Automotive suppliers and manufacturers are battling relentless pressure: non-negotiable OEM deadlines, EV/ADAS (Advanced Driver-Assistance Systems) complexity, and a persistent shortage of qualified and skilled workers. These 5 gridlocks are choking throughput and margins today for many automotive companies — but each has a fast, high-ROI fix you can implement now.

1. Labor Shortages & Skills Gaps

Automotive manufacturing faces massive employment gaps. Despite billions invested from major OEMs in the American automotive market, companies struggle with hundreds of thousands of unfilled skilled roles. Reports from Deloitte and The Manufacturing Institute say almost 2 million jobs could remain unfilled in the coming years if the labor gap isn’t fixed.

The problem requires a massive, coordinated effort at a high level, and we don’t happen to sell any hardware, software, or services that deploy a magic fix to forces beyond all of our control.

However, there are mitigation strategies FULLY within your control you can implement that aren’t dependent on what happens in the market or in the global economy.

Quick Wins:

Train the Team: Launch aggressive upskilling programs right now. Use on-the-job training and make senior-to-junior knowledge transfer part of the factory floor vibe. Upskill team on AI and cobot certification training.

Use Engineering & Design Learning Platforms: Bring on an integrated learning platform like SolidProfessor (CAD/CAM & Design/Engineering Online Learning Platform)

Involve the Community: Consider partnering with local technical schools – students get the hands-on experience they need, and you get extra help on the factory floor

Companies doing this see immediate morale boosts, faster adaptation, and higher productivity. Many leading companies, universities, (and even the U.S. Air Force!), use engineering and design training platforms like SolidProfessor to keep skills sharp.

2. Growth of EV/ADAS Components & Complexity

The transition from ICE to EVs and ADAS (Advanced Driver-Assistance Systems) is complex and has changed manufacturing factory floors dramatically. Many manufacturers operate with mixed production lines, which introduce sequencing issues, different cycle times, and additional space needs (or potential reconfigurations of the factory floor).

Quick Wins:

Reconfigure it Virtually: Deploy digital twins for virtual testing and rapid reconfiguration. They deliver the fastest, highest ROI by simulating new setups quickly without moving equipment — crushing complexity and enabling flexible production.

Use Your Printer or Order a Part: 3D print tools, jigs, and fixtures to keep production lines running smoothly. No 3D printer in-house? Consider bringing in one of the Markforged printers or get parts printed on-demand quickly with manufacturing as a service.

3. Downtime, Siloed Systems & Disconnected Tools

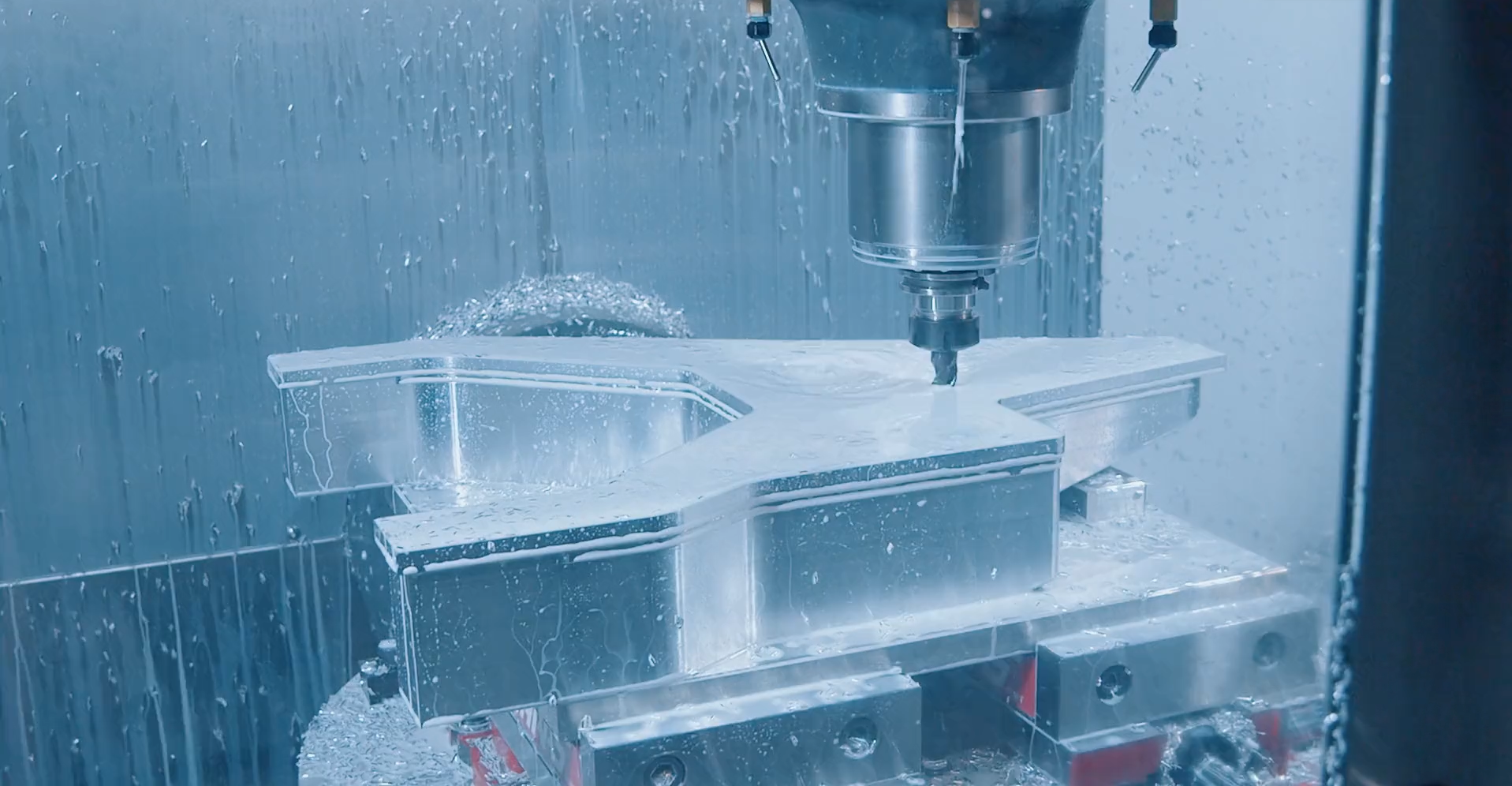

Miss a deadline with an OEM and you are out. Unplanned downtime means risking OEM penalties and damaging partner relationships. Disconnected tools (like CNC w/out CAMWorks or disorganized CAD files and data) aren’t helping either.

Quick Wins:

Add Data Management Software: Adopt affordable PDM to centralize files.

Standardize: Get CAD-integrated CAM software to standardize programming.

Get New Machines: Bring in a 3D printer like the Markforged X7 for quick end of arm tooling replacements.

Add Sensors: Add basic (low-cost) IIoT sensors for predictive maintenance on key machines.

4. Idle Machines Outside Shifts (No Lights-Out Automation)

Lights out automation could bring enhanced productivity to your manufacturing operation, but it all depends on how you implement it.

True “Lights Out” or “Dark Factories” are exceptions rather than the norm, with many OEMs leveraging lights out automation for specific sections of the floor – not the entire factory.

Former VP of Operations at Nevada’s Tesla Gigafactory, Chris Lister commented that often when one bottleneck gets fixed, it reveals other bottlenecks later down the line, so it’s a continuous optimization process to either add or subtract automation workflows.

In smaller automotive aftermarket companies, the usage of lights-out automation in any part of the factory floor is commonly (but not always) limited to operations like CNC machines running overnight or robotic cells for specific tasks. For one manufacturer, they found that adding lights out automation to their CNC operations during the last one to two hours of every shift was how they could increase productivity.

Quick Wins:

Don’t Try to Automate Everything, Start Small: Implement lights-out automation in specific areas of the factory floor with cobots and predictive maintenance.

Get Software to Optimize Robotic Workcells: Use DELMIA Factory Automation & Robotics to create, simulate, and optimize programs for the entire robot workcell and robot trajectories.

Don’t Automate Something That Needs Human Oversight: Look at areas you already have automation and assess bottlenecks – Are there tasks that require human dexterity and assessment that could speed up the station?

5. Unoptimized/Poor Shop Floor Layout Causing Congestion

Small facilities often have layouts that create bottlenecks — material pileups, long walks for parts, or machines blocking flow. Without budget (or time) for major redesigns, these inefficiencies waste time and space. Make time if you can’t make budget for this bottleneck.

Quick Wins:

Use the Computer in Your Pocket: Use free/low-cost 3D scanning and layout tooling to test new layouts. Scan your floor with your phone then import the OBJ/PLY into SOLIDWORKS. Overlay new machines, printers, cobots, and racks in their exact future locations.

Get Professional Layout Software: Use SOLIDWORKS Facility Layout (included in Premium) for quick 3D digital mockups. Check clearances, generate professional drawings, and share with stakeholders — all without leaving SOLIDWORKS.

Make it Fun: Want a break from the screen? 3D-print your machines and stations and turn facility layout into a tabletop game to redesign the factory floor.

Need more tips to update the shop floor? Contact us or grab our brand-new guide to Future-proofing the automotive shop floor.