Many industrial equipment designers face challenges with complex product designs. Smart machines have advanced sensing, monitoring, and control capabilities that allow for more automation.

But part of the complexity of intelligent systems, software, and hardware is how to integrate them properly. Designers and engineers have to figure out how each component works and pair it with other parts, such as sensors, microcontrollers, and actuators.

These components can work seamlessly with the right CAD software for electrical and mechanical design elements.

Let’s explore more about these design domains and how to unify them in your product.

What Are ECAD and MCAD Software?

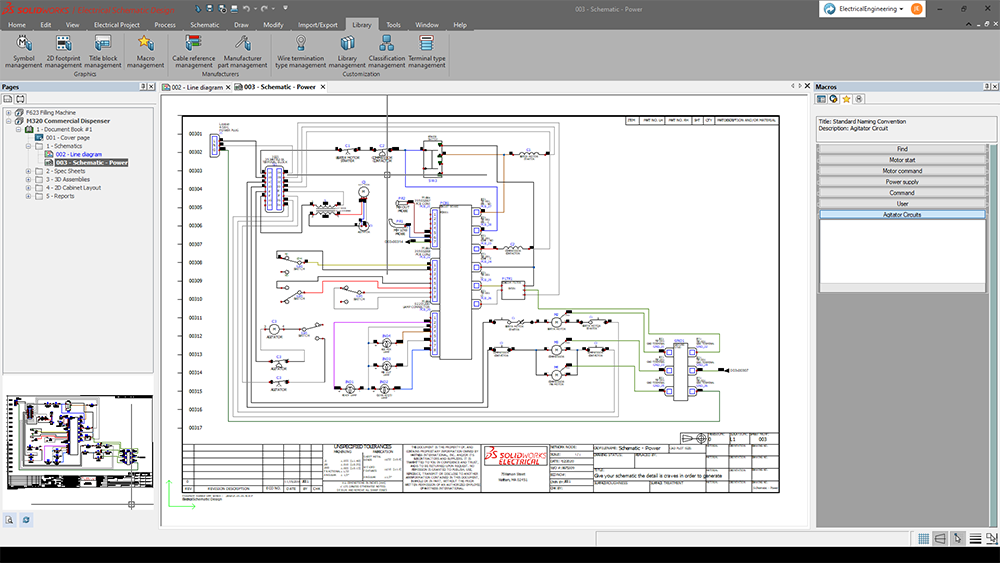

ECAD stands for electronic computer-aided design. ECAD software focuses on creating electronic configurations and frameworks. Designers can build and track electrical schematic circuit designs, including wiring, cables, harness routes, and hydraulic and pneumatic systems.

Many ECAD software programs help electronic designers identify areas with mating board issues, physical part interference, and obstructions, among other capabilities depending on the software package.

MCAD stands for mechanical computer-aided design, and MCAD software concentrates on developing mechanical systems. The software allows designers to construct physical structures and view designs in 2D plans or 3D representations.

MCAD software programs help mechanical designers see gaps or assembly issues in the product. Depending on the software package, simulation tools can test the machine design for any additional structural problems.

What’s the Difference?

Rather than looking at ECAD and MCAD as separate entities, look at them catering to different needs in machine design process. In most cases, you would need both electrical and mechanical designs for machines to function correctly.

That’s why integrating these two domains is a challenge for engineers and designers. Combining ECAD and MCAD elements would require strong collaboration and communication throughout your production process. Otherwise, the machine could break down and malfunction. With both ECAD and MCAD, you’ll have more reliable machine designs.

4 Reasons to Unify Your Complex Design

With the rise of smart machines and AI, complex designs are becoming the new normal. Most often, the challenge with integrating ECAD and MCAD designs is finding the right tool. An integrated tool allows you to work on designs simultaneously and increase product design accuracy.

Here are four reasons to have an integrated design:

- Streamline the design process with one project workflow.

- Increase efficient information sharing across teams.

- Eliminate issues with file exchanges.

- Reduce design revision errors.

Whether you are doing it all or have separate electrical and mechanical teams, you’ll need software that can collaborate with both domains and handle different file formats.

Easier to Start Integrating Than You Think

As a designer and engineer, you might feel you don’t have time to learn new software and be efficient. But it is easier than you think to integrate your ECAD and MCAD tools.

You can integrate several electrical design solutions, such as SOLIDWORKS Electrical Schematic and Enterprise Harness, into the SOLIDWORKS mechanical CAD environment.

With SOLIDWORKS Electrical Schematic, you can automate many repetitive tasks by creating easy electrical layouts. Enterprise Harness can simplify integrating electrical wire harness design into your SOLIDWORKS assemblies.

Because they have an associative link between ECAD and MCAD files, you can change the original SOLIDWORKS CAD file and see the ECAD file automatically update. Real-time version updates help to reduce errors that typically happen with manual revisions.

Evolve with the Market

Industrial equipment designs will continually evolve, and the demand for more automation and customized products will increase. The good news is tools and software will grow with the market. It’s an ideal time to explore how ECAD and MCAD software can enhance your product design process. You can significantly streamline project collaboration and automate repetitive tasks.

If you have any questions about how to integrate your electrical and mechanical design teams, contact us at Hawk Ridge Systems, and we can help you get started.