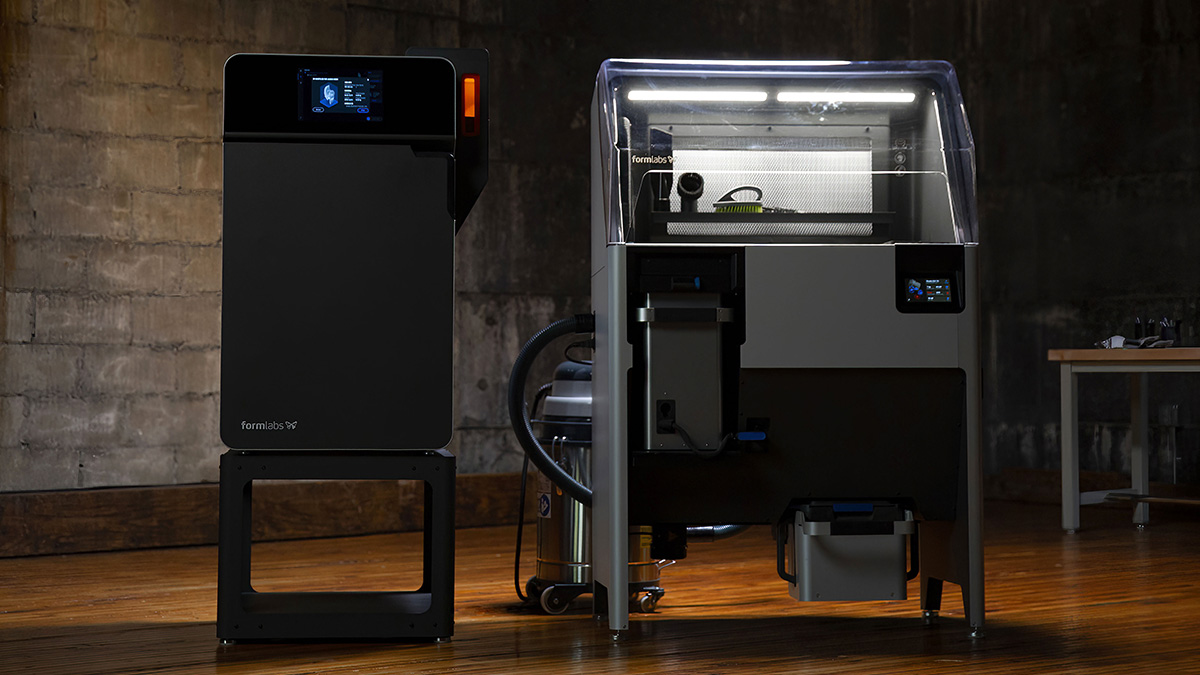

Formlabs Form 4

3D Printer

Form 4 is a blazing fast masked SLA 3D printer that combines an industry-leading materials library with a reliable, accurate print engine.

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

Game Changing 3D Printing Performance

Form 4 is a blazing fast masked SLA 3D printer that combines an industry-leading materials library with a reliable, accurate print engine. Turn your ideas into reality faster than ever with easy workflows, leading reliability, and stunning part quality using the Form 4 ecosystem.

Form 4’s speed is driven by Formlabs’ new Low Force Display™ Print Engine, a powerful combination of ultra-high power LEDs, collimating lenses, optical filters, and a robust liquid crystal display. Together they cure each layer of resin rapidly — regardless of part size or quantity. With tight tolerances, parts printed in every resin on Form 4 will match your design parameters, every time.

Core Resin Materials

Key Features & Benefits

Blazing Fast

Versatile

Intuitive

Reliable

Stunning Parts

Technical Specifications

|

Features

|

FORM 4

|

|---|---|

|

Build volume

|

20.0 × 12.5 × 21.0 cm | 7.9 × 4.9 × 8.3 in

|

|

Layer thicknesses

|

25 - 300 microns

|

|

XY Resolution

|

50 microns

|

|

Printer Dimensions

|

39.8 × 36.7 × 55.4 cm | 15.7 × 14.5 × 21.9 in

|

|

Weight of the machine

|

18.3 kg | 40.4 lb

|

|

Power requirements

|

100–240 VAC 2.5 A 50/60 Hz 220 W

|

Formlabs SLA Printers Deliver Impeccable Detail

Elevate your 3D printing game with Formlabs SLA 3D printers. Our cutting-edge technology offers unparalleled precision and detail, allowing you to bring your designs to life with stunning accuracy. Whether you’re prototyping, creating intricate models, or producing small-scale parts, Formlabs SLA printers deliver exceptional quality and reliability.

Experience the power of precision printing and unlock new possibilities for your projects with Formlabs SLA technology.

Most Prints in Under 2 Hours

Prepare

Post-Process

Finish

Formlabs Resources

Formlabs Is Here! SLA and SLS Printers

Read Article

MedTech Additive Manufacturing in Space

Read Article

Speed Up Medical Device PLM Processes

Read ArticleFrequently Asked Questions

Form 4 is the fastest SLA printer on the market with excellent reliability, print quality, accuracy, materials performance, and part size support. Most modern MSLA printers can deliver similar average print speeds (20-40 mm/hour) for their general-purpose materials. But they often have to sacrifice on reliability, print quality, supported part size, accuracy, and/or supported materials to achieve these speeds.

Yes, you can remove the parts from the Form 4/B build platform and use your existing Form Wash. But to fit the new Form 4 build platform which has 19% larger build area (note: 30% larger build volume), you’ll need to upgrade to the new Form Wash (2nd Generation). The maximum part size that can fit in the legacy Form Wash is 14.5 × 14.5 × 17.5 cm. Form Wash (2nd Generation) also has 3x more agitation and improved longevity allowing you to wash 67% more parts before replacing your solvent.

No. Formlabs redesigned the cartridge, resin tank, and build platform to achieve significantly better performance, lifetime, ease of use, and cost. To make those improvements, it wasn’t possible to make Form 4 printers backwards compatible with Form 3 series consumables.