Many people have questions about the post-processors used in CAM systems, such as:

- What is a post-processor?

- Why are they frequently customized?

- How do you get your post-processor customized?

- How do you change the post you’re using?

We’re going to try to answer many of these common questions in this blog article.

What is a Post-Processor?

Simply put, a post-processor (or post) converts the tool paths we make in CAM tools like SOLIDWORKS CAM or CAMWorks into a specific output format your machine can understand. This output, called G & M codes (or NC code), is really just a well-formatted text file that is specific to your machine and how you want to run it. Another way to think of a post- processor is like a driver you might install after picking up a new graphics card. The driver ensures your new card can communicate properly with your computer and work correctly.

You’ll definitely want to start with a post built for the machine or controller you’re using. Both SOLIDWORKS CAM and CAMWorks come with several posts but you can download many more machine-specific posts for free from our CAM post-processors page. These posts are great for 2.5 axis milling and turning but at some point, machinists will want to do more.

For example, we may want to:

- Modify the code output to match the parameter setting in the controller

- Add probing options

- Introduce different types of coolant control

- Add a custom header to the file including the programmer’s name

- Bring the machine table to the front center at the end of the program so the parts can be more easily unloaded

Post-processors are a critical part of your CAM and CNC tool set, and without the right post the machine may not run properly or to its full potential. Get it wrong and your machine may not cut the part or worse yet, do something foolish like run the spindle into the table or chuck (which gets expensive quickly). Get it right and it will bridge the gap between what you programmed and your machines’ full capabilities.

Creating and Customizing Post-Processors

The most common way to get a post customized for your machine and the way you run it is to have us do it for you. We have an amazing team with over 100 years of combined machining experience. Our post writers are the best in the business, and we work closely with our customers and machine manufacturers to find the best way to accomplish your goals. Because we’re writing posts every day we’ll help you avoid common pitfalls and leverage our extensive experience to capture the best way to accomplish your goals.

Another option is to create a post yourself using the free universal post editor, and you can learn more about how to use that from our blog on writing post-processors with CAMWorks.

When running any new post, it’s good practice to test them thoroughly, as the consequences of mistakes and unforeseen issues can be expensive. Be sure to do a dry run without stock or coolant, to test any changes you make, rather than just hitting the green button and walking away.

Changing Your Posts

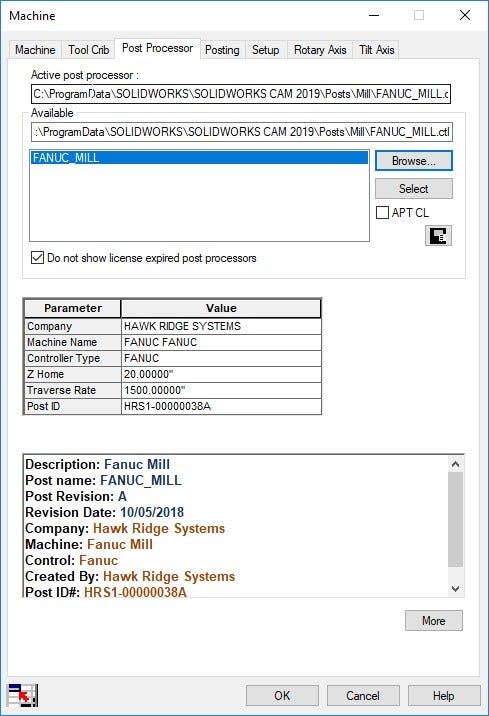

The last thing you need to know about posts is how to change them. From the SOLIDWORKS CAM or CAMWorks feature tree, right-click or double click the Machine and edit the definition. Now choose the Post-Processor tab at the top and you’ll find a browser button that will let you select the new post.

Posts (including the free ones on our website) can unlock hidden features, so be sure to review the new options available in the setups, operation parameters and machine areas after changing posts.

Do you have any other questions about CAM post-processors? Let us know in the comments.

Check out our website for more information on SOLIDWORKS CAM or CAMWorks. If there’s anything we can help you with, contact us at Hawk Ridge Systems today. Thanks for reading!