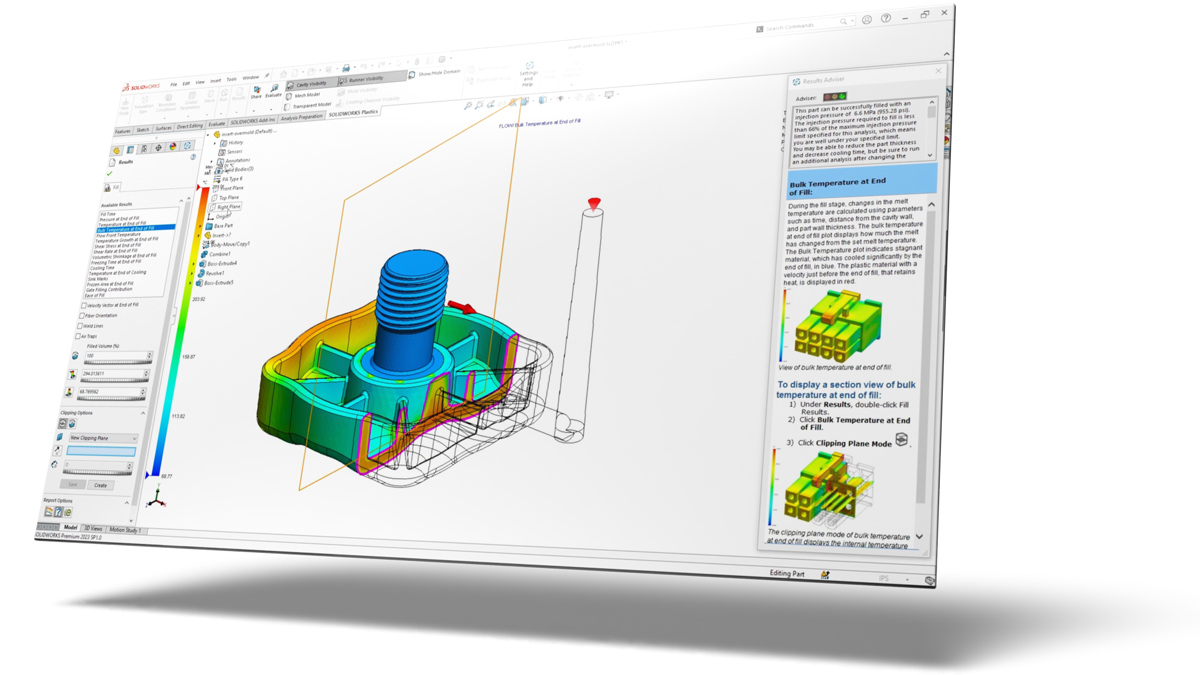

SOLIDWORKS Plastics

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

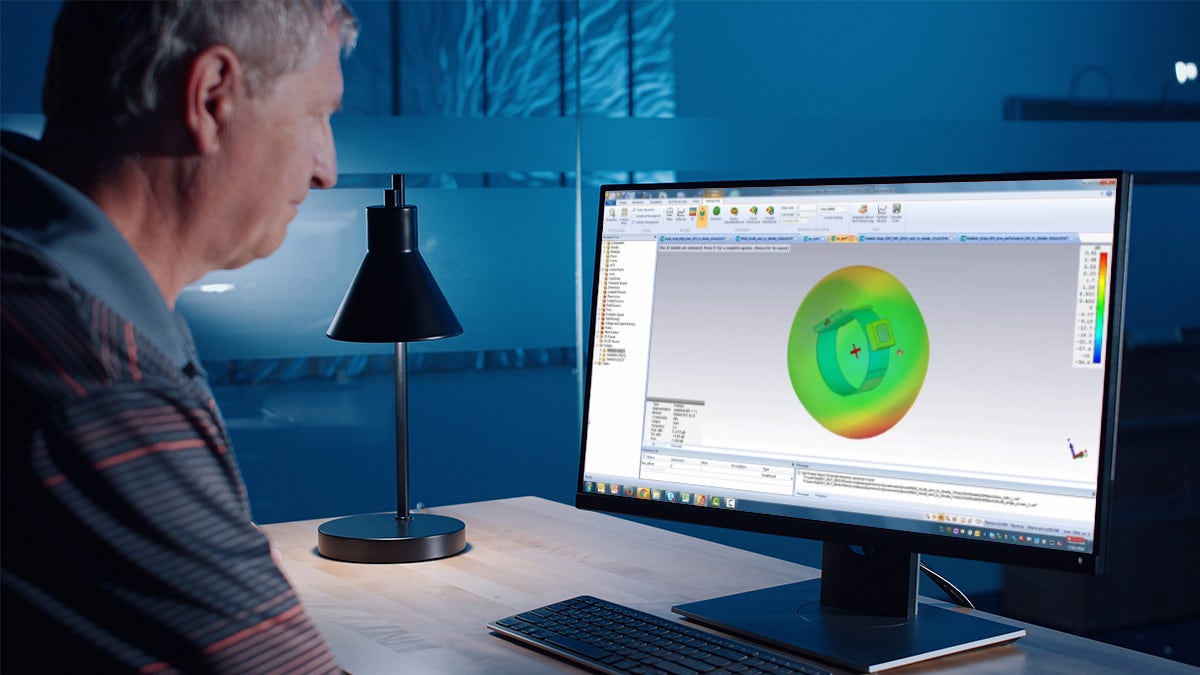

Built-in Injection Molding Simulation for SOLIDWORKS

Go beyond the existing mold design capabilities available within SOLIDWORKS 3D CAD. SOLIDWORKS Plastics was created specifically for plastic part and injection mold designers, providing you with the tools you need to easily identify potential manufacturing problems earlier in your design process. This easy-to-use solution helps you to simulate and predict mold filling patterns, prevent product defects, and reduce your costs and product development timelines – all directly in your familiar SOLIDWORKS interface.

With SOLIDWORKS Plastics, you can be confident in your part design before ever cutting steel for the mold.

-

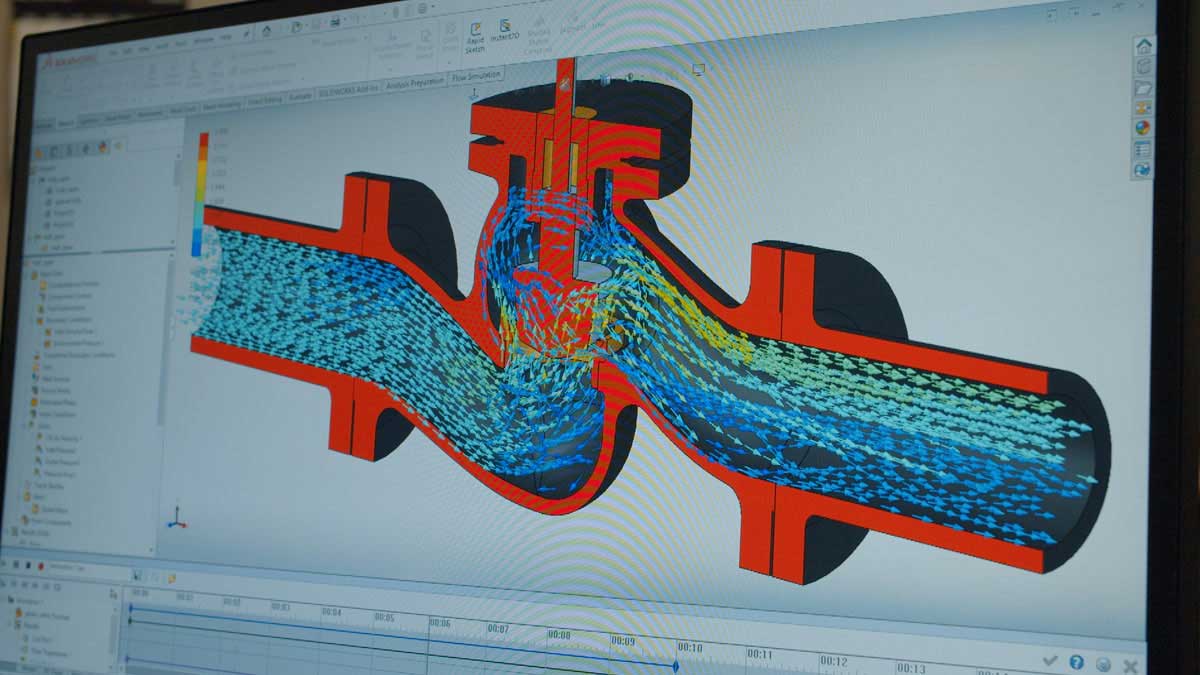

FillingAnimate filling pattern inside a mold cavity.

-

Short ShotsDetermine whether a given molding machine can successfully fill a part.

-

Weld LinesVisualize problem areas where plastic melt recombines.

-

Sink MarksPredict location of surface depressions due to sink.

-

Multiple GatesCompare mold filling for one or many gates.

-

Nominal Wall Thickness AdvisorCheck part geometry for walls that are too thick or too thin.

-

Air TrapsPredict air trap locations.

-

Venting AnalysisSpecify vent locations to predict air pressure in the mold cavity.

-

PackingEstimate shrinkage based on packing stage parameters.

-

Gas Assisted InjectionSimulate gas-assisted co-injection for hollowed out parts.

-

Valve GatesInclude gates that shut on/off during molding cycle

-

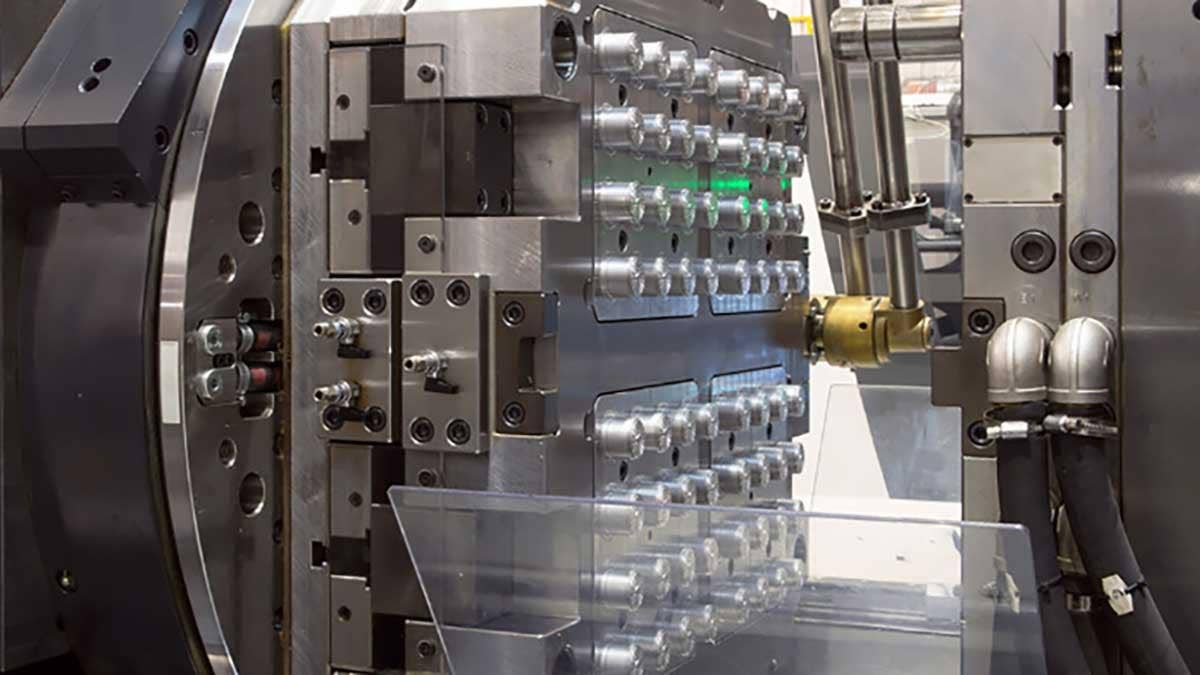

Multiple Cavity MoldsSimulate full mold layout including runner system and sprue.

-

Runner BalancingAutomatically find optimal runner sizes for even mold filling.

-

Co-InjectionSimulate injection of multiple materials.

-

Insert Over-moldingPredict flow around plastic or metal inserts.

-

ShrinkagePredict volumetric shrinkage in a part.

-

Cycle TimePredict total cycle time for filling, pack, and cooling.

-

Fiber Analysis & BirefringencePredict fiber orientation and optical effects.

-

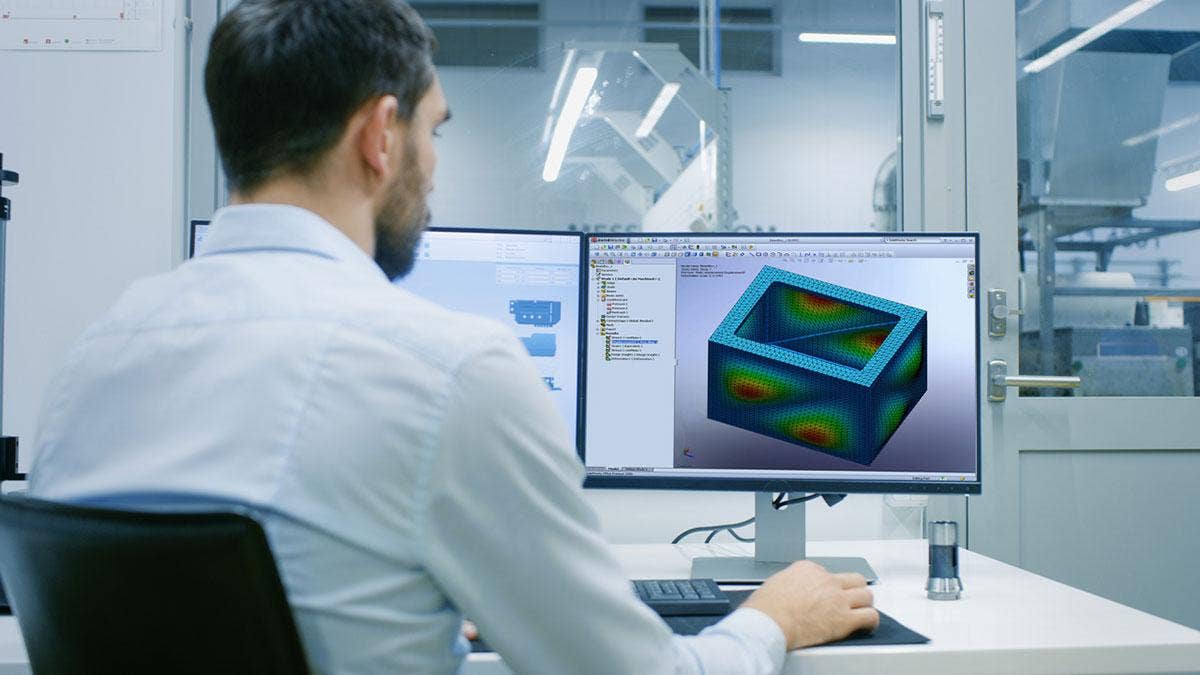

Part WarpageCalculate deformed shape of part based on internal stress.

-

Cooling Line AnalysisCalculate the actual temperature distribution in a mold based on cooling system design.

Exceptional Solutions, Even Better Support

Creating the best products requires the best solutions, training, and support. With a little insight into your product development process, our team of pros can point you to any tools you need (and nothing you don’t).

But it doesn’t end there. We’ll stay with you every step of the way, helping solve complex design issues, 3D printing application questions, and so much more. No matter where you’re at, both in your process and geographically, we’re here.

Simulation Resources

Confidently Design Quality Plastic Parts

Watch Video

End-To-End Simulation Handbook

Download Guide

Quickly Predict Your Design’s Real-World Behaviors

Watch Video

Powerful Electromagnetic Simulation on the Cloud

Watch VideoFrequently Asked Questions

Services & Customer Benefits

Technical Support

The simulation experts on our technical team are available to assist with all your analysis questions and software troubleshooting, whether it’s a quick tech support call or an in-depth ‘Ask-an-Expert’ session.

Plastics Training

We’ve added extra content to our SOLIDWORKS Plastics training, covering best practices and tips for project success. Choose from on-demand or live, instructor-led sessions to suit your schedule.

Professional Services

Leverage the expertise of our simulation team through consulting on your next project. We can assist you in developing your strategy and analysis approach to ensure the accuracy of your results.