How often do you wait until you have a physical prototype in hand to start

your wire harness design? Do you see revisions to your mechanical assemblies

that force changes to your wire harnesses? Have you seen delays to product

launches due to waiting for your wire harnesses to be designed and built? If

you answered yes to any of those questions, you might want to start

integrating your wire harness design into your

SOLIDWORKS

assemblies. This can be done in several ways.

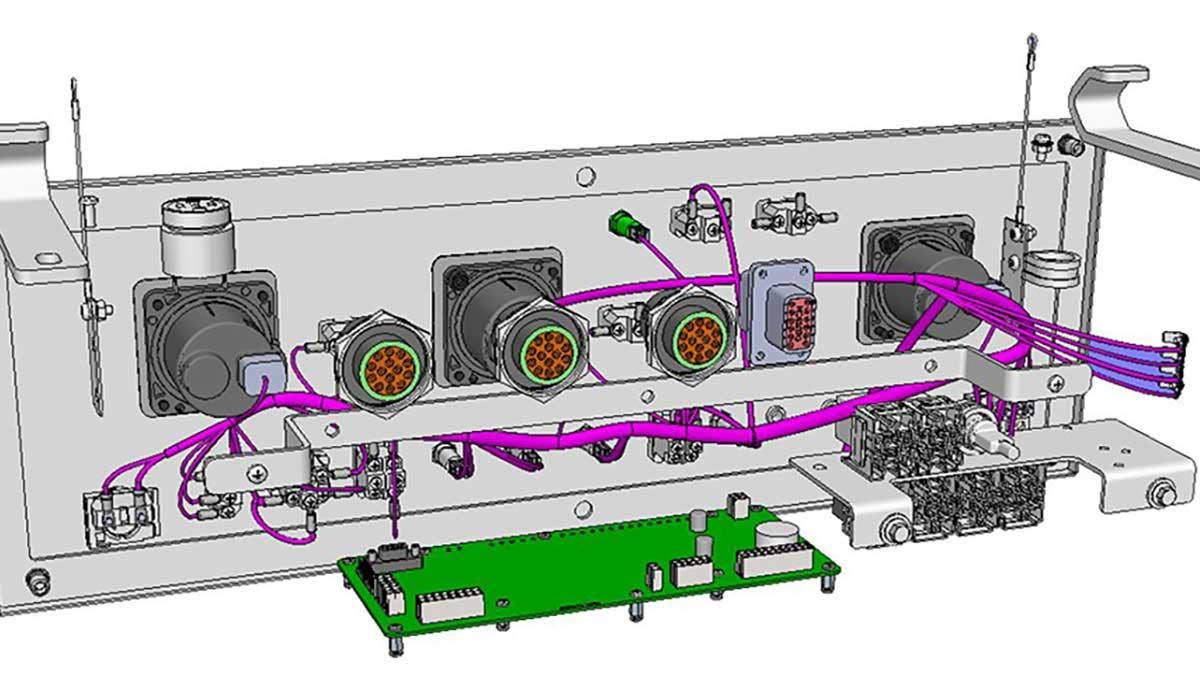

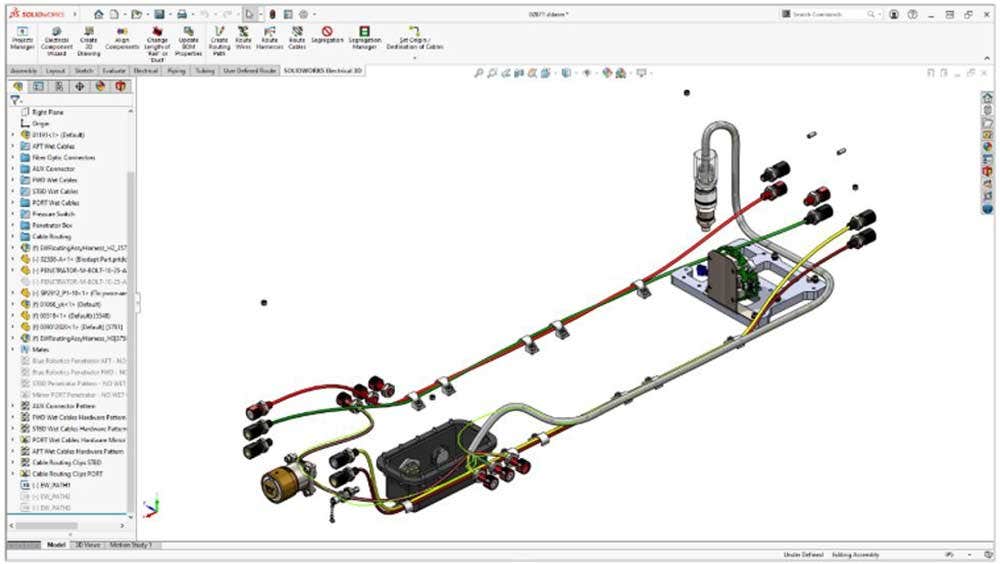

SOLIDWORKS Premium Electrical Routing

The routing tools that are part of SOLIDWORKS Premium are a great starting

point if you only need to integrate a few wire harnessing elements into your

SOLIDWORKS assemblies. It gives you the ability to design the harness on the

fly by dragging and dropping the connectors from your design library, then

define the routes with 3D sketches. The size of the harness adjusts as you add

or remove wires from the harness. Then, utilizing SOLIDWORKS Drawings, you can

detail out the flattened state of the harness. The big drawback with

SOLIDWORKS Routing is the need to build your library up with all the

connectors, wires and cables.

SOLIDWORKS Premium Electrical Routing

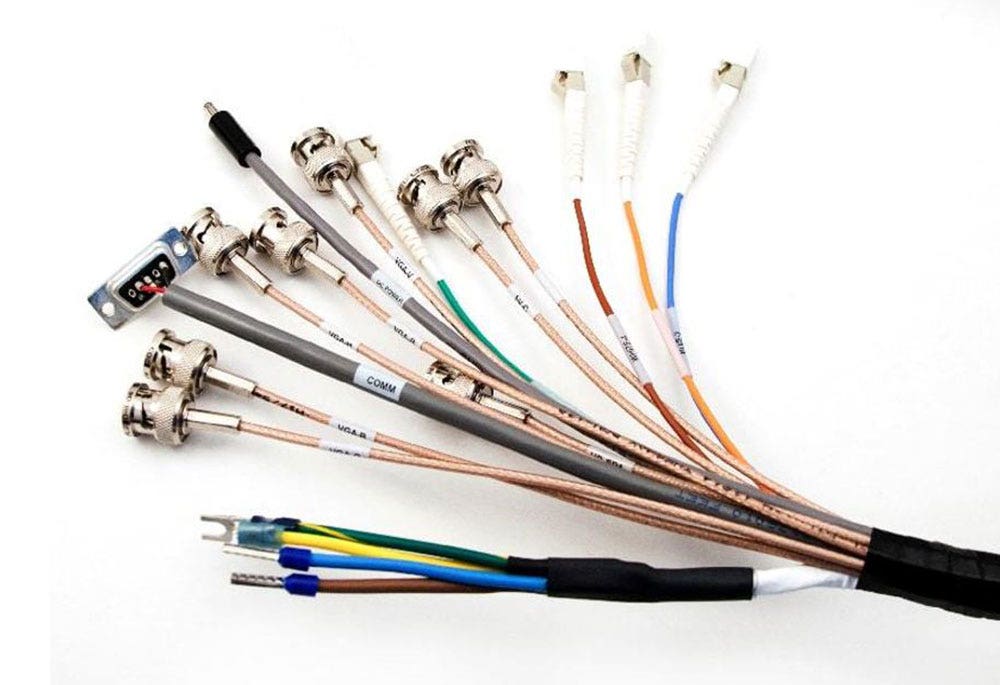

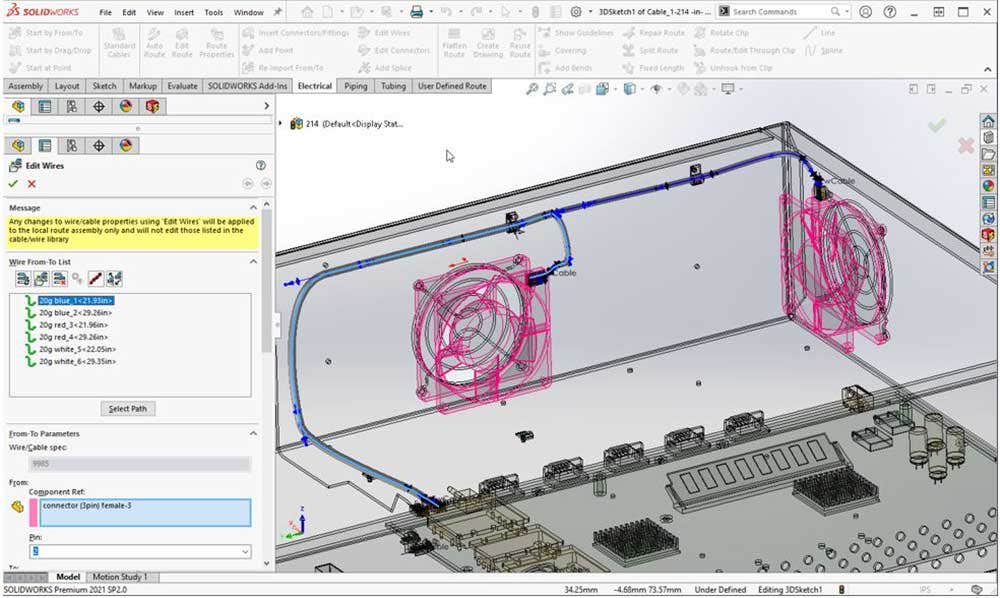

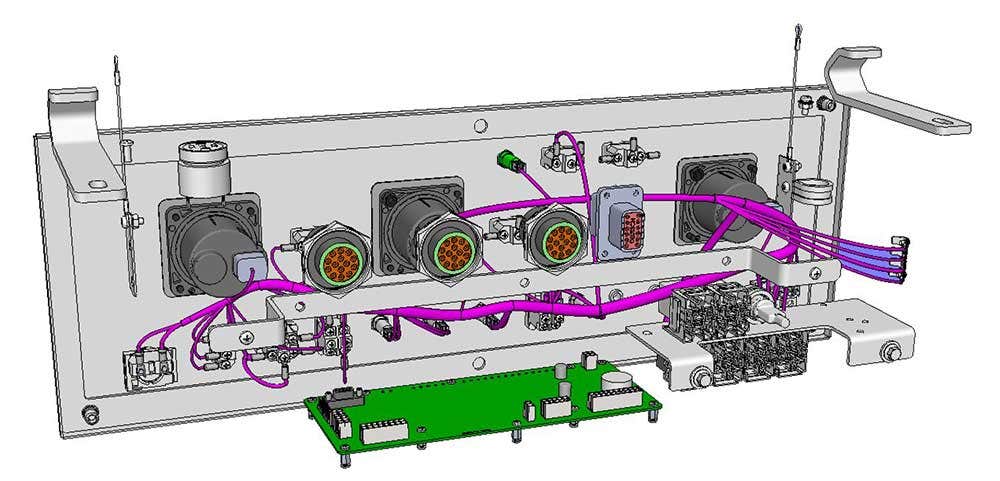

SOLIDWORKS Electrical

Another option for integrating your wire harnesses into your SOLIDWORKS

assemblies is to utilize the

SOLIDWORKS Electrical suite, consisting of

SOLIDWORKS Electrical Schematic Professional

and

SOLIDWORKS Electrical 3D. The advantage of SOLIDWORKS Electrical is that it will automate 80 percent

of the work you will do using SOLIDWORKS Routing. This is done by taking the

design requirements from the Schematic. Then, Electrical 3D will import the

information needed directly from the Schematic, eliminating the need to build

up a cable and wire library for routing. The connectors that are used are

listed on the Electrical Manager next to the design tree, eliminating the need

to search the Design Library for parts. The one drawback with this solution is

the limit to the size and shape of the harness, as you increase the number of

wires and cables in the harness and the number of branches, the flattening of

the harness can become unpredictable.

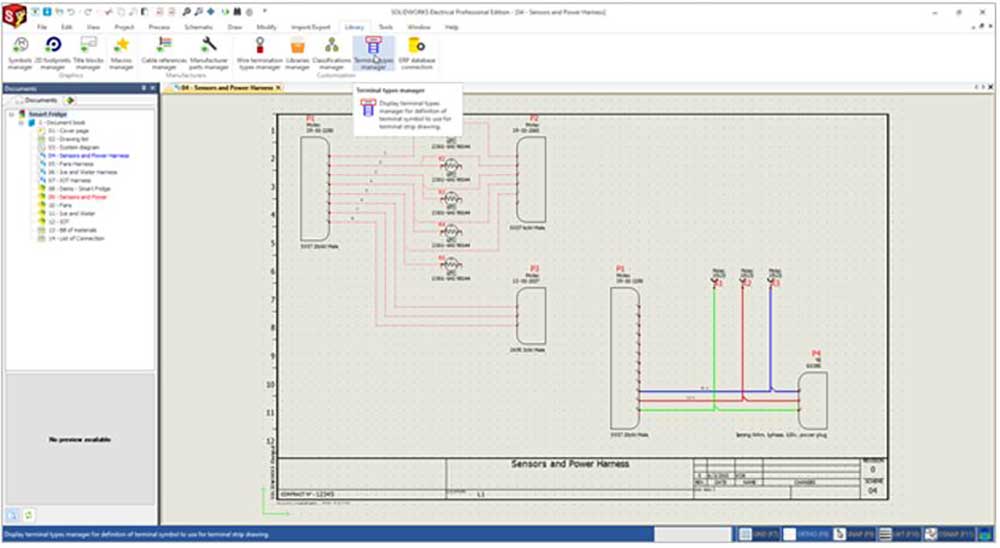

SOLIDWORKS Electrical Schematic

SOLIDWORKS Electrical 3D

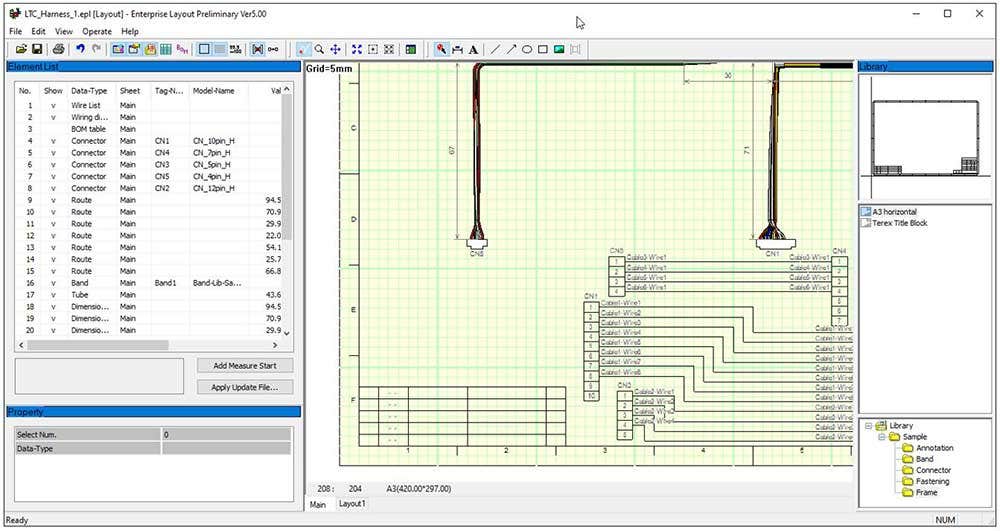

Enterprise Harness

Even with the strengths of both SOLIDWORKS Routing and SOLIDWORKS Electrical,

they both have shortcomings. This is why we added our last harness design

offering,

Enterprise Harness. Enterprise Harness from Landmark Technologies is a SOLIDWORKS partner

product that works with your SOLIDWORKS assemblies. Enterprise Harness allows

you to design your harness in a lightweight environment that is not restricted

by the strict rules of SOLIDWORKS Routing.

You can utilize a from-to list generated from a variety of tools, though we

recommend SOLIDWORKS Electrical Schematic Professional because of its powerful

backend database. Enterprise Harness is a much more robust tool for larger

harnesses, with the ability to handle a larger number of wires and branches

with ease. Enterprise Layout is the drawing and detailing tool with robust

Flattening ability helping eliminate excess work. Your completed 3D harness

shape can be exported back to your SOLIDWORKS assembly with a single push of a

button.

Enterprise Harness

Enterprise Layout

No matter your design requirements we have a solution to help speed up your

wire harness design integration into your mechanical assemblies. Visit our

website to explore

SOLIDWORKS Electrical

features, as well as other ECAD options we have offer. If you have any

questions,

contact us

at Hawk Ridge Systems. Thanks for reading!