Choosing a 3D printer that’s right for your business is a daunting task. With so many options on the market, how do you know where to start?

Here at Hawk Ridge Systems, we are experts in additive manufacturing solutions. We’re ready to give you the inside scoop on what you need to know to kick-start your 3D printing journey.

Choosing a 3D printer that’s right for your business is a daunting task. With so many options on the market, how do you know where to start?

Here at Hawk Ridge Systems, we can help you evaluate the right 3D printing technologies and also options like manufacturing on demand with our manufacturing services.

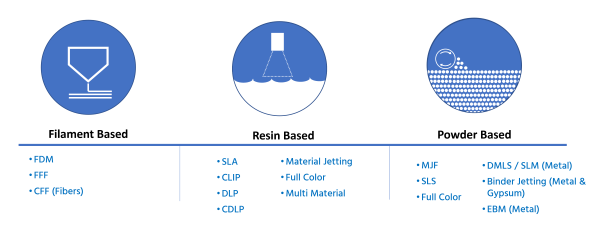

Common 3D Printing Technologies

The first step is understanding the printing technologies available.

The market is full of options, and a simple way to categorize them is to focus on the raw material that feeds each technology.

There are three main types:

- Filaments

- Resins

- Powders

Within each category, there are several specific technologies. FFF and FDM are the most common printers for filament-based systems. For resin-based systems, SLA will be the most common technology type. For powder, SLS and MJF will be standard.

The most popular technologies for metals are FFF, DMLS, and Binder Jetting. The Markforged Metal X is an example of an FFF metal printer.

Below is a chart showing several technology types.

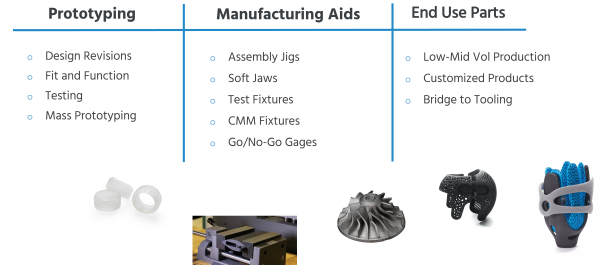

Applications and Use Cases for 3D Printers

The next step is thinking about how you will use your 3D printer.

3D printers have many applications and use cases that deliver major benefits across prototyping, manufacturing aids and end-use parts.

Prototyping is a widely recognized use for 3D printing, involving everything from fit and function checks to design revisions. Some of our customers have even invested in high-capacity production printers to handle mass prototyping in-house, efficiently producing large volumes of parts.

Manufacturing aids are an often-overlooked category that can save your organization money. You can replace jigs and fixtures traditionally manufactured using additive manufacturing, which is much quicker and cheaper. Technologies like Markforged continuous fiber reinforcement are capable of replacing machined aluminum parts in many cases.

End-use parts are becoming increasingly common applications for 3D printers due to the improved production speeds and cosmetic finishes comparable to industrial printers. Custom products such as insoles, orthotics and prosthetics are popular in this category.

Printing systems are also an excellent bridge to injection-molded tooling for end-use parts. That’s why we see many companies go to market faster with additive manufacturing.

Specific Examples of Filament, Resin, and Powder printing systems

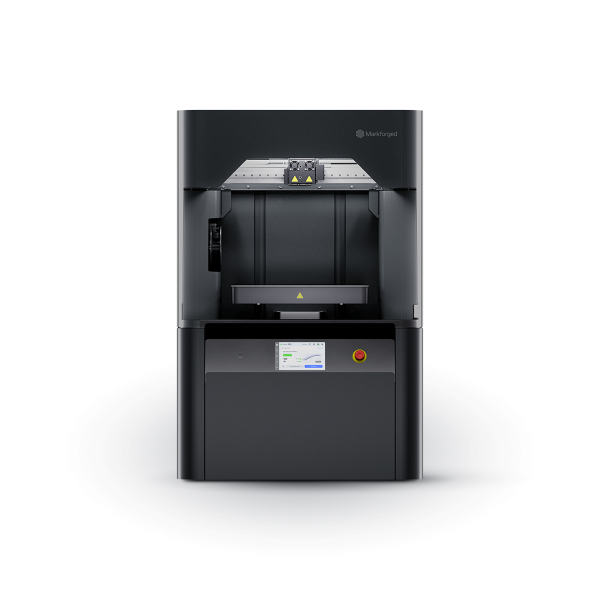

Filament 3D Printer – Markforged X7 and FX10 (FFF & CFR)

Markforged has made a name for itself with tough-as-nails 3D printers that produce incredibly strong parts on a reliable platform. These systems feature a simple-to-use workflow with best-in-class Eiger software.

Markforged Composite 3D printers’ bread and butter revolves around applications on the factory floor. Jigs and fixtures comprise a substantial portion of these applications, where 3D printers like the Markforged X7 and FX10 excel.

Markforged printers combine FFF printing with filaments and a second process called continuous fiber reinforcement (CFR). CFR strengthens plastic parts by around eight times, which can compete with or even exceed the strength of 6061 aluminum.

We have seen some incredible applications within our customer base. Some have taken advantage of the part cost, lead time reduction, and labor savings achievable by bringing in a Markforged 3D printer. Check out our live stream session here to learn more about Markforged 3D printers.

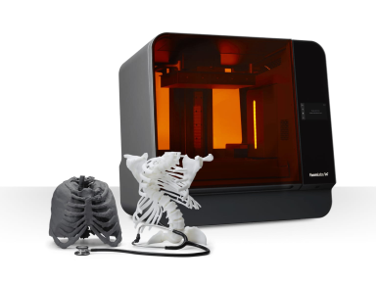

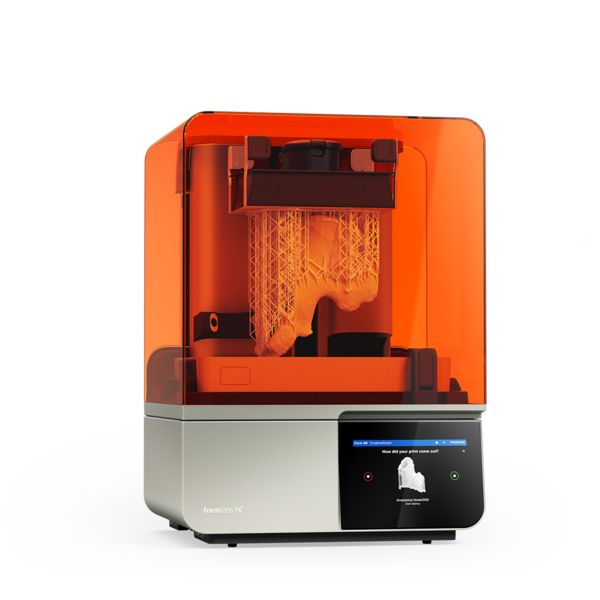

Resin 3D Printer Example – Formlabs Form 3L & Form 4

Resin 3D Printer Example: Formlabs Form 3L and Form 4

Formlabs has long been a leader in SLA resin-based printing systems. These printers are known for being workhorses designed for daily printing.

One key benefit of the Formlabs resin print platform is the wide range of materials available. There are over 30 material options for Formlabs resin systems, ranging from soft flexible elastomers such as Elastic 50A resin to incredibly hard technical ceramics such as Alumina 4N.

Resin printing systems also give you access to biocompatible and transparent materials, making the Form 4 and Form 3L platforms even more versatile.

What’s more, Formlabs printers produce exceptionally smooth surface finishes and fine print features, which are ideal for some of the most demanding applications.

Low-Risk Investment Strategies for 3D Printing Equipment

Understanding smart ways to invest in 3D printing equipment will go a long way — especially in the initial stages of evaluating additive manufacturing solutions.

Here at Hawk Ridge Systems, we have a dedicated team of professionals who are ready and able to provide guidance from our wealth of industry knowledge and expertise. Feel free to reach out to our team for a free consultation.

Here are our three tips for success as you begin your 3D printing journey.

#1 Start Small and Scale

Starting with the purchase of an introductory or low-cost 3D printer is a great way to enter the field of additive manufacturing. These systems are often easily scalable into print farms.

Learning to print on an introductory system will help users quickly dial in the most valuable features for their needs, so it’s easier to make informed decisions with future purchases of more sophisticated equipment.

We recommend looking at the Markforged Mark Two, X7, and FX10 for filament-based printing systems. Check out the Formlabs Form 3L and Form 4 for resin-based printing systems. And for powder-based printing, we recommend looking at the Formlabs Fuse 1+ 30W.

#2 Outsource Your 3D Prints to a Service Bureau (AKA Manufacturing as a Service)

If you’re unsure whether additive manufacturing will be a good fit for your business, consider outsourcing your prints. This is a great, low-risk strategy for proving a particular print process or technology with minimal investment. Once you’ve validated a print process, investing in the equipment in-house becomes easier.

Outsourcing also allows you to test top-of-the-line printing systems and technologies before making a significant investment. That way, you know exactly what’s needed before you make any moves.

Service Bureaus often have advanced finishing techniques, such as vapor smoothing or specialty paints, that can improve part aesthetics and/or performance. Hawk Ridge Systems has a service partner called A3D Manufacturing, based out of Tempe, Arizona. They have a shop floor containing the complete portfolio of print technologies that we offer, as well as traditional manufacturing technologies. They also have exceptional post-processing and finishing techniques to bring printed parts to the next level of quality and performance.

Explore Financing Options

If you have a strong use case that could immediately benefit from additive manufacturing, finance options may be the best choice for your business. Custom payment plans with deferred payments can be attractive, allowing you to secure the right equipment the first time.

If you decide to go this route, do your research and reach out to Hawk Ridge Systems for guidance. We have strong relationships with lenders who specialize in working with 3D printing equipment.

Our dedicated team of application engineers and sales experts is ready to help you understand the ROI for your specific use cases, ensuring you know if, when and how a 3D printer will pay for itself.

Start Your Journey with Hawk Ridge Systems

Now, you should understand what it takes to get started with industrial 3D printers.

For pricing and more information about industrial 3D print systems, feel free to contact us at Hawk Ridge Systems today.