Formlabs SLS 3D Printers

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

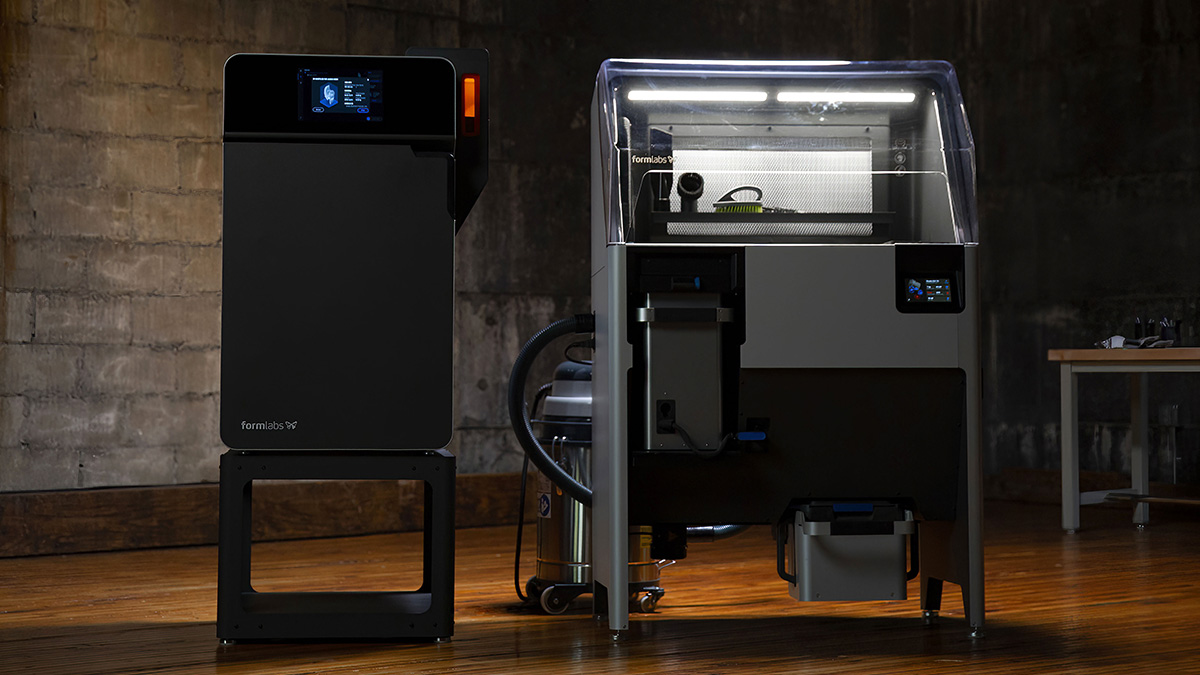

Reinvent Your Prototyping and Production Process With Formlabs SLS 3D Printers

With the Fuse 1, you can print parts in a wide range of materials, including Nylon PA12, TPU 95A, and Nylon PA11. This versatility means that you can create parts with unique mechanical properties to match your specific application needs.

Whether you are prototyping or producing final parts, the Fuse 1 can significantly reduce lead times and costs associated with traditional manufacturing processes. By leveraging the power of SLS technology, the Fuse 1 can deliver exceptional parts with fine details, strong structures, and excellent surface finishes. The Formlabs Fuse 1 is an essential tool for manufacturers looking to optimize their production process and deliver high-quality parts in a cost-effective manner.

Technical Specifications

|

Features

|

FUSE 1

|

FUSE 1+ 30W

|

|---|---|---|

|

Build volume

|

165 x 165 x 300 mm (X,Y,Z) 6.5 × 6.5 × 11.8 in

|

165 x 165 x 300 mm (X,Y,Z) 6.5 × 6.5 × 11.8 in

|

|

Layer thicknesses

|

110 microns .004 in

|

110 microns .004 in

|

|

Build Speed

|

0.3 liter per hour

|

0.5 liter per hour

|

|

Laser Spot Size (FWHM)

|

200 microns .0097 in

|

247 microns .0097 in

|

|

Printer Dimensions

|

64.5 × 68.5 × 107 cm (X,Y,Z) 25.4 x 27.0 x 42.0 in

|

64.5 × 68.5 × 107 cm (X,Y,Z) 25.4 x 27.0 x 42.0 in

|

|

Weight of the machine

|

114 kg/ 251.3 lbs

|

120 kg/ 265 lb

|

|

Power requirements

|

EU: 230 VAC, 7.5 A (dedicated circuit) US: 120 VAC, 15 A (dedicated circuit)

|

EU: 230 VAC, 7.5 A (dedicated circuit) US: 120 VAC, 15 A (dedicated circuit)

|

A Premier Industrial Design Studio Leverages Formlabs

Vital Auto, a top-tier industrial design studio specializing in automotive design, serves major clients like Volvo, Nissan, McLaren, and Lotus.

They utilize Formlabs Form 3L SLA printers and Fuse 1 SLS printers for high-fidelity prototypes and end-use parts. Their materials range from Elastic 80A Resin for prototype door seals to Nylon 12 for rugged components like air ducts, all crafted with precision and expertise.

Formlabs Resources

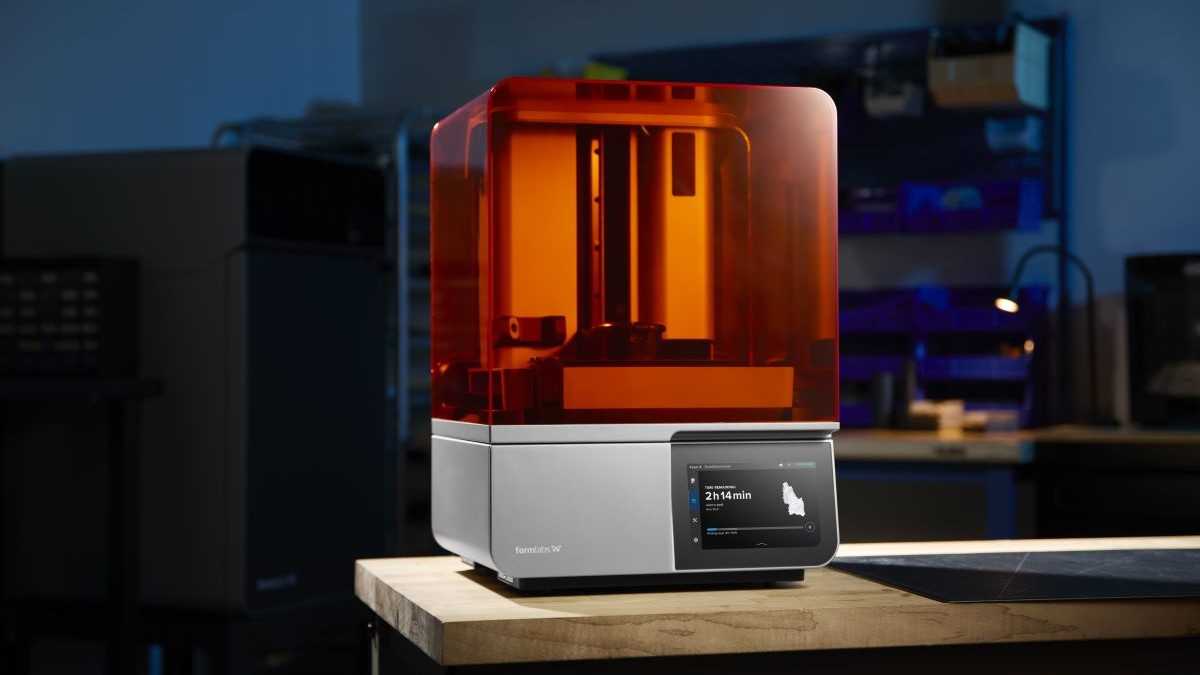

Formlabs Is Here! SLA and SLS Printers

Read Article

MedTech Additive Manufacturing in Space

Read Article

Speed Up Medical Device PLM Processes

Read ArticleFrequently Asked Questions

Formlabs offers different models of SLS printers, each with its own maximum build volume. Typically, these printers provide ample space for producing parts of varying sizes, accommodating projects ranging from small prototypes to larger-scale production components.

Formlabs SLS printers are renowned for their high precision and accuracy. With advanced laser sintering technology and precise control systems, these printers can achieve fine details and tight tolerances, ensuring consistent and reliable results for complex geometries and intricate designs.

While Formlabs SLS printers produce high-quality prints straight from the build chamber, some post-processing steps may be necessary depending on the desired finish and application. Common post-processing techniques include sanding, polishing, dyeing, or applying surface treatments to enhance aesthetics and functional properties of the printed parts.