What Sets SCANTECH Apart?

SCANTECH is a global provider of 3D scanning systems, tackling the unique challenges companies face when digitizing products for inspection or reverse engineering. By specializing in R&D catered towards portability, tracking, and automation their devices achieve metrology-grade certifications at an affordable price.

SCANTECH is ideal for:

- Quality Control and Inspection

- Reverse Engineering

- Finite Element Analysis

- 3D Visualization

- Accelerated Product Development

Their laser systems have helped companies that work in various fields to streamline their digitization process, specifically in fields such as aerospace, automotive, assembly machinery, and electronics which require high levels of precision and difficult scanning scenarios.

Their optical systems are also useful for those who need to scan objects without applying any materials to the surface like museums, art, medical, and security.

By putting research first SCANTECH delivers high-quality and user-friendly scanning devices that are easy to use and compact for travel. In this blog we’ll cover just a few of the scanning systems SCANTECH develops and what makes them an excellent choice for those looking to digitize parts for inspection or reverse engineering.

SCANTECH Scanner Systems: Which One is Right for You?

SCANTECH offers multiple types of scanners that cater to specific tasks or part size. If you’re scanning a small component or a large assembly, the right scanner can make the job easier and ensure you’re meeting the accuracy and detail requirements for the job.

Here are some key scanners offered by SCANTECH and their specialty:

|

Scanner |

Key Features |

Tracking Method & Field of View |

Accuracy & Resolution |

|

|

Resolution up to 0.02mm and accuracy of 0.02mm | |

|

KSCAN – X |

|

|

Resolution up to 0.1mm and accuracy of 0.03mm at medium-distances |

|

|

Resolution up to 0.02mm and accuracy up to 0.025mm using the optical tracker | |

|

|

Resolution up to 0.02mm and accuracy up to 0.025mm using the optical tracker |

Wireless Scanning and Advanced Processing

Wireless scanning makes setup and data capture easier by not having to deal with long cords potentially disturbing the scanning environment. Once the wireless modes are set up, operators can significantly speed up their preparation by installing the wireless packs to the device and begin scanning.

For scanners such as the NimbleTrack and TrackScan Sharp this can make scanning multiple objects within the optical tracker environment easier due to the ability to rapidly swap parts within the scanning space or move the tracker to new positions without worrying about physical connections to a computer to log the data.

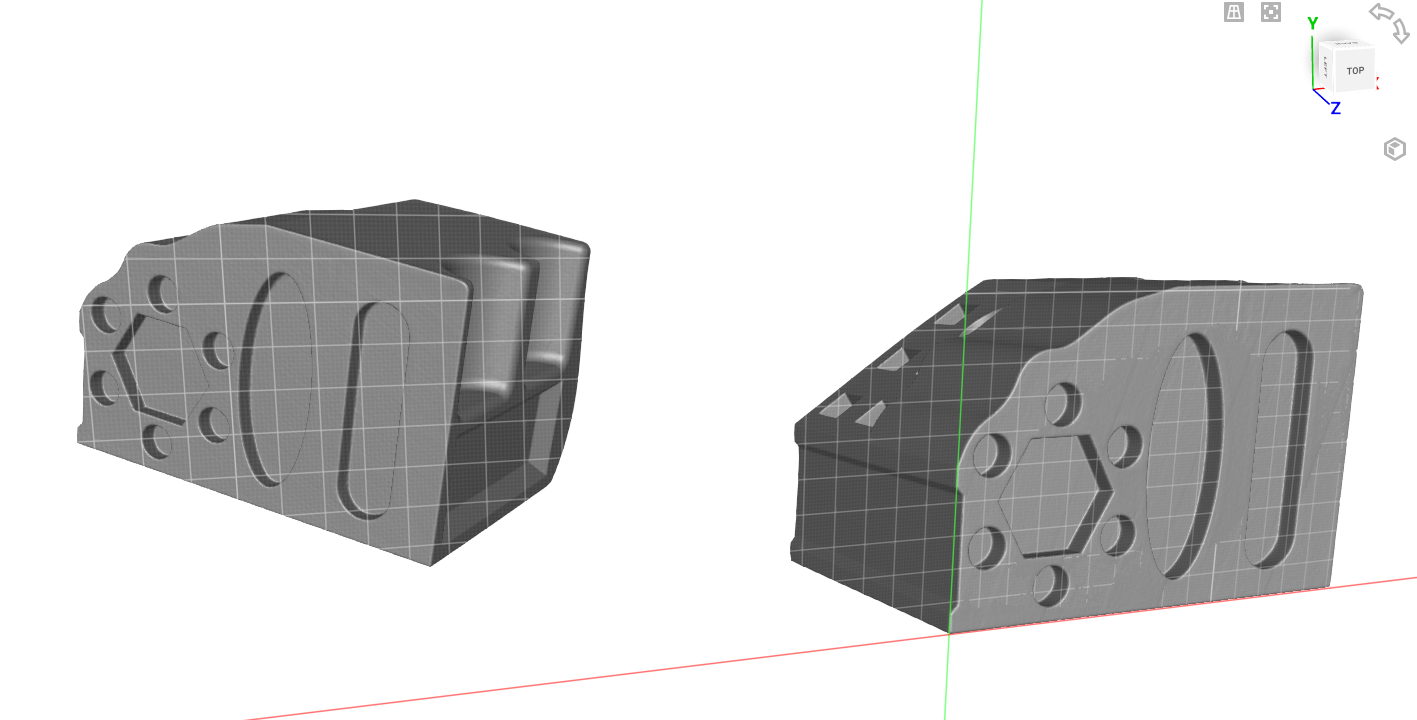

When scanning, the multi-grid blue-light lasers and various scanning modes ensure you can capture all necessary details with little to no preparation of the object’s surface. Blue-light laser technology specializes in capturing difficult-to-scan surfaces such as glossy, semi-transparent, and thin edges due to the adjustable laser frequency. If you are scanning multiple types of materials the laser can be adjusted to achieve optimal reflection so data is captured quickly and with minimal noise. And, through the use of targets on the part, around it, or on the scanner itself (like on the NimbleTrack and TrackScan) you can maintain tracking and accuracy for oversized or thin objects.

SCANTECH software and devices have noise filtering and edge-computing algorithms to ensure the data you capture has minimal outliers and misalignments. It also accounts for some environmental factors like vibrations, lighting, and temperature.

Why SCANTECH?

The SCANTECH portfolio brings metrology-grade blue-light laser scanning for small and large parts. This is perfect for those looking to scan tough surfaces (such as sharp edges and sheet metal) and thin objects with ease. Hawk Ridge Systems works to continue to provide solutions for all engineering needs by working with innovative companies. With professional, highly accurate scanners at an affordable price point, we’re confident that by working with SCANTECH we can continue to achieve this and fully cover all needs with our scanning portfolio.

Learn More about SCANTECH and Hawk Ridge Systems

These are just some of the scanners and technologies SCANTECH offers to help engineers, inspectors, and designers make high-quality digital assets for quality control, inspection, reverse engineering, and more.

SCANTECH also offers product lines for highly specific use-cases like scanning large assemblies for aerospace applications that require large sections of featureless panels to be scanned.

Interested in learning more about SCANTECH devices? Contact us or schedule a demo.