Hawk Ridge Systems is a leader in SOLIDWORKS 3D CAD across North America, serving a range of customers in industries ranging from industrial equipment to medical devices. Naturally, helping these companies design and manufacture quality plastic parts has long been one of our core success stories.

While the parametric modeling features in SOLIDWORKS have always enabled designers to create complex part designs with detailed surfaces and tolerancing information, finding a way to manufacture these parts efficiently has often been a deeper challenge. Thankfully, Hawk Ridge Systems has over the years expanded to the rest of the SOLIDWORKS product portfolio and beyond to help bridge those gaps.

SOLIDWORKS Plastics Guides the Design of Injection Mold Tools

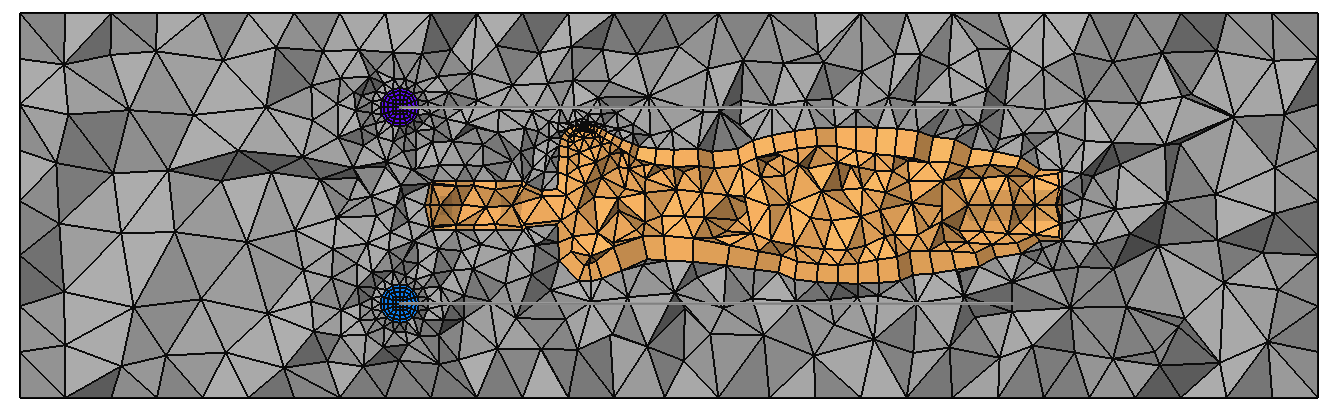

One of the biggest challenges in molded part design is determining a gate location for your injection mold that can efficiently fill the mold while providing for a quality part free of defects. SOLIDWORKS Plastics, the add-in for simulating the injection molding process for plastic parts, has served as a quick way for designers to check the filling process of their part before spending time designing a mold or cutting steel.

Those capabilities were enhanced with the release of SOLIDWORKS 2022, which included the new Injection Location Advisor feature. This tool within Plastics allows designers to instantly scan any part and see a recommendation for the ideal gate location on the party cavity, with the option to specify tool setup factors such as the parting direction or keep-out areas (for things like core pins, embossed logos or other important features). This tool even creates the sketch geometry necessary to define the gate, which can be further modified or dimensioned by the designer as the part design is revised.

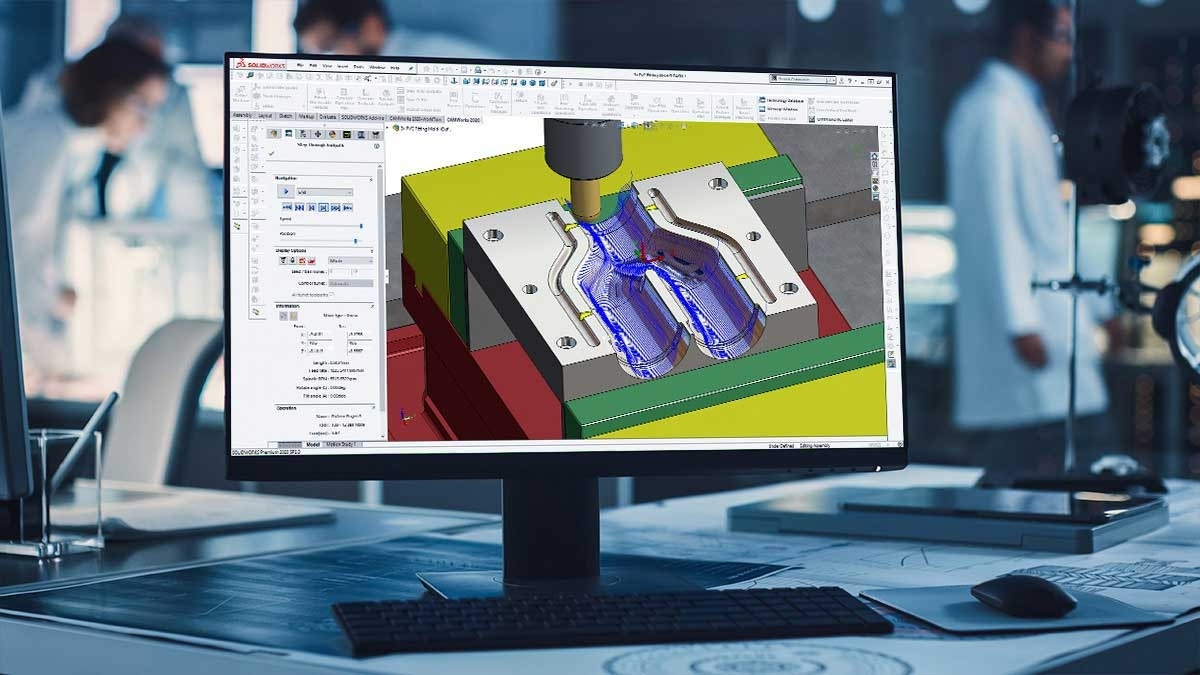

Once the initial part design is finalized, SOLIDWORKS Plastics can take analysts further into the process, simulating the entire mold setup (including runner systems and cooling channels) through the entire filling and packing process. This realistic molding simulation ensures all features of a mold tool are dialed in to maximize part quality and minimize defects such as part warpage, both from in-mold stresses and thermal quenching.

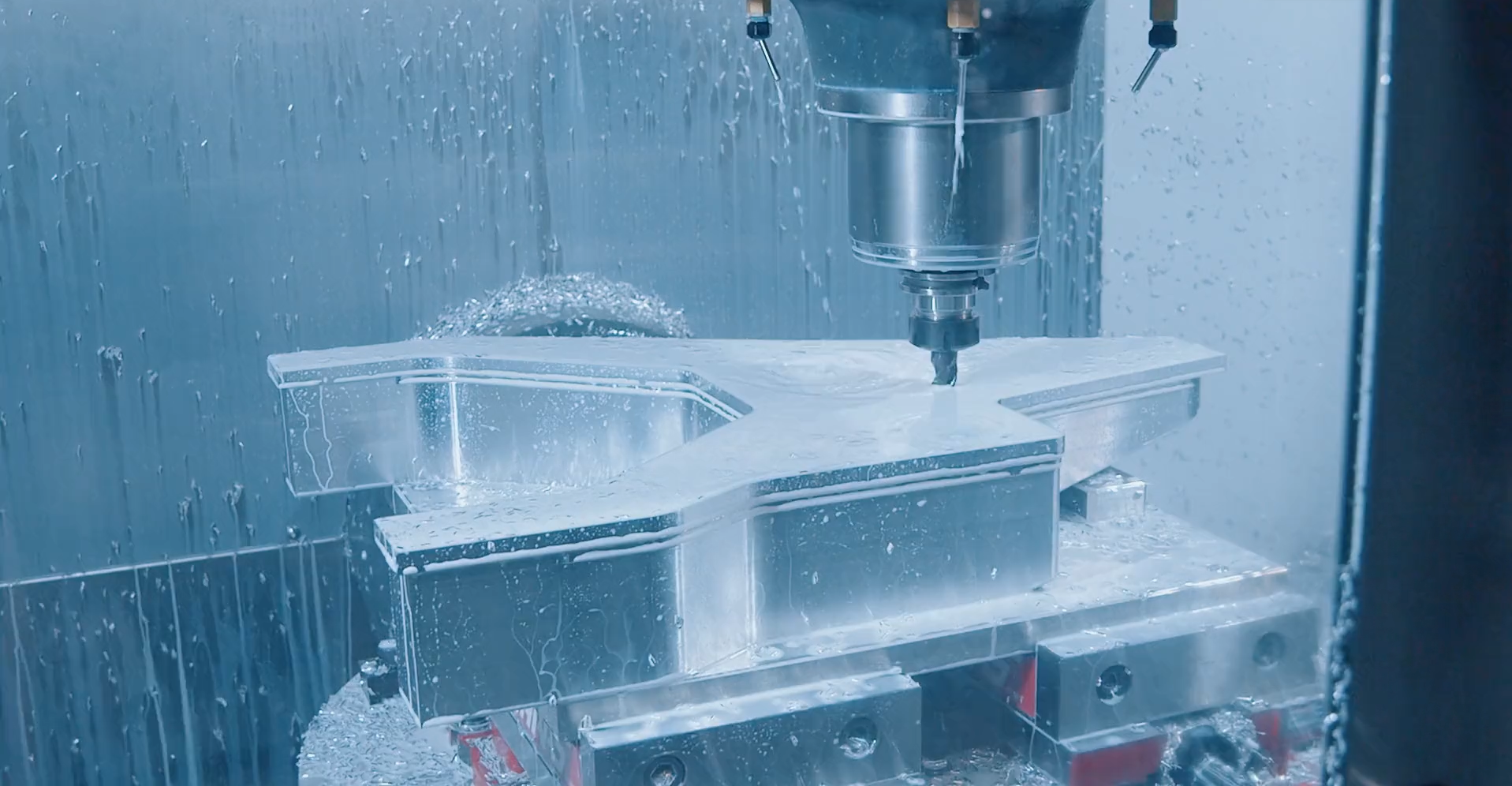

Once the ideal mold setup is identified, SOLIDWORKS users can feel confident investing the time into the detailed tooling design, creating a test print, and generating toolpath with CAMWorks CNC programming.

Watch Webinar Now

Check out our recently held webinar for a more detailed look into how SOLIDWORKS Plastics and the rest of these tools were used to design a plastic injection molded beer tap.

For more information on how SOLIDWORKS tools can fit your application, don’t hesitate to contact us at Hawk Ridge Systems today. Thanks for reading!