In reviewing the SOLIDWORKS Manage PLM projects our Hawk Ridge Systems Enterprise Solutions team has been involved in over the last four years, there are many variations:

- Migrations from legacy PLM systems for companies that are already in the SOLIDWORKS CAD ecosystem

- Upgrading from SOLIDWORKS PDM Professional because they needed more functionality

- Moving away from a Windows file system to their first formal data management and PLM system

- A variety of different vertical markets and industries

- A wide array in the amount of data analytics and/or project management they want included in phase one of the project plan (phased implementation vs. big bang)

- And much more

There are two common denominators, however. Most, if not all, of the customer’s primary reasons for looking at SOLIDWORKS Manage included a need for better automation of their bills of materials and engineering change processes.

The Challenge for Enterprise Companies

Large enterprises often have different terms used to refer to their standardization, modernization, automation, and overarching digital transformation corporate initiatives. Similarly, they too often also have slightly varying names to reflect their company’s change processes, requests, corrective actions, and non-conformances, as well as variances as to which departments are involved, when, and exactly how.

They all share a goal, however, of moving away from the as-is system in place that we frequently hear referred to as inefficient or “horrible.” They need to get to a place where they have one optimal system in place across their national or global enterprise for engineering, quality control, operations, manufacturing, project managers, purchasing, marketing, sales, etc.

They are seeking a “gold standard,” if you will, that they can roll out to new departments, global divisions, and newly acquired sister companies with the peace of mind that standardization and centralization tools and processes are central to their foundation.

Time is Money | What is the ROI of PLM?

Time is not just money anymore, it’s a premium. The average hourly burden rates are increasing by the year (or month) now and exponentially more of our workforce is remote. Considering these factors, the industry-standard cost associated with all the steps, and headaches involved with manual change requests from beginning to end, we use a starting point in our Manage PLM ROI calculations is a conservative $3K per request. We then multiply that by how many change requests your company estimates it does over the course a year … over three years.

Curious to see how it looks for your organization and all the other factors involved in calculating an accurate ROI? Please contact us for help. We have developed some great tools that are easy to use and share with other stakeholders.

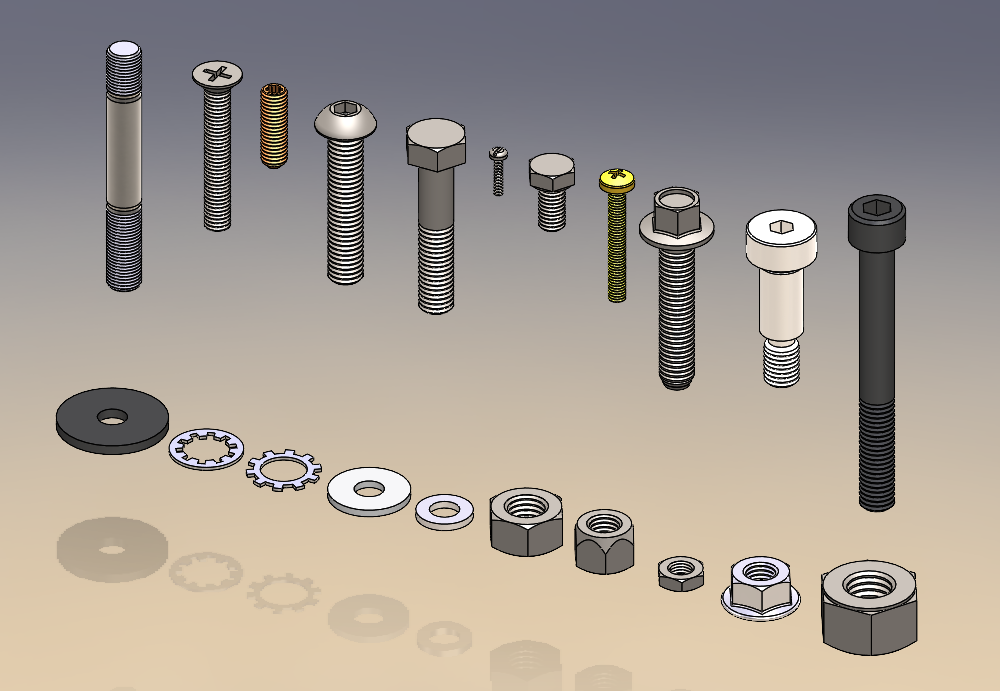

Advanced Bills of Materials

There are several advanced ways to work with bills of materials (BOMs) that our customers have struggled with while using other systems:

- Adding the option of flat BOMs

- Optimally add non-modeled items or phantom BOMs to PLM requirements

- Creating BOMs from multiple data vaults

- Easily comparing different BOM variants and corporate regions

- Pushing it to SOLIDWORKS drawings

- Leveraging any of this data in easily configurable, accurate, and efficient data analytics (dashboards and reports)

- BOM integration to an ERP or MRP system

SOLIDWORKS Manage PLM has an advanced BOM toolkit and starts with an Engineering BOM focus, rather than it being an afterthought.

Learn More About SOLIDWORKS Manage PLM

To learn more about these topics and see how we start to tackle these challenges with SOLIDWORKS Manage PLM, check out our recent webinar, “How to Master Bills of Materials and Changes With SOLIDWORKS Manage PLM.”

Next Steps

The rub on these areas for improvement is that typically when you need these tools and automation most is when you have the least amount of time to explore – let alone implement and train up on. Because of this, you end up defaulting to the path of least resistance: reinventing the wheel with Excel, paper files, manual operations, rework, etc. This, in turn, creates more tribal knowledge and less standardization. What happens when he or she leaves?

It is a vicious cycle that only compounds the issue until the ship changes course or, more aptly, upgrades its engine. Our team has the resources and unique expertise to do a lot of the implementation, configuration, and training heavy lifting on the front end – and even manage all the cloud infrastructure, IT, security, and back-up on Microsoft Azure. That said, it will require a significant investment of time from your team. The sooner you start the process, the sooner you can start to streamline, reduce non-valued added time, and see an ROI. Status quo is always our biggest barrier.

To learn more about SOLIDWORKS Manage and other data management options worth exploring, please contact us at Hawk Ridge Systems today. Thanks for reading!