As vehicles integrate advanced electronics, electrification, and connectivity, repairability and interoperability are rapidly becoming pivotal design metrics for automakers and suppliers. Right-to-repair laws, sustainability mandates, and demands for cost-effective maintenance mean automakers and suppliers need to focus on crafting modular, accessible components. In this article, we’ll walk through how suppliers can embed repairability in design workflows for maximum repairability, profits, and customer delight.

What Design for Repairability Actually Means

Automotive and aftermarket part manufacturers have a lot to consider when designing the future of transport. Sustainable designs, long-lasting performance, and easy service are all top of mind, but these are just table stakes. Consumers expect ease of use in almost every domain – not just how well a vehicle holds up over time, but things like how hard or easy it is to get a part replaced or repaired.

Even the most perfect design may need repair at some point. There are 6 million transport accidents every year on average in the United States, according to the Department of Transportation. That’s a lot of parts to fix!

Customers expect simple over-the-air updates for software-defined vehicles, and they expect they can take their vehicle to any mechanic, not always the dealer, for routine maintenance and fixes. And mechanics expect vehicles to be designed in a way that makes repairs easy and fast. Designing for repairability means meeting these expectations simultaneously with right-to-repair legislation requirements.

Designing for repairability can mean making accessible fasteners, modular assemblies, and easily replaceable subcomponents. It also means making diagnostic data and support services easily accessible to repair shops, and ensuring architecture is open and not proprietary, especially for SDVs.

It’s not that suppliers can wildly differentiate themselves from competitors just by factoring design for repairability early. It’s that they avoid big mistakes that damage brand trust and crush customer loyalty by thinking ahead.

The two most important key ingredients in repairability-focused design are ease of access and modular assemblies that allow subcomponent replacement like EV battery cells or sensor units, without full disassembly.

Some Fails and Wins Concerning Design for Repairability

In the past couple of years, BMW piloted a subscription service for hardware that was already there (heated seat warmers). Customers were not happy. Around the same time, a simple headlight swap on some 2020-2023 7 Series models could only be done at the dealer due to proprietary calibration software. This locked repair shops out of servicing the issue, and again, didn’t exactly delight customers. Because of customer feedback (and lack of sales), the paywall to warm your tush disappeared, but the repair issue for headlights required independent repair shops to subscribe and pay for access to their proprietary diagnostic tool.

Ford had a similar faux pas with maintenance access in the 2010s that made it more difficult for simple oil changes. They used online complaint feedback from customers and shops, and took action, redesigning the underbody with quick-release panels and made the drain plug easier to access. For customers, repair shops, and fleet owners, this was a key win, cutting oil change time down to twenty minutes.

Overall, designing with repairability has several business benefits:

- Lower warranty claims with predictive tools, eliminating failures

- Reduction in lifecycle costs through longevity-focused designs (higher quality parts and components that last longer)

- Minimized waste and repair expenses due to modular components

- Faster repairs when interoperability is baked in

- Reduction in late-stage errors

- Shorter time to production and market, plus long-term financial incentives

- Happier customers

So, how can smart design tools support your quest to make more modular, maintainable, and accessible components for ease of repair? And which tools exactly?

Tools and Methods to Support Design for Repairability

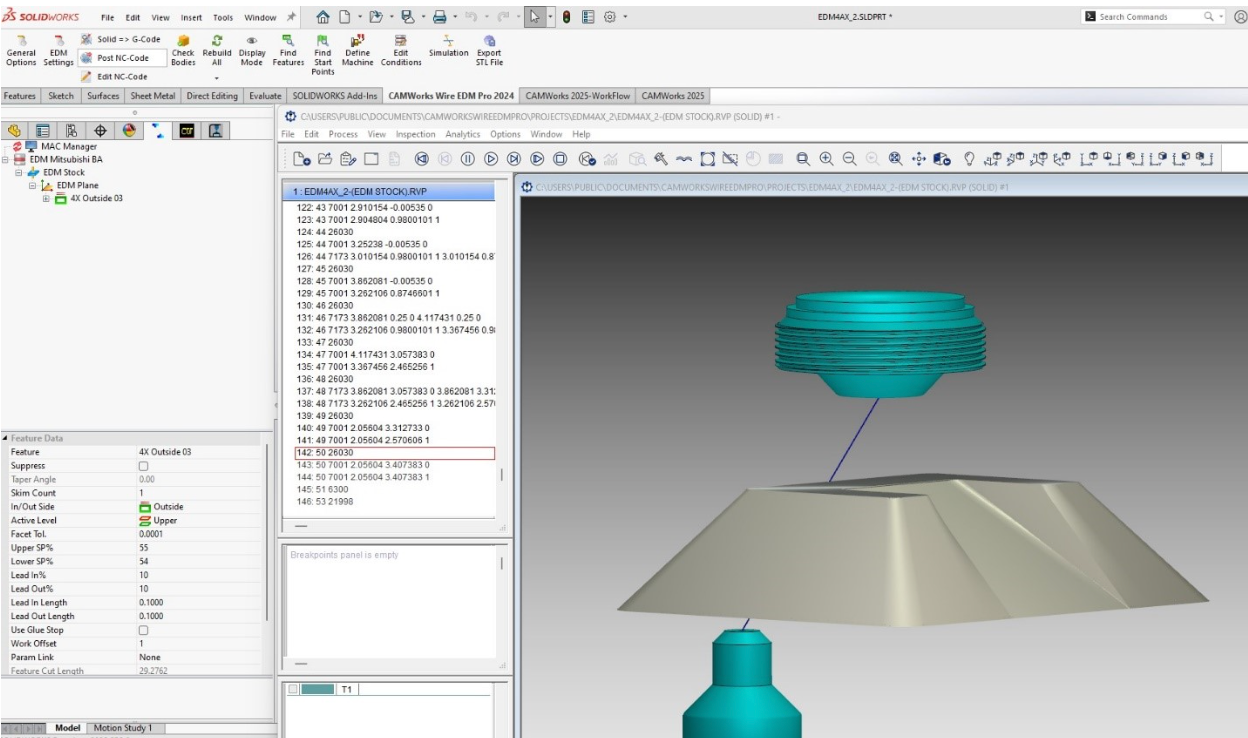

CAD, validation tools, and integrated design-to-manufacturing tech now make it easier to evaluate repairability upfront at the design stage.

- Use 3D modeling to simulate service scenarios and create digital repair guides that visualize disassembly paths and tool requirements

- Virtual disassembly analysis and maintenance analysis can help you assess maintenance times and costs

- Making Data Accessible: Linking design to aftermarket service documentation streamlines service

- Integrations: CAD-integrated platforms can help you generate interactive manuals, ensuring compatibility with OEM schedules for tasks like oil changes or brake inspections

These methods reduce errors and support compliance with regulations mandating repair information access like right-to-repair laws.

Hawk Ridge Systems: Designing for Repairability at the Start

Interoperability is paramount for the future of SDVs, but means nothing if repairability isn’t the star of the show. These are foundational principles in automotive design with important financial and customer loyalty benefits downstream if done right.

The tools you use matter, but the strategy is more important. Take note of both industry pitfalls and triumphs to future-proof YOUR strategy.

Hawk Ridge Systems supports these strategies for customers like Knapheide, Speedway Motorsports, and RPG Offroad in their quests to factor in design for repairability from the start.

Know More: Download the Automotive Supplier User Manual