation and suppress top and bottom fillets. This additional enhancement provides easier toolpath creation with greater control.

3. Condensing or Separating Previous Split Holes

In CAMWorks, the ability to recognize split holes — separate colinear holes sharing the same diameter and center location at different depths of the part — has been available for a long time.

In past versions, the ability was limited to only automatic detection. You cannot change the results after you run Automatic Feature Recognition (AFR).

Now, in 2024, the user can interactively condense or separate previously condensed split holes. Included with this new ability, CAMWorks knows and displays the number of condensed cylinders, the cylinders’ height and depth, and the distance between them.

4. Achieving Faster Machines Times & Safer Operations with Optimized Pecking

CAMWorks is known for accelerating CNC programming and machining. Piggybacking on the new functionality in condensed split holes, CAMWorks 2024 offers an Optimized Pecking option that eliminates peck moves in the air gap between material segments for faster machine times and safer operation.

5. Adding Bottom to Top Option to Contour Mill Operations

Contour Mill Operations gets a new “Bottom to top” option, which allows the user to start cutting from the bottom of the feature and move higher in Z on successive passes. This new option is especially helpful with tapered features and keyway slots.

6. Bringing Additional Control with Multiaxis Milling

The CAMWorks Multiaxis Mill module brings additional control to 4- and 5-axis simultaneous milling. A new Tilt Tool through the Contact Point option allows users to select a bottom surface on their parts and then tilt relative to that surface during machining.

Users can also employ different contact point strategies along the tool axes to position the tool in more optimum cutting orientations. These contact point options include specifying the height of the contact point and the distance along the profile of the contact point.

The Mutliaxis module also gets new Tool Axis Smoothing functionality. This option in 5-axis simultaneous milling allows programmers to edit tool lead angles and side tilt angles. Significant surface finish improvements have been reported with this new Smoothing option.

The Final Note

Those are the new updates for specific modules! If you want more information on how to use these module features or explore new options, take a look at “What’s New in CAMWorks 2024” in your software help files.

Contact us if you have any questions or are looking for product demos, training or consulting.