SCANOLOGY

Precision Meets Portability

Discover SCANOLOGY’s innovative handheld 3D scanning solutions.

Every Detail, Every Time

SCANOLOGY offers a suite of handheld 3D laser scanners designed for precision, portability, and versatility. Whether you’re capturing intricate details or scanning large objects, SCANOLOGY’s blue laser technology ensures accurate results across various surfaces and environments.

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

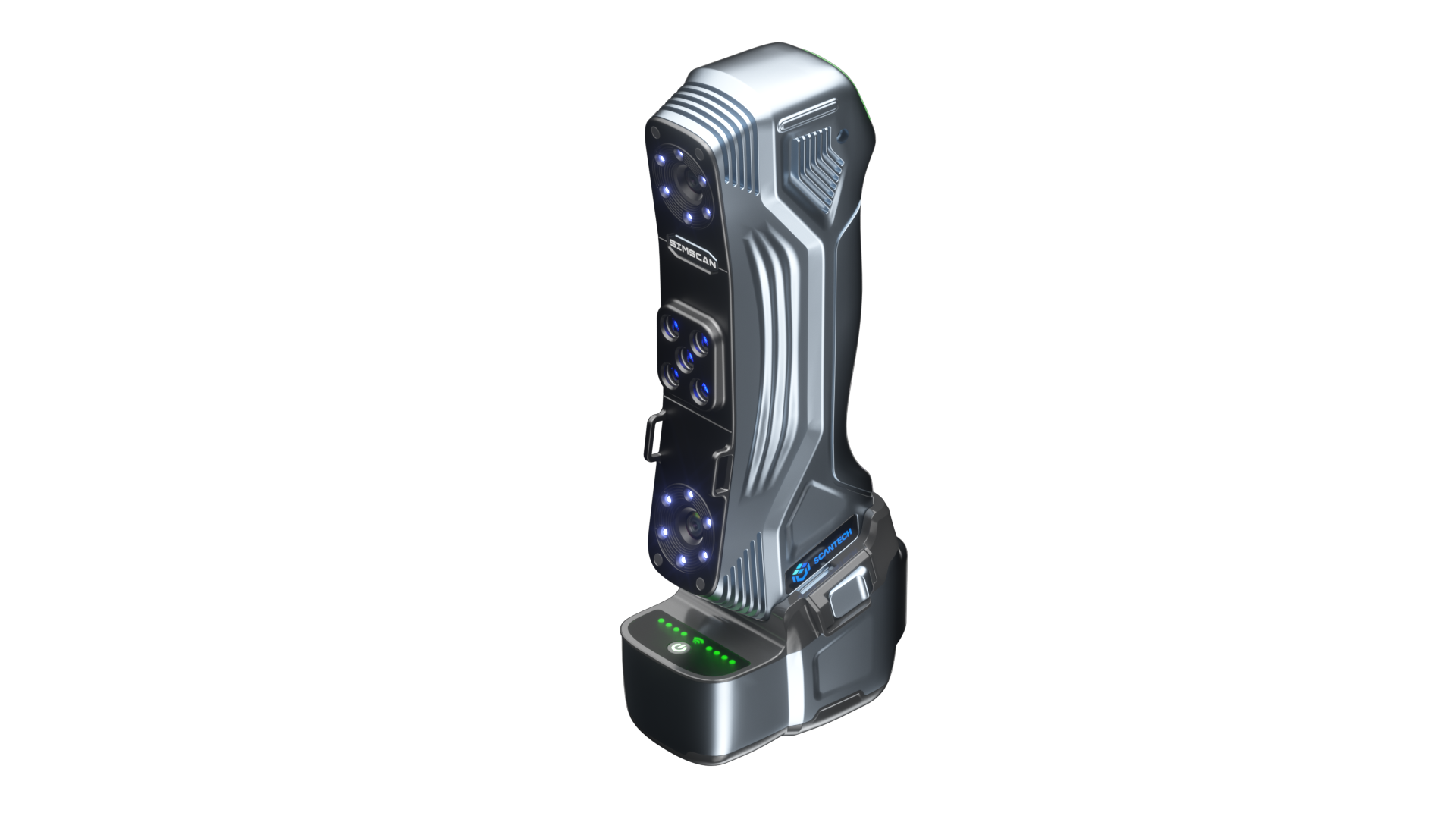

SIMSCAN Series

Compact and lightweight, the SIMSCAN series delivers metrology-grade accuracy with fail-safe target tracking. Ideal for scanning tight spaces and complex geometries.

Key Features:

- Blue laser technology for high-resolution scanning

- Wireless capabilities for enhanced mobility

- Mesh resolution up to 0.02mm

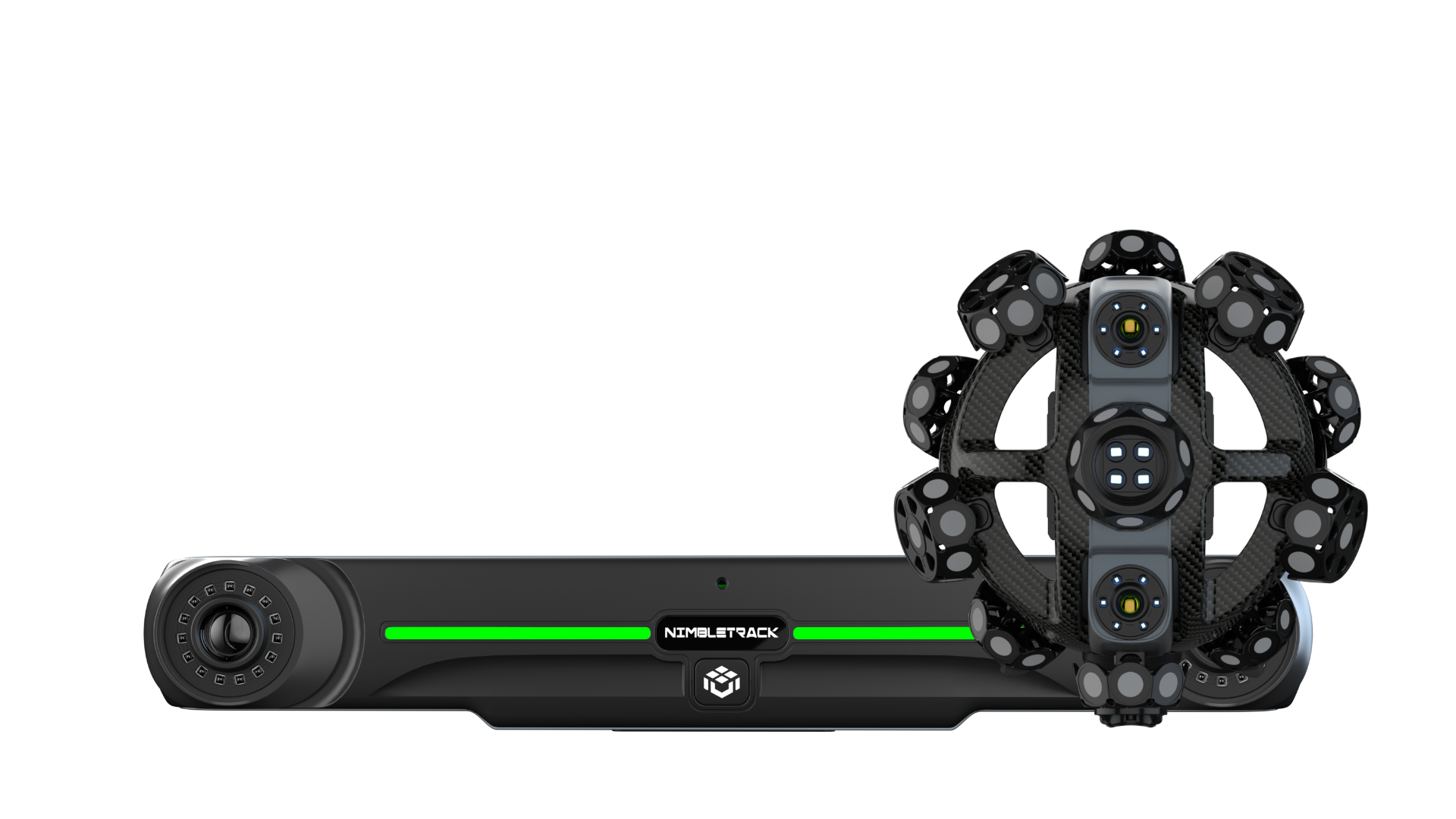

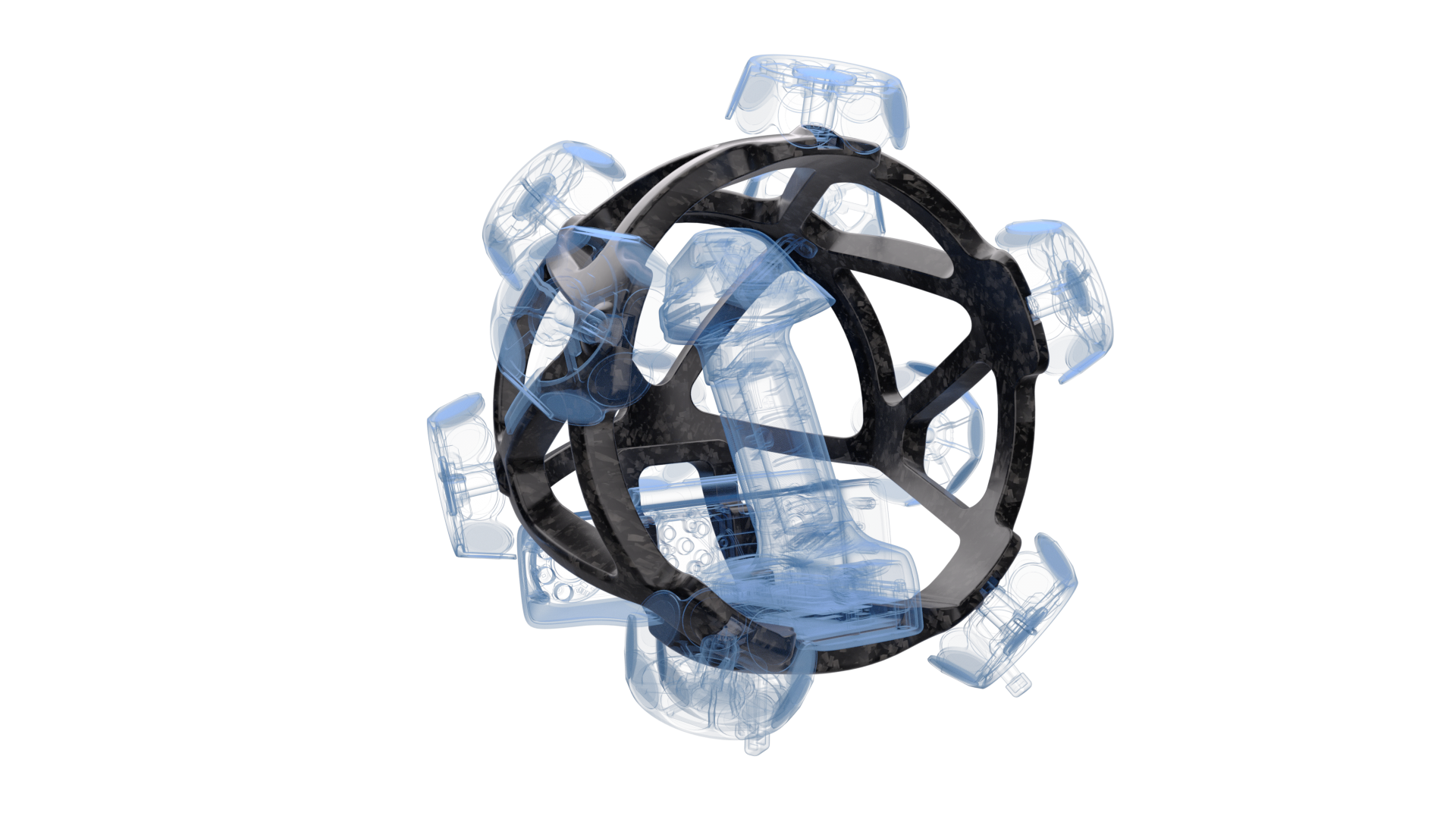

NimbleTrack System

Combining a compact optical tracker with a handheld scanner, NimbleTrack offers targetless scanning and optional touch probe integration for mixed inspection methods.

Key Features:

- Optical tracking eliminates the need for targets

- Portable design fits into a single hard case

- Mesh resolution up to 0.02mm

TrackScan-Sharp S

Designed for scanning large objects, the TrackScan-Sharp S utilizes a full-size optical tracker and 99 blue laser lines for rapid, targetless scanning over expansive areas.

Key Features:

- Scanning range up to 8.5 meters

- Volumetric accuracy up to 0.048mm

- Optional wireless touch probe for versatile inspections

KSCAN-X

Take On the Biggest Jobs with Confidence. The KSCAN-X handheld blue laser scanner lets you cover massive parts quickly and confidently — even on the biggest jobs.

Key Features:

- 0.075mm with large distance scanning

- Up to 180 FPS capture speedFfield of view up to 1.8×2.6 meters

Technology That Transforms

Cutting-edge scanner technology combines precision, mobility, and versatility to revolutionize how you capture and analyze 3D data. With blue laser accuracy, wireless freedom, and targetless scanning capabilities, SCANOLOGY delivers professional-grade results without the professional-grade complexity.

Blue Laser Technology

Ensures high-resolution scanning on challenging surfaces like polished metals.

Wireless Operation

Enhances mobility and ease of use in various environments.

Targetless Scanning

Optical tracking systems eliminate the need for physical targets, streamlining the scanning process.

High Accuracy

Achieve mesh resolutions up to 0.02mm for detailed inspections.

Versatile Applications

Suitable for industries ranging from aerospace to manufacturing.

Technical Specifications

|

Feature

|

SIMSCAN Series

|

NimbleTrack System

|

TrackScan-Sharp S

|

|---|---|---|---|

|

Light Source

|

63 Blue Lasers

|

17 Blue Lasers

|

99 Blue Lasers

|

|

Mesh Resolution

|

Up to 0.02mm

|

Up to 0.02mm

|

Up to 0.02mm

|

|

Volumetric Accuracy

|

0.015mm + 0.035mm/m

|

0.044mm + 0.012mm/m

|

0.048mm (10.4m³) to 0.159mm (135m³)

|

|

Scanning Speed

|

6.3 million pts/s

|

4.9 million pts/s

|

4.86 million pts/s

|

|

Tracking Method

|

Target-Based

|

Optical Camera

|

Optical Camera

|

|

Weight

|

600g

|

Scanner: 1.3kg; Tracker: 2.2kg

|

Varies

|

|

Operating Temperature

|

14–104°F

|

14–104°F

|

14–104°F

|

|

Certifications

|

ISO 17025, VDI/VDE 2634

|

ISO 17025, VDI/VDE 2634

|

ISO 17025, VDI/VDE 2634

|

Frequently Asked Questions

Yes, SCANOLOGY scanners use blue laser technology, which is better at capturing shiny and reflective surfaces like machined aluminum or chrome. For transparent materials, such as glass or clear plastics, a scanning spray like AESUB is recommended to ensure accurate data capture without artifacts.

No, most SCANOLOGY scanners use optical tracking systems that eliminate the need for targets on the part. However, targets can be added in tight or obstructed areas to improve tracking or align scans across multiple sessions or scanner positions.

SCANOLOGY systems can operate wirelessly once connected to compatible scanning software. Data can be streamed in real-time, giving users complete freedom of movement. Wireless scanning is especially beneficial for hard-to-reach areas and on-site inspections.

The NimbleTrack is designed for high portability with a smaller tracking volume and compact setup—great for mobile workflows and medium-to-large parts. The TrackScan, on the other hand, supports a much larger scanning volume (up to 135 m³) and is ideal for scanning large-scale objects in a stationary or industrial environment.

Absolutely. SCANOLOGY scanners support both workflows. With metrology-grade accuracy, they’re suitable for inspection applications, and the exported mesh data can also be used for reverse engineering or integration into CAD environments.

SCANOLOGY’s scanners are typically paired with their proprietary software DefinSight, which handles everything from scan acquisition to mesh editing and export. It supports common formats compatible with most CAD, inspection, and modeling software.