Electrical Design Solutions

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

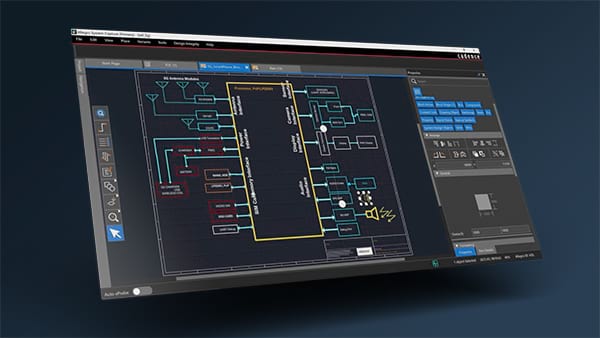

Cadence Allegro X

Scalable, intuitive, and comprehensive design platform covering schematics, PCB design, signal and power integrity analysis, and more.

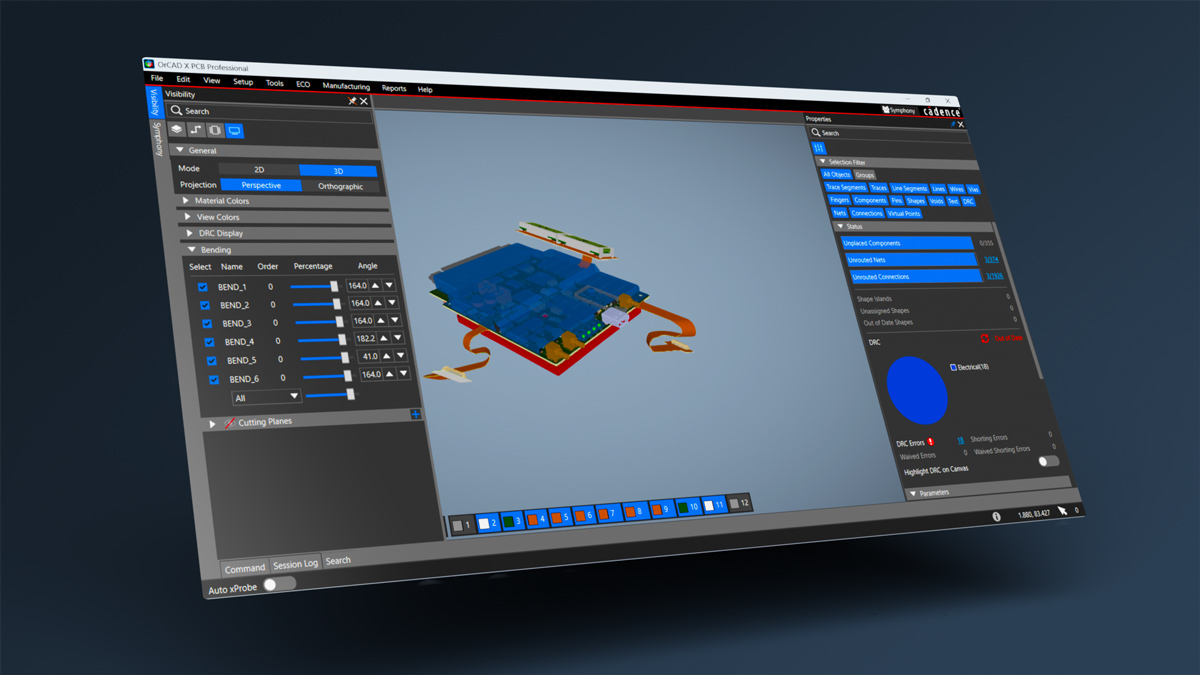

Cadence OrCAD X

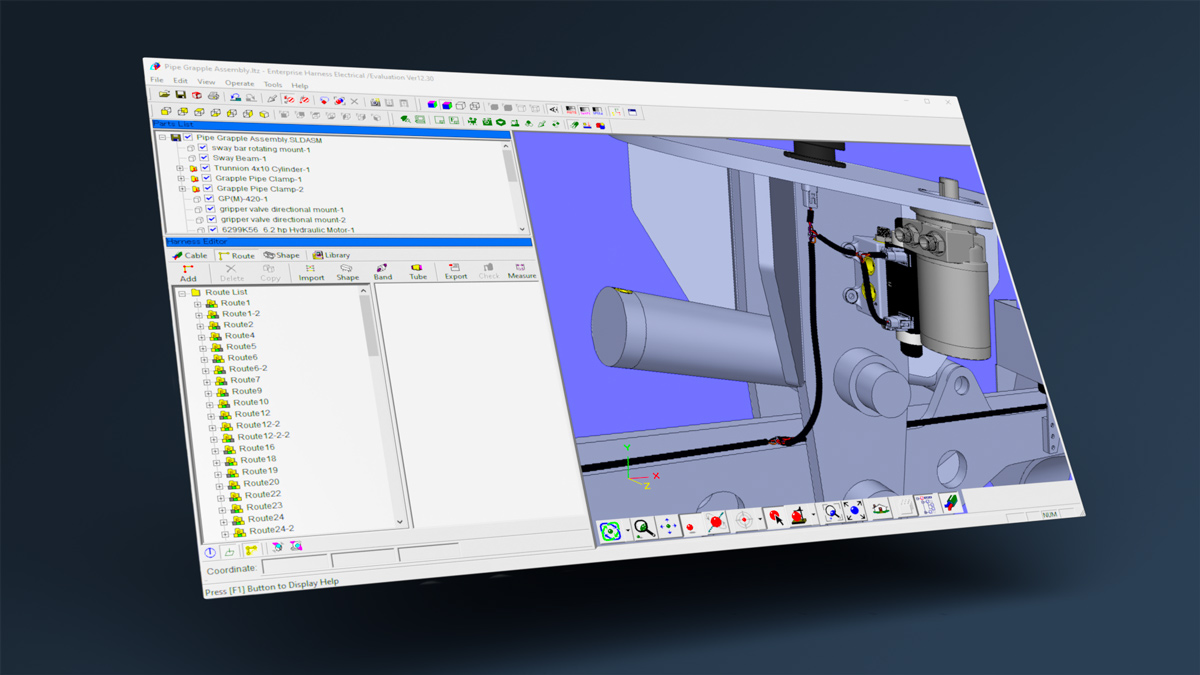

Enterprise Harness for SOLIDWORKS

Enterprise Harness is a powerful, yet lightweight tool designed to help you easily integrate your wire harness design into your SOLIDWORKS assemblies.

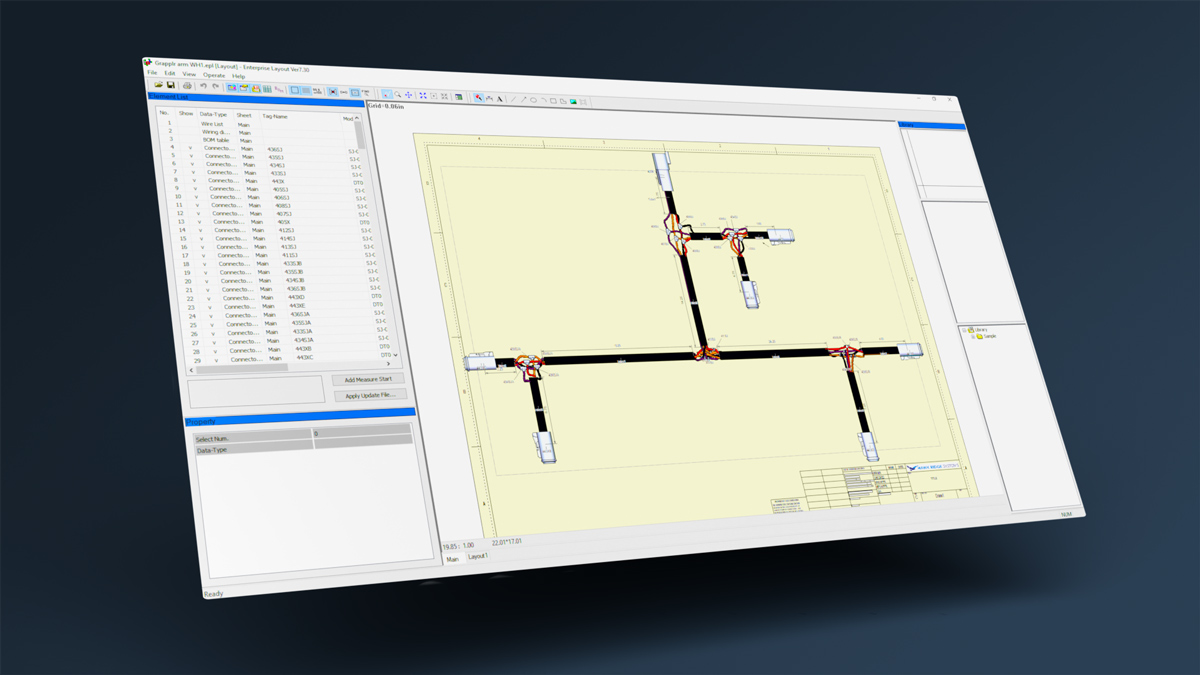

Enterprise Layout for SOLIDWORKS

Enterprise Layout quickly produces manufacturing-ready 2D layouts from your 3D harness models developed by Enterprise Harness, including wire lists, BOMs, and more.

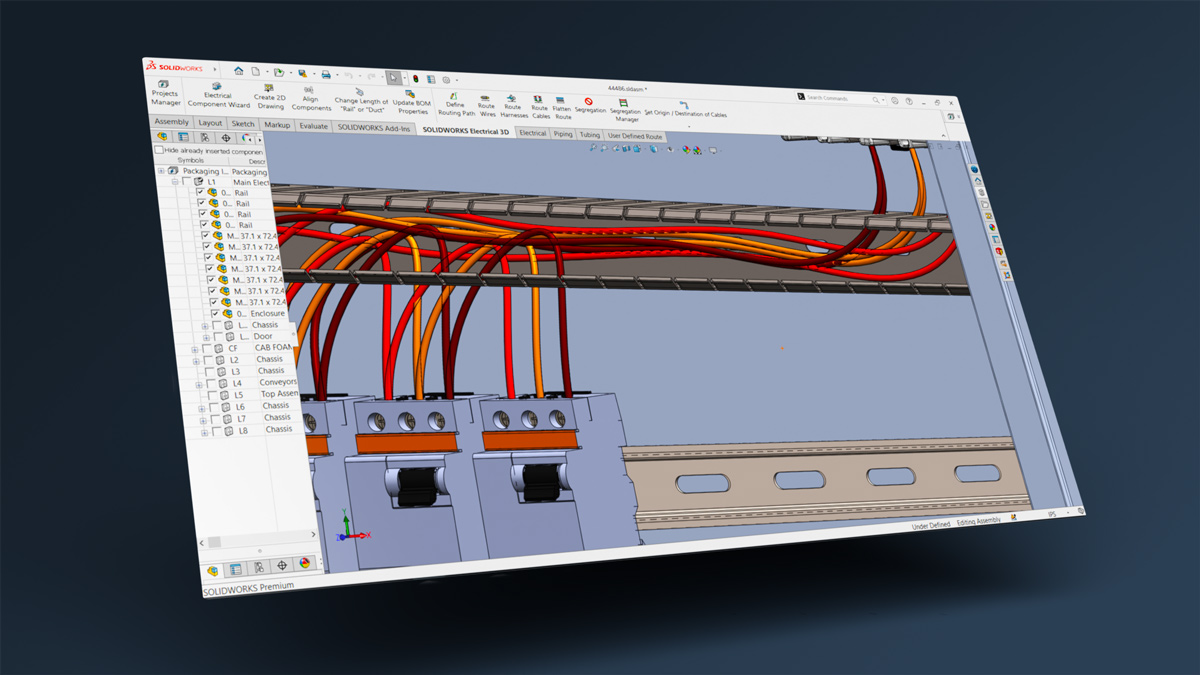

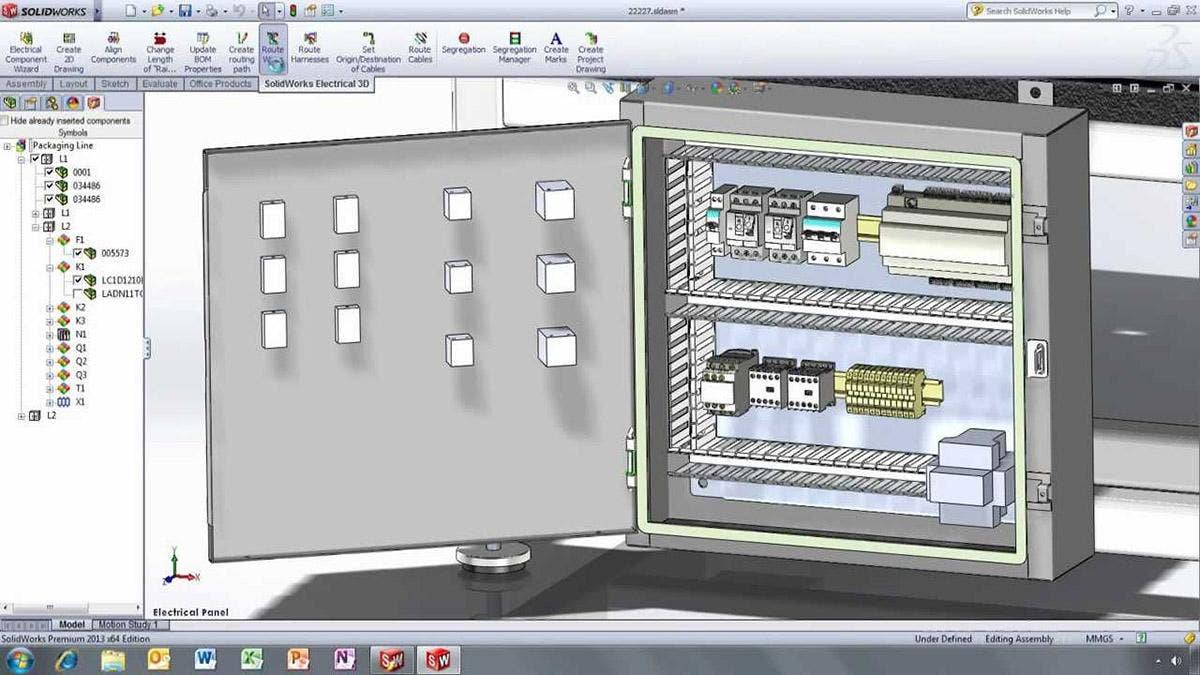

SOLIDWORKS Electrical 3D

SOLIDWORKS Electrical 3D lets you easily connect your 2D schematic to your 3D CAD model, syncing the two for easy collaboration. Simplify electrical design with SOLIDWORKS.

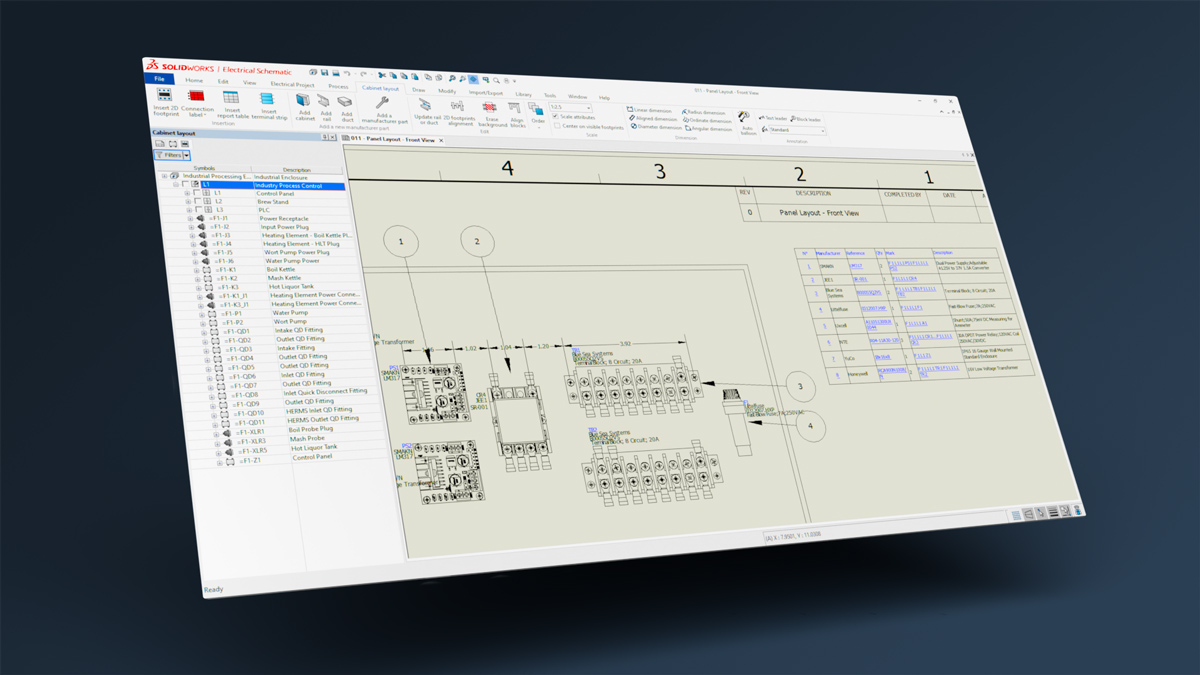

SOLIDWORKS Electrical Schematic

SOLIDWORKS Electrical Schematic is a powerful 2D electrical schematic design software that gives you the tools to collaborate better and automate tedious tasks associated with designing schematics.

Exceptional Solutions, Even Better Support

Creating the best products requires the best solutions, training and support. With a little insight into your product development process, our team of pros can point you to any tools you need (and nothing you don’t).

But it doesn’t end there. We’ll stay with you every step of the way, helping solve complex design issues, 3D printing application questions and so much more. No matter where you’re at, both in your process and geographically, we’re here.

Services & Customer Benefits

Technical Support

Our technical support team is comprised of mechanical engineers, electrical engineers, and computing specialists who provide best-in-class on-call support and Ask-an-Expert sessions when you need it the most.

Unmatched Training

We’re one of the largest engineering training providers in the world, offering both online and on-demand training so your team knows how to get the most out of your software.

Professional Services

Our dedicated Services team ensures a swift start with our design solutions, offering complete implementation, onboarding, consulting, and efficient upgrades for new mechanical design software.

Subscription Support

Frequently Asked Questions

At Hawk Ridge, we have dedicated electrical specialists who have helped many companies like yours become highly efficient with our electrical design solutions. We want you to get the most out of your investment, so we offer complete implementation and onboarding services where we get your software installed and walk you through an entire project. We also offer complete training (both live and on-demand), technical support, and mentoring to ensure you are creating efficient workflows and help solve your toughest electrical design challenges.

Yes. Hawk Ridge offers a comprehensive suite of training options for our electrical products including instructor-led foundation and advanced courses, personalized one-on-one training, and on-demand video training through our exclusive partnership with SolidProfessor.

That depends on the solution you are looking at. SOLIDWORKS Electrical Schematic runs independent of SOLIDWORKS 3D CAD, but you will need a license of SOLIDWORKS 3D CAD in order to run SOLIDWORKS Electrical 3D since it works as a way to connect electrical designs to the 3D model. SOLIDWORKS Electrical 3D is compatible with any version of SOLIDWORKS: Standard, Professional, or Premium.

SOLIDWORKS Electrical 3D is optimized for point-to-point wiring and is most effective in the layout of wiring for industrial machinery and automation. It can handle small harnesses, but for complex harnesses, or if your company specializes in harnesses, Enterprise Harness, may be a better solution.

Electrical Resources

SOLIDWORKS Electrical Schematics: What Else Can It Do?

Watch Webinar

Integrating Electrical and Mechanical CAD into Your Process

Read Article

Smart Schematics Trend: Are They Worth the Change?

Watch Webinar