With the launch of Inconel 625 and D2 Tool Steel, the Markforged Metal X is now able to print parts in five different metals. With these five available materials, it is easier than ever for users to print parts with a metal that fits their application. In today’s blog, we’ll be taking a closer look at the Markforged metal material portfolio.

How the Metal X Works

Earlier this year, we demonstrated how the Metal X process is able to produce 3D printed metal parts with properties similar to that of machined components. If you would like to take a closer look at the Metal X technology, feel free to take a look at our blog post, “An Introduction to Metal 3D Printing” or watch the recording of our Metal X webinar below.

Metal Materials

With a base understanding of how the Metal X works, let’s take a look at the strengths and some uses for all metal materials that are currently available. The following sections will also include datasheet downloads for their respective materials.

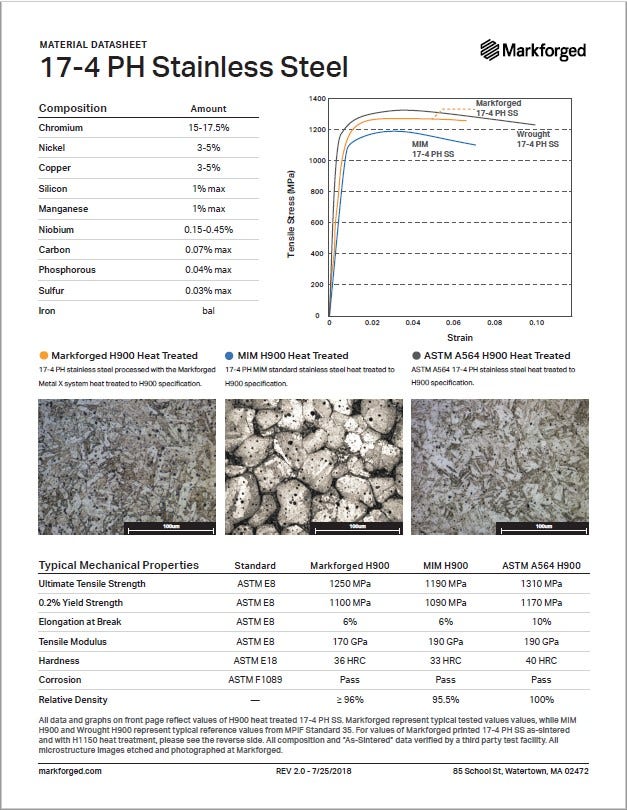

17-4 PH Stainless Steel

As the first publicly available Markforged metal material, 17-4 PH Stainless Steel has good general properties and is easy to work with. This material is typically known for good corrosion resistance and strength, but also for its ability to be easily heat-treated.

As you will see in the 17-4 datasheet below, Metal X parts share similar mechanical properties to machined parts of the same material, which allows for Metal X parts to be post-processed in any way that would be applicable to the base material.

Click on the above illustration to download the Metal X 17-4 PH Stainless Steel Datasheet.

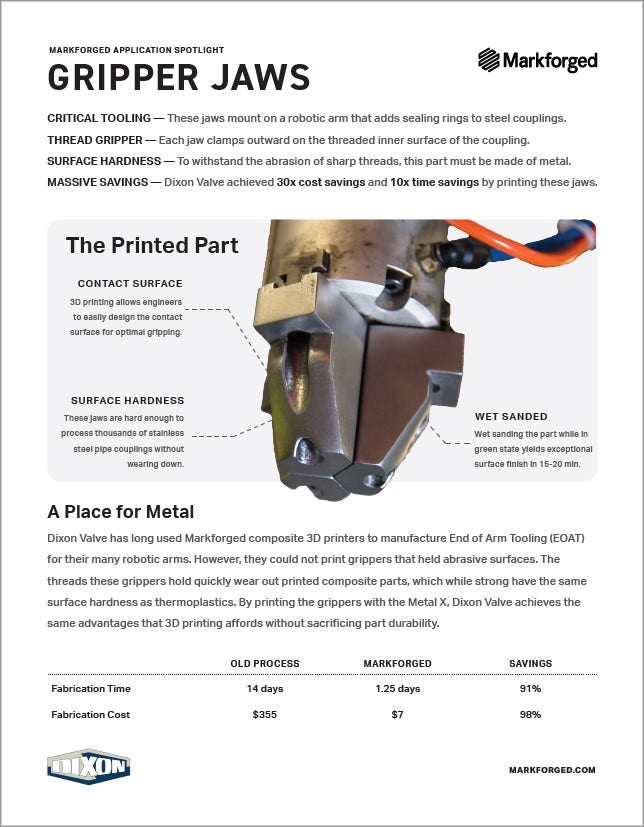

17-4 Stainless Steel is commonly used by Metal X users for a wide range of tooling applications. Dixon Valve & Coupling was able to replace some of their traditional gripper jaws with Metal X versions, reducing the cost and turn-around time for each component.

Click the above illustration to download the Dixon Valve & Coupling Use Case.

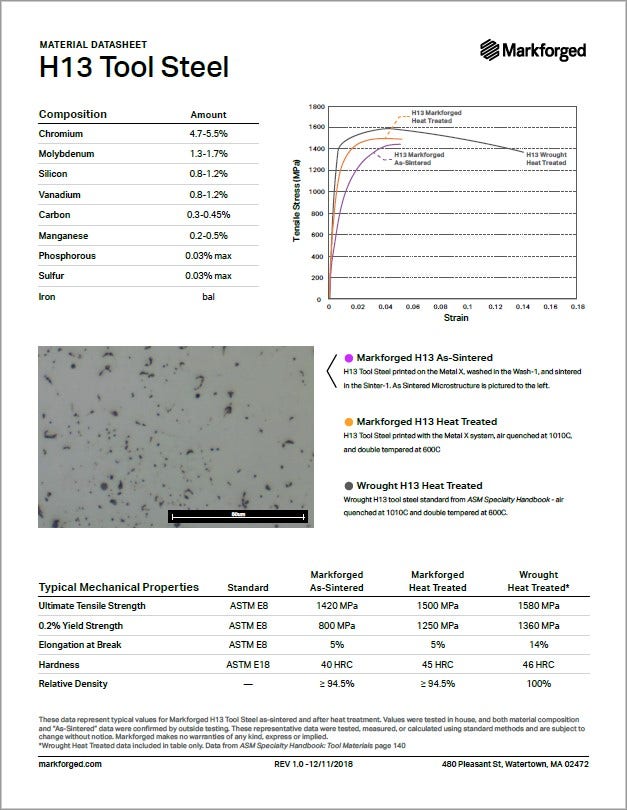

H13 Tool Steel

The second material that we’ll go over is H13 Tool Steel. H13 Tool Steel is known for having good hardness, excellent strength and high wear resistance. These properties make H13 an excellent choice for tooling applications such as punches or dies. This particular Tool Steel also has good heat resistance, which makes it commonly used for injection molding applications.

Click the above illustration to download the Metal X H13 Tool Steel Datasheet.

H13 Tool Steel is a hot work steel, which means that any post-processing needs to occur after the material is heated to a temperature relative to its melting point. This makes using the Metal X to print H13 parts especially useful, as green state parts can be easily pre-processed via wet sanding. Learn more about the different states of Metal X parts in the “How the Metal X Works” section above.

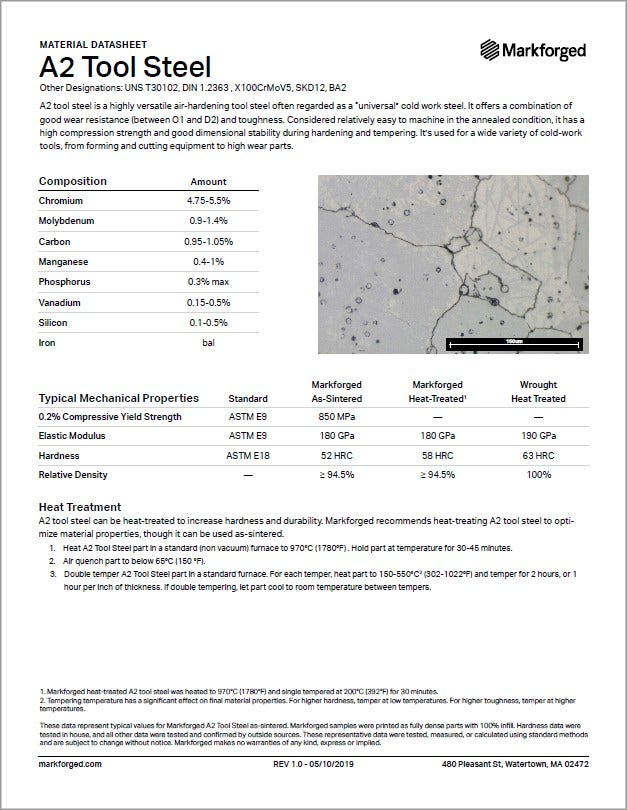

A2 Tool Steel

Similar to H13, A2 Tool Steel is commonly used in a wide range of tooling applications like punches or dies. This particular tool steel has excellent hardness and high resistance to wear. In contrast to H13, this particular steel is a cold work steel. As a cold work material, A2 can be processed without needing to be brought up to temperature.

Click the above illustration to download the Metal X A2 Tool Steel Datasheet.

D2 Tool Steel

D2 Tool Steel is typically associated with having extreme wear resistance properties. In comparison to the tool steels listed above, D2 will hold an edge for longer periods of time, making it excellent for applications such as industrial blades or punches. Like A2, D2 also has excellent hardness and is a cold work steel.

Click the above illustration to download the Metal X D2 Tool Steel Datasheet.

Inconel 625

Inconel is a nickel-based material that is ideal for applications that require high corrosion, chemical or heat resistance properties. Such properties make it ideal for marine or aerospace applications. As is the case with all of the above materials, Metal X users are able to produce parts quickly and in low volume, which is typically pain points when trying to source Inconel parts.

Click the above illustration to download the Metal X Inconel 625 Datasheet.

More to Come

While Markforged has released a significant number of materials for the Metal X in the past few months, they are also working on expanding their current catalog. Materials that are currently being tested for use with the Metal X system include Copper and Titanium. If you would like to review a current road map of metal materials, feel free to do so on the Markforged Materials page.

Check out our website for more information on Markforged and if you have any questions, please feel free to contact us at Hawk Ridge Systems today. Thanks for reading!