Markforged 3D Printers

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

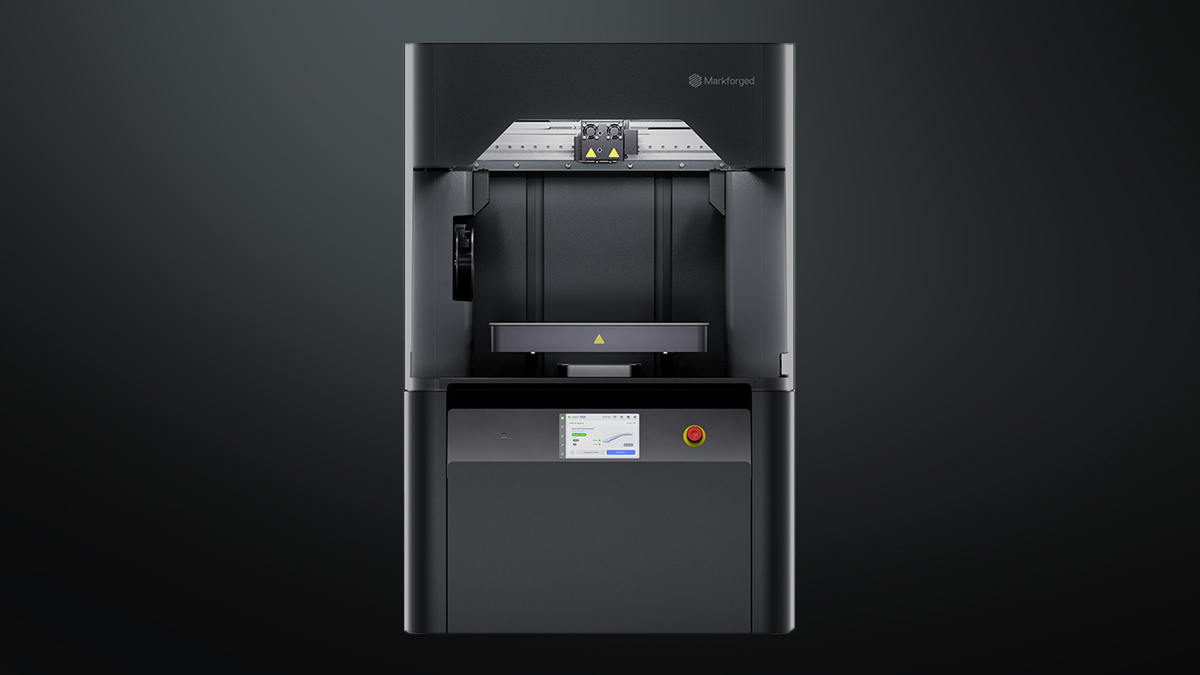

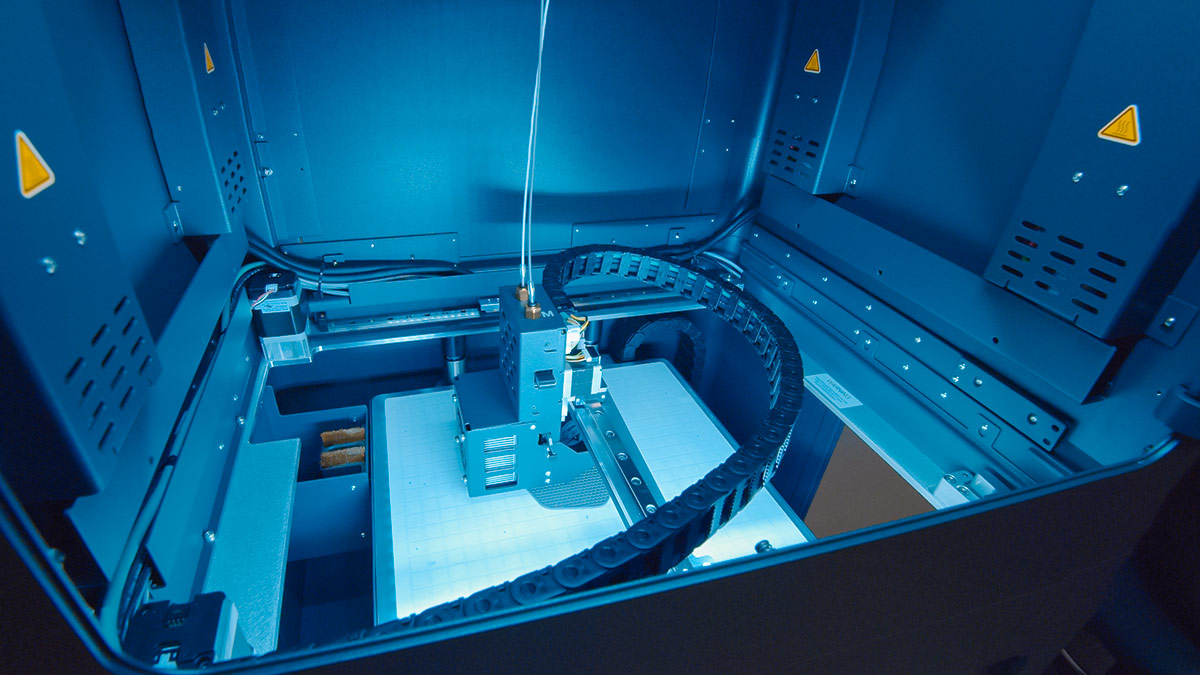

Markforged FX10

Markforged FX20

The Markforged FX20 allows you to create large, robust parts geared for the harshest environments and most demanding industries, including aerospace, defense, or automotive.

Markforged Industrial Printers

The Markforged industrial 3D printers are built tough and deliver industry-leading quality parts at speeds that are impossible with traditional manufacturing methods.

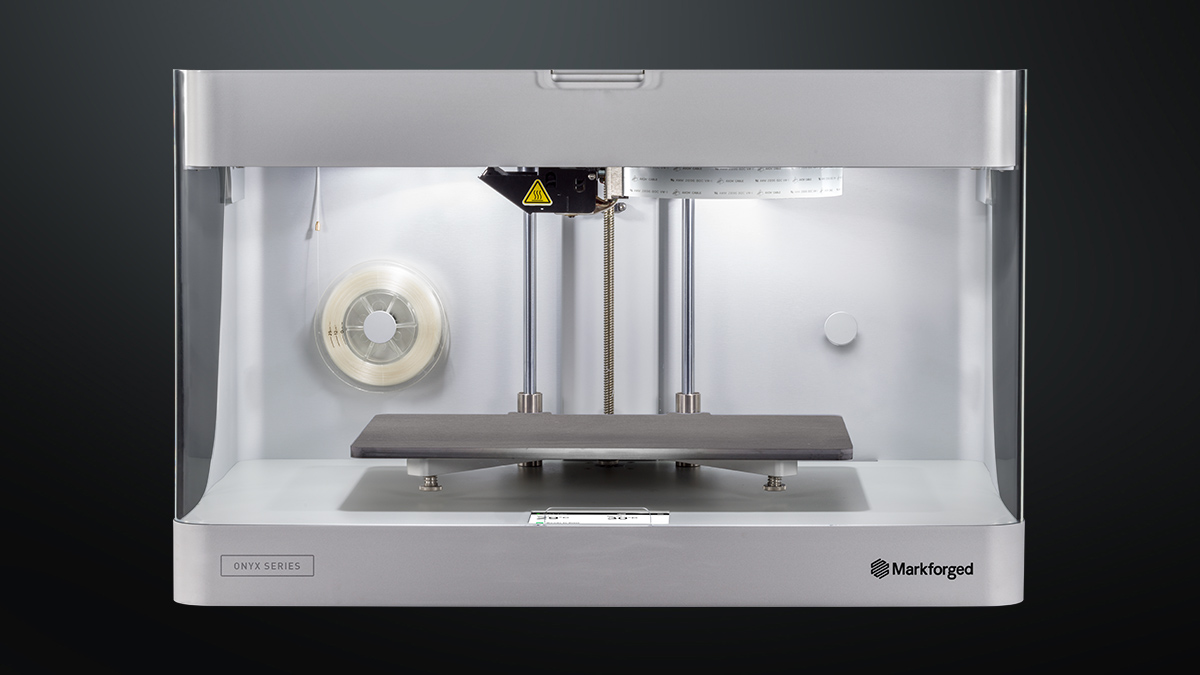

Markforged Desktop Printers

The Markforged desktop 3D printers combine precision hardware, quality materials, and smart technology to give you high quality, strong parts in a small footprint.

Markforged Metal X Printer

The Markforged Metal X 3D printer is a complete additive manufacturing solution for strong metal parts. The system is easy to use and safer than other metal printers.

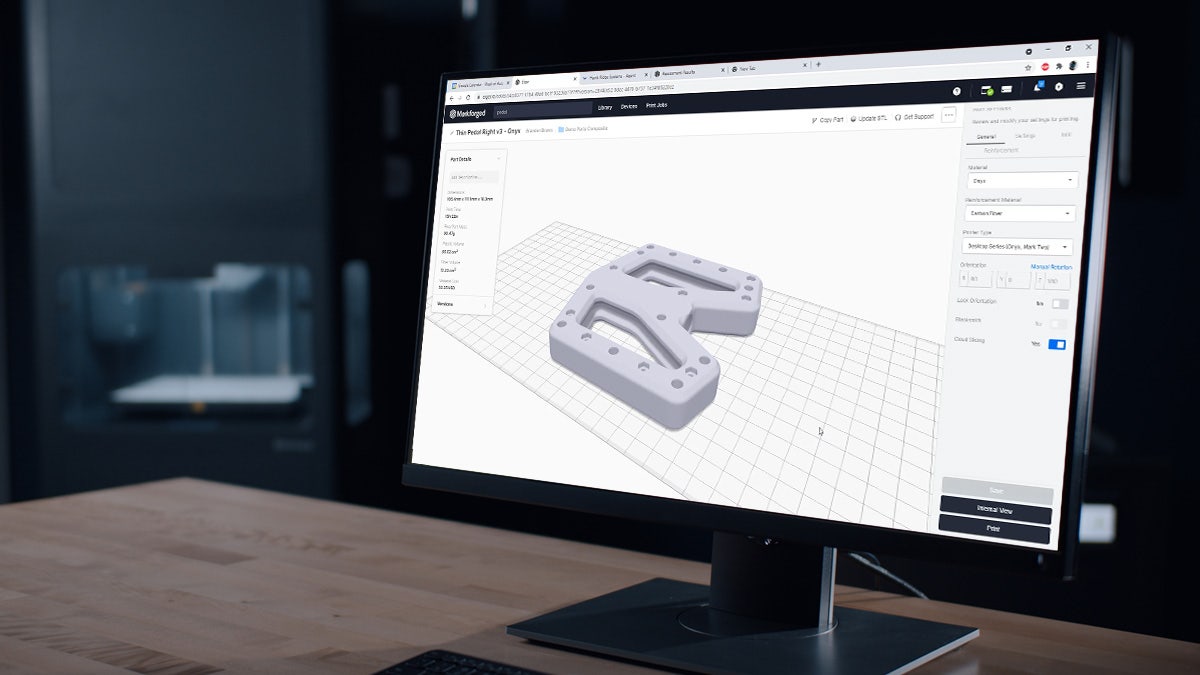

Eiger Software

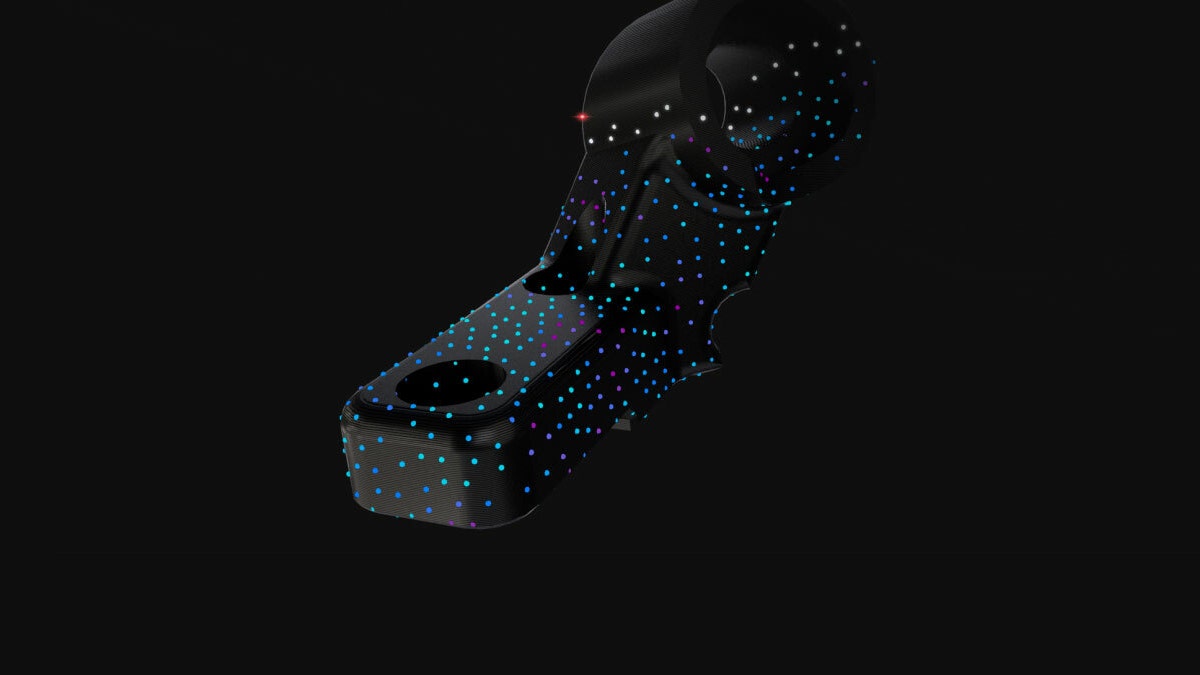

Inspection Software

Materials

Revolutionizing Dragsters With Markforged

In the high-speed, high-stakes world of jet engine drag racing, manufacturing quality parts is a matter of life and death. Just ask Josette Roach, one of only five female jet dragster drivers in the entire world.

Josette Roach and Brian Tocci of Larsen Motorsports saw the need to create a custom steering wheel for Josette’s jet car that would fit her hands exactly. Enter Markforged, and our Simulation software, which allowed the team at Larsen to build this part with top-end accuracy.

Markforged Resources

See It Firsthand: The New Markforged FX20

Watch Live Stream

An Overview of Markforged Materials

Watch Video

Choosing Your Markforged 3D Printer

Download Guide

Launching Careers With Markforged

Watch VideoFrequently Asked Questions

Hawk Ridge Systems has dedicated engineers who operate, install, and service these systems every day. We know the in-depth tips and tricks to truly get the most out of these machines and we help our customers do the same.

Yes, the materials for the Markforged 3D printers are developed, tested, and manufactured by Markforged to create a complete system and designed to ensure your parts meet the quality and performance standards required from a professional 3D printer.

All Markforged systems can run on the free, cloud-based build management software called Eiger. This software is free to try out at eiger.io.

The Metal X uses a 3-step printing process of printing, washing, and finally sintering in an oven. The printing process itself is unique to metal 3D printing because it uses metal powder that is bound in plastic, which eliminates the risks and costs associated with handling metal powders.

Markforged printers have exceptional surface finish at a much higher grade compared to other printing technologies in this space. A major factor is due to the thermoplastics developed by Markforged in combination with finer layer heights.

Yes, Markforged has an offline version of their primary software called Offline Eiger.

Services & Customer Benefits

Technical Support

Unmatched Training

Hawk Ridge offers complete self-paced training programs for the Markforged line of 3D printers. Learn printer operations, how-tos, and best practices when it’s convenient for you.