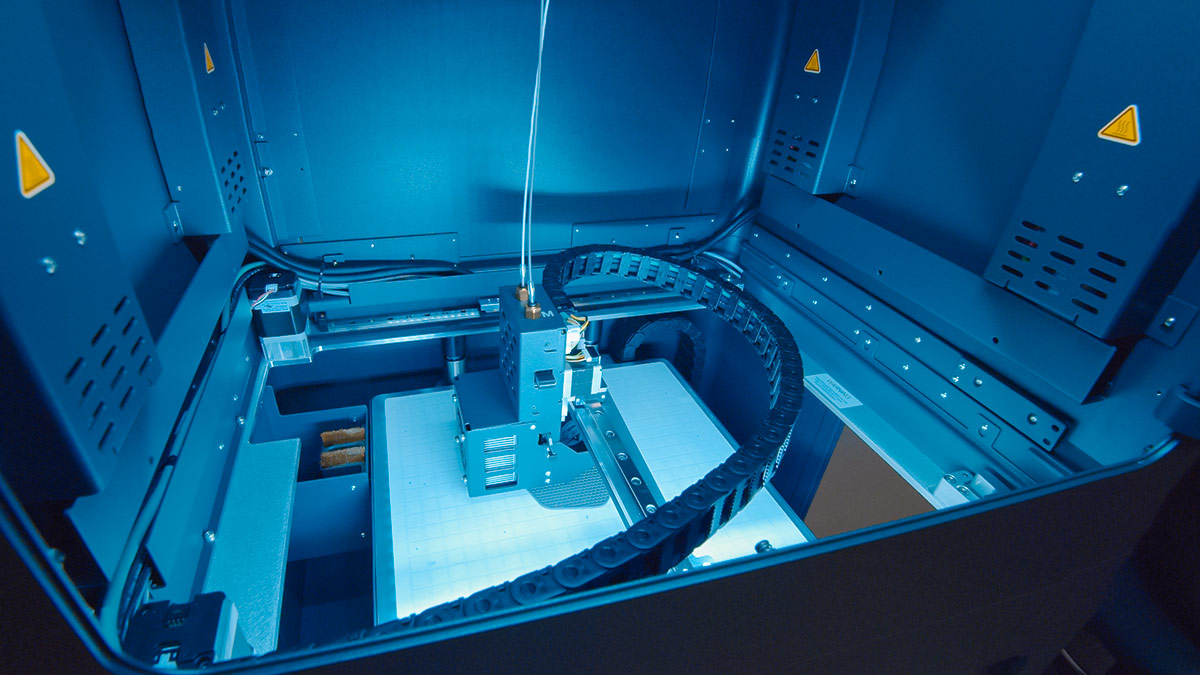

Markforged Metal X Printer

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

The Complete, End-To-End Metal 3D Printing Solution

The Markforged Metal X is the most accessible way to fabricate your complex metal parts in a wide variety of metals. Metal 3D printing is significantly less expensive than tradition methods, like machining or casting, and the Metal X is one of the most affordable machines available.

Unlike traditional powder-based metal 3D printers, the Metal X uses metal powder bound in plastic, eliminating the risks and infrastructure costs related to hazardous powder handling. This makes it perfect for your office or shop and much less expensive to operate. Now you can go from design to fully functional metal parts quickly, safely, and affordably.

Key Features & Benefits

Atomic Diffusion Additive Manufacturing (ADAM)

ADAM is the Metal X 3-step process of printing, washing, and sintering with polymer/wax bound metal filaments.

Eiger Software

Eiger is cloud-based slicing software for sending and managing print jobs for all Markforged printing systems. The software is free to use; sign up and try it today!

Offline Eiger

This offline, subscription-based version of Eiger software for companies that require higher security measures.

17-4 Stainless Steel

This strong, corrosion-resistant material is ideal for most metal printing applications. 17-4 is also the least expensive metal material in the Markforged portfolio.

H13 Tool Steel

This material is harder than 17-4 with a higher heat resistance. H13 hardness rating is 40HRC as-sintered and can be heat treated to obtain a 45HRC rating.

A2 Tool Steel

This very hard and wear-resistant material is great for cold-work forming tools and cutting equipment. The A2 has a hardness rating of 52HRC as-sintered and can be heat treated to obtain a 60HRC rating.

D2 Tool Steel

D2 is the hardest and most wear-resistant material in the Markforged portfolio but less tough than A2 tool steel. D2 has a hardness rating of 54HRC as-sintered and can be heat treated to obtain a 60HRC rating.

Inconel 625

This material is a superalloy that is a highly corrosion-resistant and heat-resistant material perfect for the harshest environments. Inconel maintains an ultimate tensile strength of 500MPa at 600ºC.

Copper

This material with high electrical and thermal conductive properties is great for heat sinks, bus bars, and induction coils. Thermal Conductivity: 350 W/mK. Electrical Conductivity: 84% IACS

Technical Specifications

|

Features

|

Metal X Tech Specs

|

|---|---|

|

Build Volume

|

11.8" x 8.7" x 7.1" (X,Y,Z) 300mm x 220mm x 180mm

|

|

Maximum Part Size (Sinter)

|

Sinter-1: 9.25" x 2.69" x 2.72" (235mm x 68.3mm x 69.2mm)

Sinter-2: 9.25" x 4.85" x 5.56" (235mm x 123.3mm x 141.3mm) |

|

Layer Thickness

|

50 micron, 125 micron (post sintering)

|

|

Machine Size

|

22.6" x 18.4" x 44.1" (X, Y, Z) 575mm x 467mm x 1120mm, 165 lb/80kg

|

Markforged Materials: Strength and Versatility

Discover the robustness and adaptability of Markforged materials. From Onyx for prototypes to Metal X for end-use parts, these materials redefine manufacturing possibilities.

With continuous carbon fiber reinforcement and precision metal components, Markforged empowers businesses to enhance production efficiency without sacrificing quality.

Markforged Resources

Meet the Markforged Metal X

Watch Video

View Markforged Metal X in Your Space

Take a Look

An Overview of Markforged Materials

Watch Video

Choosing Your Markforged 3D Printer

Download GuideFrequently Asked Questions

Yes, you can choose between triangular, gyroid, and solid infill.

The Metal X printer itself does not require ventilation, but the other two machines in the system, the Wash-1 and Sinter-1 or Sinter-2 all require ventilation.

The Sinter-1 is smaller, and does not have stackable seter plates, both of which limit the part size and number of parts you can fit in each run. The Sinter-2, aside from being much larger, also has the ability to do express runs for producing smaller volumes of parts in an expedited timeframe

The Metal X system includes the Metal X 3D printer, the Wash-1, and either the Sinter-1 or Sinter-2.

While this will vary based on print settings, part geometry, and material, the wash process takes around 12 hours, the drying process takes around 4 hours, and the sintering process takes around 27 hours. Keep in mind that multiple parts can be processed per cycle in that time frame.

Yes. To ensure that the bound metal material is printable, both the chamber and the bed of the Metal X are heated.

Yes, both furnaces will consume ultra-high purity argon gas from either a CLC/Dewar or a cylinder multi pack, hydrogen/argon mix gas from cylinders, exhaust filters, and gas supply filters.

No. Unlike other powder-based metal 3d printers, the Metal X uses a polymer and wax bound metal powder which eliminates any hazard that this material might pose.

Services & Customer Benefits

Technical Support

Unmatched Training

Hawk Ridge offers complete self-paced training programs for the Markforged line of 3D printers. Learn printer operations, how-tos, and best practices when it’s convenient for you.