Formlabs SLA 3D Printers

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

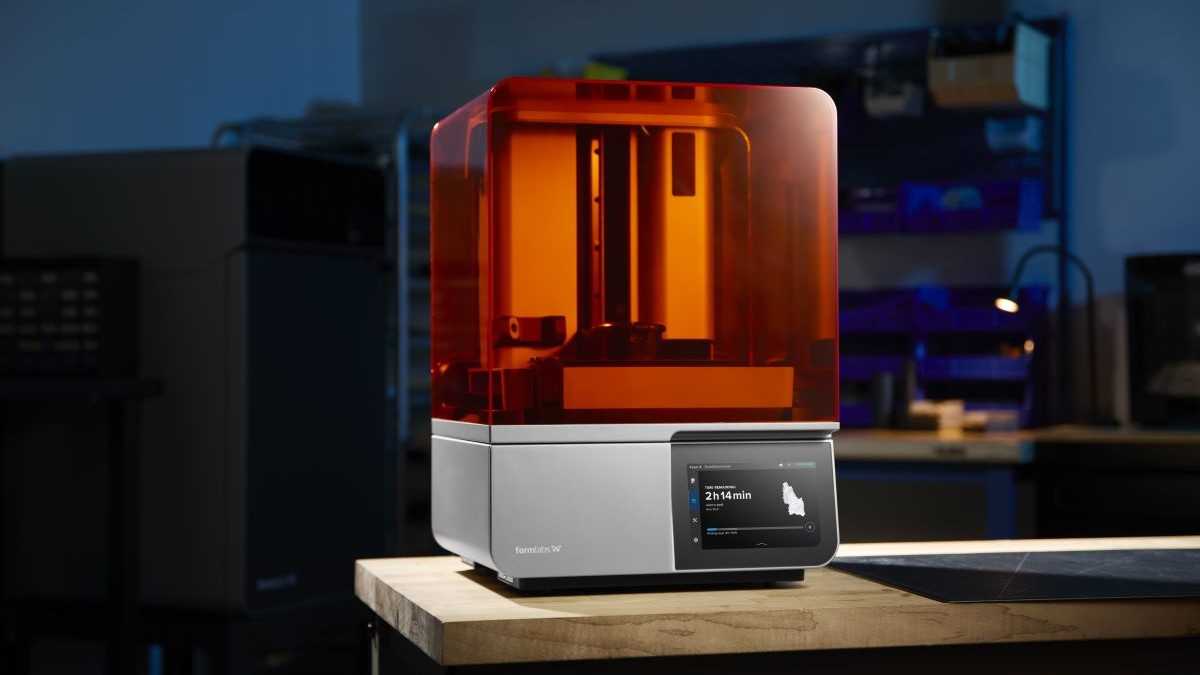

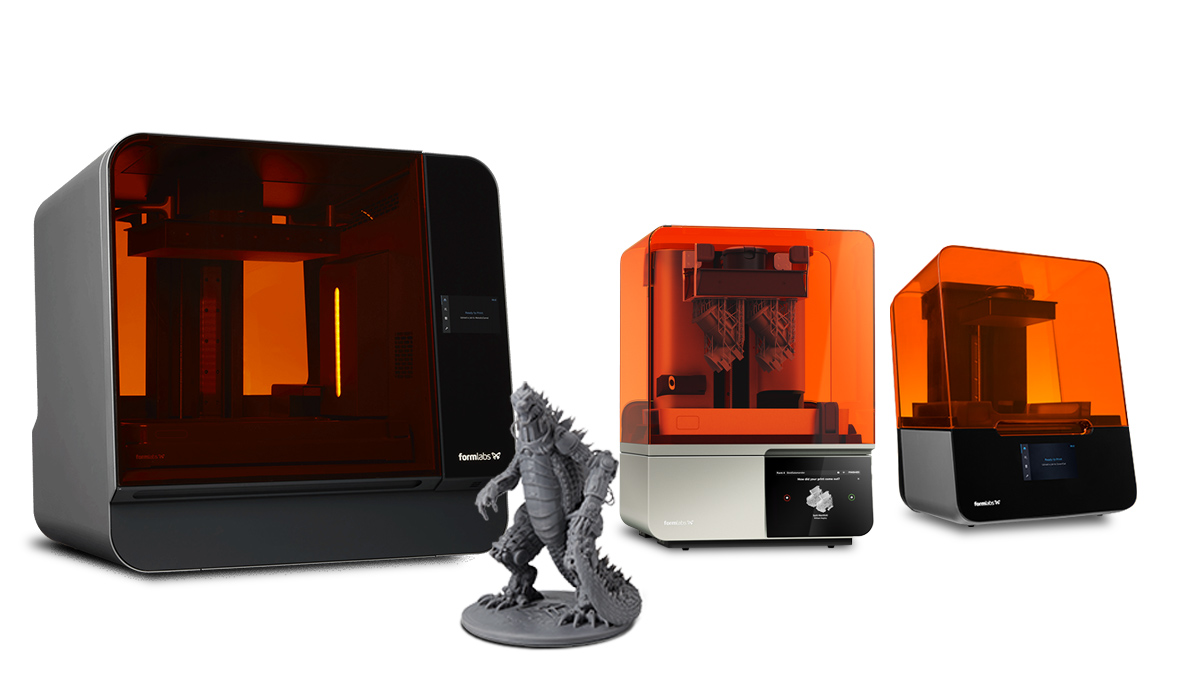

Precision, Detail, and Versatility in 3D Printing

Formlabs’ resin printers provide high-quality 3D printing solutions for diverse needs, offering accuracy, isotropy, and watertight parts in advanced materials.

The Form 3D printing ecosystem offers a variety of materials, including tough engineering resins and castable options, with automated resin systems for consistent results. Whether an engineer, artist, or hobbyist, Formlabs’ printers offer precision, versatility, and ease of use to bring ideas to life in 3D.

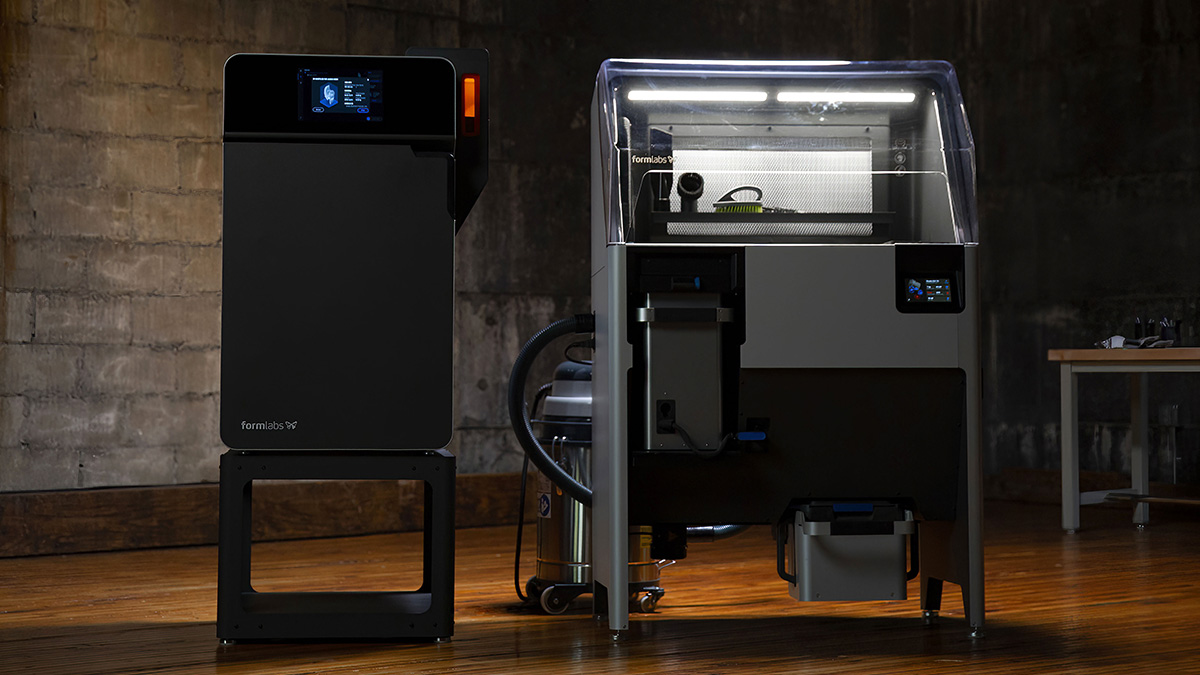

Resin 3D Printers Developed for Healthcare

Looking to print with biocompatible materials? Every Form SLA printer has a Medical/Dental certified version. The same 3D printer capabilities that offers the most diverse materials library for healthcare. Create biocompatible, sterilizable anatomical models and medical devices fast, with easy workflows, leading reliability, versatile materials, and stunning part quality using the Form B ecosystem.

3D print adult patient-specific anatomy at full, 1:1 scale or large medical devices with the Form 3BL, a large-format resin printer for medical applications, that’s compatible with the majority of our materials, including biocompatible, sterilizable resins made in our ISO 13485 certified, FDA-registered facility.

Technical Specifications

|

Features

|

FORM 3+

|

FORM 3L

|

FORM 4

|

|---|---|---|---|

|

Build volume

|

14.5 × 14.5 × 18.5 cm (X,Y,Z) 5.7 × 5.7 × 7.3 in

|

33.5 × 20 × 30 cm (X,Y,Z) 13.2 × 7.9 × 11.8 in

|

20.0 × 12.5 × 21.0 cm | 7.9 × 4.9 × 8.3 in

|

|

Layer thicknesses

|

25 – 300 microns .001 – .012 in

|

25ᶜ – 300 microns .001 – .012 in

|

25 - 300 microns

|

|

XY Resolution

|

25 microns

|

25 microns

|

50 microns

|

|

Printer Dimensions

|

40.5 × 37.5 × 53 cm (X,Y,Z) 15.9 × 14.8 × 20.9 in

|

77 × 52 × 74 cm (X,Y,Z) 30.3 × 20.5 × 29.1 in

|

39.8 × 36.7 × 55.4 cm | 15.7 × 14.5 × 21.9 in

|

|

Weight of the machine

|

17.5 kg/ 38.5 lbs

|

54.4 kg/ 120 lb

|

18.3 kg | 40.4 lb

|

|

Power requirements

|

100–240 VAC 2.5 A 50/60 Hz 220 W

|

100–240 VAC 8.5A MAX 50/60HZ 650W

|

100–240 VAC 2.5 A 50/60 Hz 220 W

|

Formlabs SLA Printers Deliver Impeccable Detail

Elevate your 3D printing game with Formlabs SLA 3D printers. Our cutting-edge technology offers unparalleled precision and detail, allowing you to bring your designs to life with stunning accuracy. Whether you’re prototyping, creating intricate models, or producing small-scale parts, Formlabs SLA printers deliver exceptional quality and reliability.

Experience the power of precision printing and unlock new possibilities for your projects with Formlabs SLA technology.

Formlabs Resources

Formlabs Is Here! SLA and SLS Printers

Read Article

MedTech Additive Manufacturing in Space

Read Article

Speed Up Medical Device PLM Processes

Read ArticleFrequently Asked Questions

Formlabs SLA printers are compatible with a wide range of materials, including standard resins, engineering resins, and specialty resins tailored for specific applications. These materials offer varying properties such as strength, flexibility, and temperature resistance, catering to diverse project needs.

Formlabs SLA printers are renowned for their high resolution and exceptional detail capabilities. With precise laser curing technology, these printers can produce intricate features and fine textures, making them ideal for creating highly detailed prototypes, models, and functional parts.

Formlabs provides intuitive and user-friendly software solutions for preparing and managing prints on their SLA printers. With features such as auto-orienting, support generation, and print scheduling, the software streamlines the printing process and ensures optimal results with minimal effort.