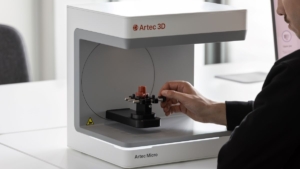

The Artec Micro II 3D scanner takes high-resolution, compact 3D scanning to a new level, bringing even greater precision and ease of use to your desk like many of the easy-to-use portable Artec 3D scanners.

With the Artec Micro II 3D scanner, you’ll enjoy a new camera system with a larger field of view and an improved turntable and full automation. With the click of a button, you can create ultra-accurate scans up to 20 cm in size, with 5-micron resolution, vibrant coloring, and detailed textures.

Read on to learn how this versatile new low-noise Artec 3D model introduces even more precision and ease of use into your work environment — from the jewelry industry to medical institutions.

Capture Realistic 3D Models with Full Color & Texture

The Artec Micro II gives you a deeper depth of data, thanks to its four high-resolution cameras, which capture every edge and minute feature of the part being scanned.

You can capture up to 5 microns in resolution with no compromise on quality. It’s a consistent repeatable factor you can expect from the Artec Micro II.

It’s no problem at all if you need to capture parts up to 20 cm in size. The multi-axis rotating turntable on the Artec Micro II ensures minimal repositioning. A new adjustable fixture plate on the turntable makes it easy to lock parts into position.

Realistic 3D models with full color and texture are generated automatically. You also have the option to use Artec Studio’s photo texturing feature to add high dynamic range textures to achieve the hyperrealism you desire.

Simple to Set Up and Efficient to Use

One of the great things about the Artec Micro II is how much you will appreciate how little space it occupies on your desk’s surface. With its simplified shape and compact size, this scanner neatly integrates into your workflow — almost like it was meant to be there all along.

Plus, it’s low noise and only needs to be calibrated once per month after setup.

You can streamline your scanning process even more with a new Smart Pathing algorithm that turns the Artec Micro II into a one-click machine for high-fidelity 3D scans.

You press a button only once, and the Artec Micro II does the rest, performing thousands of calculations during each scan to ascertain that all faces of the part have been correctly captured in its orientation.

Because no targets are needed, anyone can place a part in the scan space and digitize it. A different part can be swapped in for another scan without the need for any additional preparation. This makes it easy for everyone on your team to use the scanner quickly and efficiently.

Diverse Applications for the Artec Micro II

You’ll find the Artec Micro II has multiple applications across many industries and tasks. Here are some of the applications you can use it for.

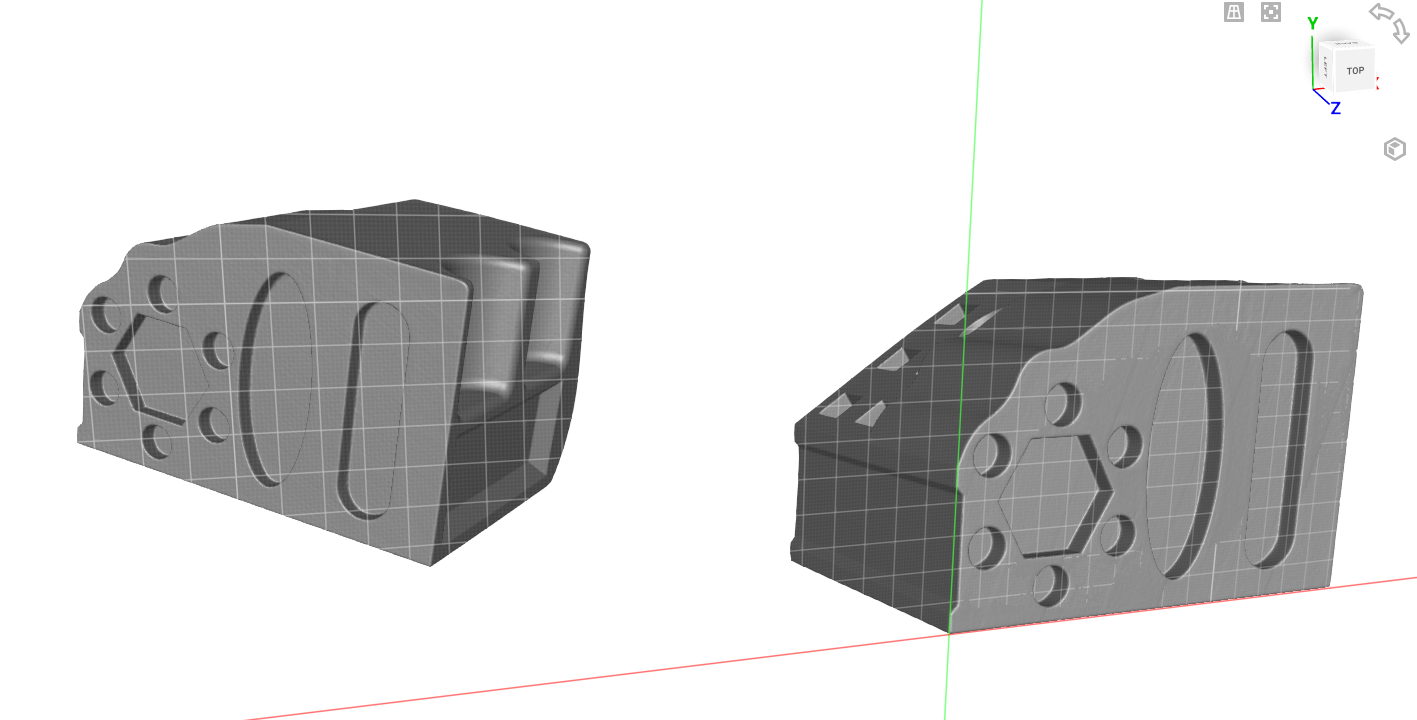

Reverse Engineering

The Artec Micro II was made for reverse engineering. Even the tiniest parts can be imaged in high resolution with super sharp detail, including edges. This model is perfect for replicating legacy parts or changing existing inventory no matter what the industry.

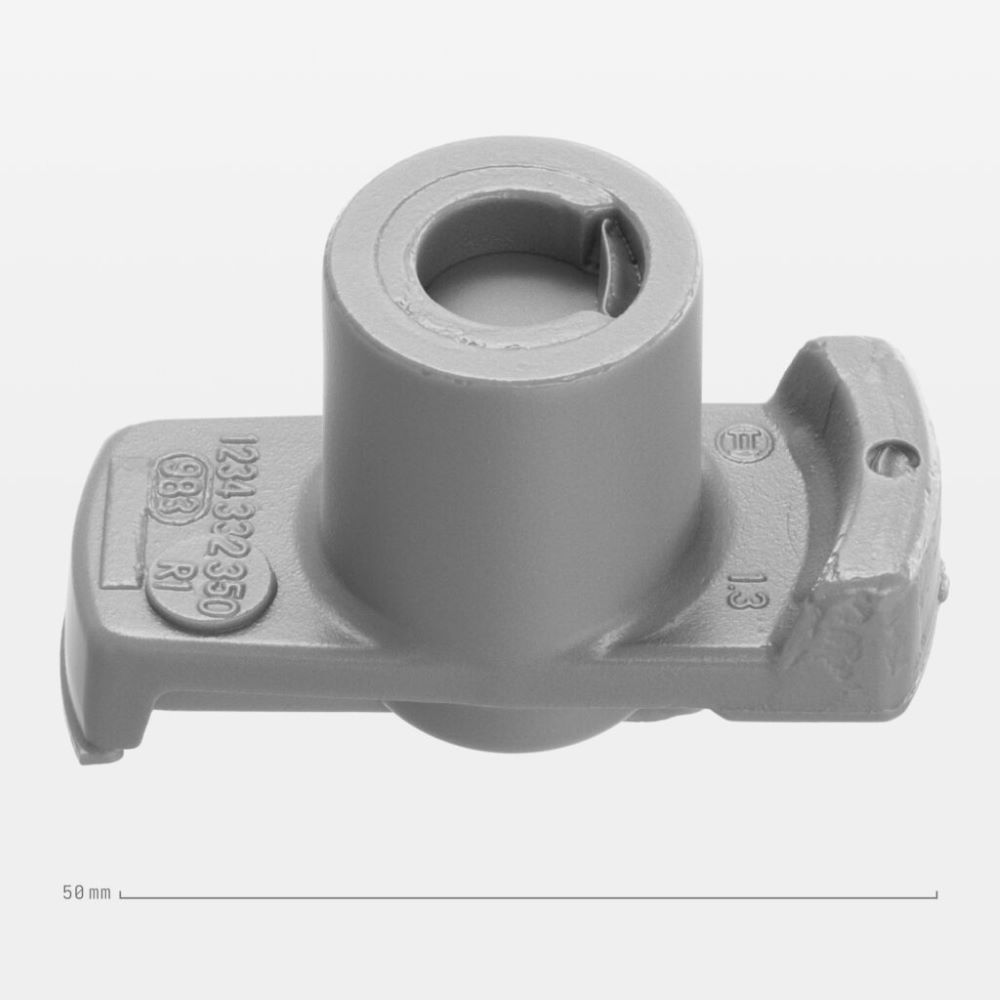

Quality Control

The Artec Micro II gives you ISO certification on accuracy and 5-micron resolution. And you’ll get high-quality meshes for your QI requirements. Like reverse engineering, this ability transcends industries for near universal use.

Medical and Dental

Perhaps nowhere is precision needed more than in medical and dental environments, where scanning is utilized to construct components for the human body. You can use the Artec Micro II to customize devices, molds, and dental implants for the exact fit you need for your patients. Its uses are virtually limitless in this milieu.

Jewelry

Whether you’re a jewelry maker, a museum archivist, or a historian preserving fossils, high-resolution 3D scanning with exceptional detail will enhance your work.

You can capture the smallest jewelry details with the Artec Micro II. And you can scan unique shapes to create future products or reproductions for your collections — ideal for designers and gallery gift shops.

Education and Science

No matter what type of specimen you’re scanning, the Artec Micro II will render it in rich tones and sharp detail using its mega-pixel color cameras. Investigate features, share details with colleagues across the globe, or create a flawless archive with this 3D scanner.

Our Final Take on the Micro II

Regardless of your field, the Artec Micro II gives you a state-of-the-art solution to digitize small parts with the high resolution and accuracy you demand.

The key deliverables the Artec Micro II provides are:

- Attention to detail with color, edges, texture, and shape

- Ability to capture items with 5-micron resolution

- Ease of use free of time-consuming repositioning

- Compact sizing to fit easily on a workplace desktop

- Low noise for the quietest of work environments

- Simple setup with calibration only once monthly

- Consistent repeatability in quality without compromise

With the one-touch workflow, your process will be more efficient while simultaneously achieving finer detail and sharper color matching. If you’ve worked with other desktop 3D scanners, you know how hard it is to accomplish this.

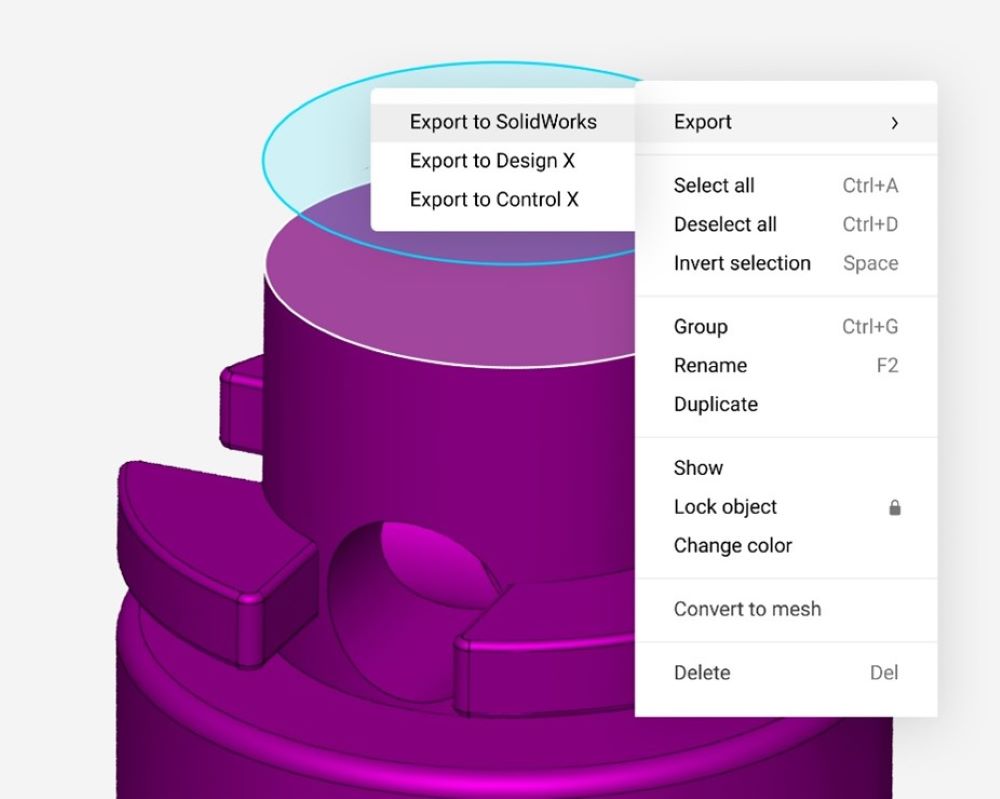

If you’re looking to extract key information and create heatmaps from your 3D scans all within a single software, the Artec Micro II uses Artec Studio 18’s new enhanced processing, 3D scan-to-CAD, and inspection tools.

Ready to go a step further and see how this scanner can revolutionize your unique workflow and results? Speak with one of our experts today. We’re happy to answer any questions you have.