Industrial equipment manufacturers design, build, and deploy high-performance heavy mobile equipment for rough, tough, complex jobs. Manufacturers in this vertical also design and build robotics for use on the production line or create specialized manufacturing equipment.

Think of brands like The Boring Company, which creates massive machinery to drill underground tunnels, or agricultural and farming equipment machinery designed and created by John Deere that supplies harvesters and planters to farmers across the world.

Or consider Knapheide’s highly customized work truck bodies designed and supplied to many companies across various industries – utilities, construction, agriculture, and more. They design and create these different truck bodies with tools like SOLIDWORKS CAD, PDM, Composer, and DriveWorks.

And with the rise of robotics and automation, some companies in this space focus on 3D printing custom grippers and additions in-house for robots and cobots. This allows them to add automation to the factory floor to reduce human error, do jobs that are unsafe for people to perform, and expedite workflows.

While their unique focuses may vary, the demands they face are roughly the same. These brands have hardcore regulatory compliance and safety demands to meet, as well as the normal demands to cut time to market, make machines more efficient, add automation where they can, and customize machinery for client-specific needs.

Read on to see what kinds of software and hardware these companies use to get the job done.

The Best Software Solutions Used by Industrial Equipment Manufacturers

Every company is going to have unique challenges and a different approach to solving them with software solutions, and while software can’t do it all, the right product development software can help you add automation, enhance quality, and shorten design cycles.

Here’s how two leading industrial equipment manufacturers streamlined their production with design to manufacturing software.

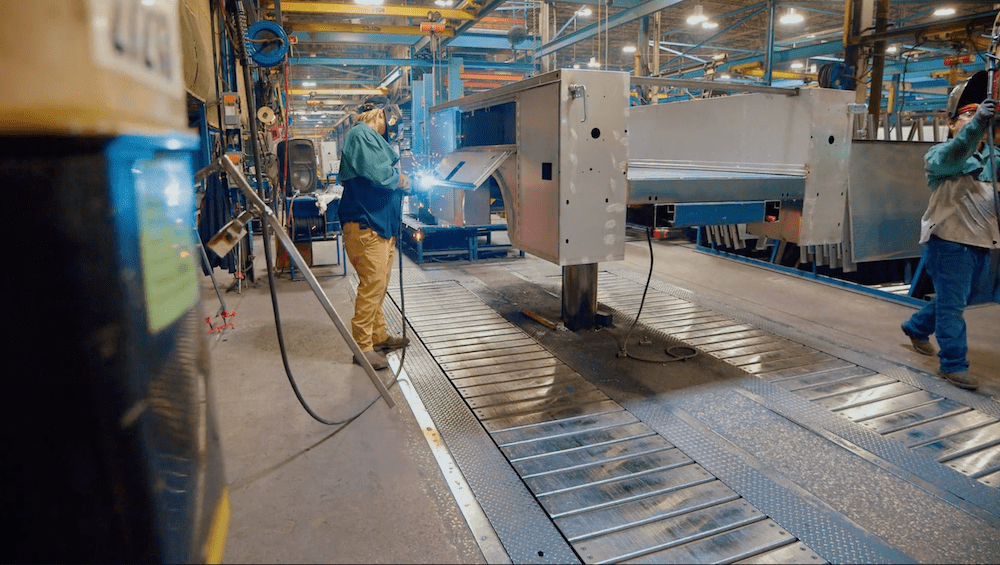

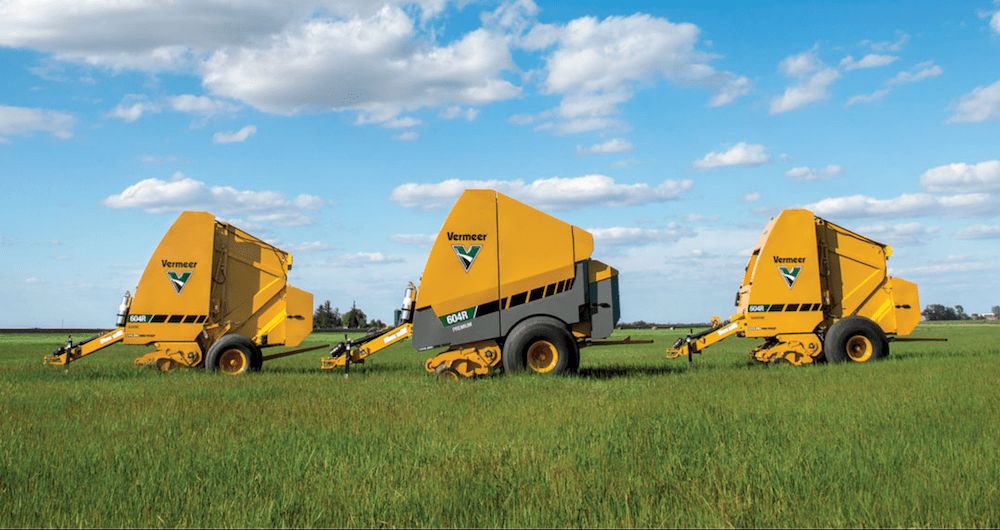

Vermeer Streamlines Production for Large Assemblies with SOLIDWORKS

Vermeer is a leading supplier of industrial and agricultural equipment. They design and build custom machinery for farming uses and machinery that helps workers deploy and route fiber optic cables. This company has machines with extremely large assemblies (we’re talking in the 10k+ part range.)

Vermeer streamlined their production throughput for machines with large assemblies and automated their engineering change process to enhance quality using:

ABCO Automation, Inc. Accelerated Their Time to Market by 25% with SOLIDWORKS PDM

ABCO Automation designs and makes custom automation equipment. They also integrate FANUC and KUKA robots. They got their start with well-known beverage brand Coca-Cola, creating electrical control systems and custom packaging equipment.

Their client base is now extremely diverse – and includes aerospace, food & beverage, tobacco, automotive, and healthcare.

By adding SOLIDWORKS PDM, ABCO:

- Shortened design cycles by 35%

- Cut development costs by 25%

- Reduced scrap/rework costs by 55%

- Automated their BOMs (Bill of Materials)

Companies use SOLIDWORKS PDM as a core data management system to standardize processes and automate repetitive or manual processes. ABCO uses it for more – integrating it with their ERP and running macros to mine the data in the PDM as part of one of their workflows.

The Top 3D Printers Used by Leading Industrial Equipment Manufacturers

In addition to design and manufacturing software like SOLIDWORKS, DriveWorks, and more, companies are also increasingly turning to 3D printing to quickly produce tooling, jigs, fixtures, and more in-house. Curious to see what kinds of 3D printers they use?

IBL Hydronic: Getting Prototypes to Customers in Days with Formlabs

IBL Hydronic, a company specializing in complete hydraulics and electronic systems for construction, agricultural, and forestry machines, uses the Formlabs Fuse 1 SLS 3D printer to produce complex hydraulic end-use components and control panels for agriculture machinery, which need to be tailored to specific machines.

With 3D printing, they get the first prototypes into their customer’s hands in two to three weeks.

RAPID Robotics: Creating Lightweight AI-powered Robotics with Markforged

RAPID Robotics designs and creates end-of-line robotic solutions for packing, palletizing, and kitting that are powered by generative AI and 3D vision. They design and iterate end-of-arm-gripper attachments for clients in less than one day, with a 30% reduction in weight compared to off-the-shelf options.

The tools they use to get it done? They’re using Markforged 3D printers to design and build custom end-of-arm robotic attachments and grippers for all types of different use cases where out-of-the-box solutions simply don’t cut it.

A Blueprint for Industrial Equipment Manufacturers

At Hawk Ridge Systems, we help industrial equipment manufacturers get the types of results we mentioned above. Now that you know what is possible with the right hardware and software, why not borrow some advice from the brands we highlighted in this article?

Contact us or grab a copy of our latest report: Industrial Equipment Manufacturers Industry Report: A Blueprint for Increased Uptime, Efficiency and Innovation, where we cover all the things you need to know to achieve similarly stellar results:

- Trends shaping the industrial equipment industry

- Biggest challenges and solves

- Success stories from how other leading manufacturers get it done