Brandner Design, a Montana-based design firm specializing in high-end custom furniture, fireplaces, and architectural metalwork, has transformed its design process with SOLIDWORKS. Brandner Design caters to luxury residential and commercial projects, including historic restorations. Their challenge: delivering highly customized, one-off designs that bridge the gap between architects, contractors, and fabricators while maintaining precision and efficiency.

Brandner Design uses SOLIDWORKS Standard and Premium to speed up design time for custom architectural designs and builds not only for luxury clientele, but historical restoration projects, and commercial and residential construction projects.

SOLIDWORKS for Parametric Design

We sat down with Matt Keller, Brandner Design, to see how they were using SOLIDWORKS in these unique design projects. He told us that they use Both SOLIDWORKS Standard and Premium to create parametric designs that allow for endless customization. “SOLIDWORKS has helped us create a parametric design setup for different configurations… we can create something unique for every customer,” says designer Matt Keller. This flexibility ensures each project, from unique fireplace doors to cabinet hardware, becomes a centerpiece tailored to the client’s vision. Unlike AutoCAD, SOLIDWORKS provides comprehensive data management, streamlining workflows for their project-based business.

“Historically a lot of our cabinetry and furniture was designed in AutoCAD, but SOLIDWORKS just gives you so much more data on each of your parts, your assemblies, all your project information. It’s data you enter once, and you use it through the whole life of the project.” –Matt Keller, Designer at Brandner Design

In addition, Brandner Design uses:

- 3D scanners to scan existing conditions while our installers measure pre-existing elements. Brandner Design gets 360-degree panoramic views, measuring from sub floor to sub floor in the house, which can’t really be field measured

- SOLIDWORKS to create and send design specs to the field

- SolidProfessor tutorials to get new designers up to speed quickly

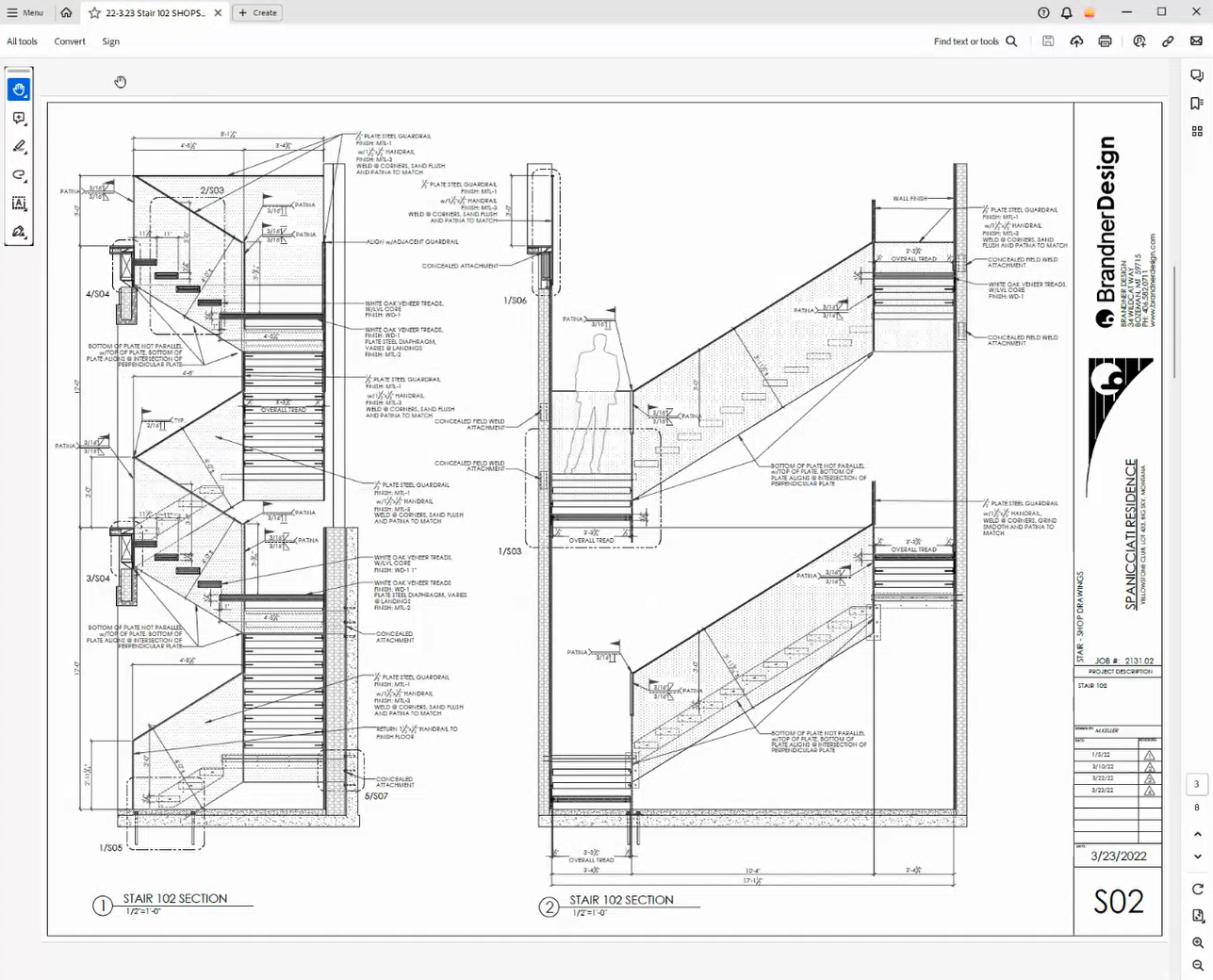

Detailed Shop Drawings

Brandner Design leverages SOLIDWORKS to bridge the gap between contractors and architects by providing PDF copies of all shop drawings which allows them to go to manufacture with all the custom specifications and information they need.

For larger projects, Brandner Design saves their models as 3D PDFs and shares them directly with the owner and contractor for final sign off — no need for file conversion or for them to have SOLIDWORKS.

Unlike a lot of architecture drawings, the drawings Brandner Design creates in SOLIDWORKS are actually the same files that will be used to manufacture and build out the designs.

SOLIDWORKS Over AutoCAD

A key problem solved is communication with stakeholders. Brandner leverages SOLIDWORKS to produce 3D PDFs and eDrawings, enabling architects and contractors to review designs without needing specialized software. “The larger projects, we’ve saved our model as a 3D PDF… they don’t need file conversion,” Keller explains.

This clarity extends to fabricators, who receive clean, manufacture-ready drawings, and installers, who benefit from precise sketches. “Our installers love when we use SOLIDWORKS because it’s apples to apples,” Keller adds.

The results are striking: workflows are faster, with projects that once took 20-30 hours now completed in as little as 12. Multibody part design and weldment features have further accelerated file management, freeing designers from complex naming systems.

Everyone at Brandner loves the user experience from SOLIDWORKS, whether it’s automated industrial machinery, architectural, cabinetry. They also have a novel use of the weldments feature in SOLIDWORKS and say that the software is only limited to the designer’s creativity and curiosity. For example, there’s a lot of opportunities for multibody parts, because it doesn’t have to be an actual weldment to those product features.

They also single out all the parts to make the file management and design go faster, making extensive use of multibody part design which has dramatically increased their speed.

Their customers don’t need 2D drawings anymore to install. In eDrawings, Brandner Design includes the sketches that they use to install to design, and each installer gets all the information they need to build.

“Everything we share with the client is what we use to manufacture.” -Matt Keller, Designer at Brandner Design

SOLIDWORKS and tutorials from SolidProfessor elevated Brandner’s ability to deliver flawless, custom designs that fit perfectly into clients’ spaces.

“Hawk Ridge Systems is responsive and supportive for any of the questions we’ve had. Set up and installation were easy. We use Hawk Ridge Systems and SolidProfessor for tutorials, especially for our new designers.” -Matt Keller, Designer at Brandner Design

More Resources

Check out SolidProfessor’s design and engineering tutorial library where you can sharpen your skills in CAD, CAM, and more. Want to see how other customers are using SOLIDWORKS? Check out our customer story library in the resource center. Interested in SOLIDWORKS? See our current deals.