The industrial equipment industry has been growing with many innovative machine designs for today’s consumer market. Yet, one industry challenge is how to best communicate and collaborate on projects from design to manufacturing.

Without strong communication and collaboration on your product designs, you could face delays and cost your company money.

Let’s explore two types of product management tools – product data management (PDM) software and product lifecycle management (PLM) software – you can use on industrial equipment designs.

How a Lack of Communication Affects You

As an industrial equipment designer, you work closely with many stakeholders, including design engineers, production teams, suppliers, and clients. A breakdown in your communication can cause slowdowns or even failures in large-scale projects. You may even see a decline in revenue or spend money trying to resolve the issue.

And if you work for a worldwide company, these challenges can become massive. You may already juggle multiple design centers or plants, countries, and time zones. So, it can be even more challenging to halt production because of miscommunication.

2 Types of Software to Improve Your Product Design Collaboration

Many checkpoints and collaborative manufacturing conversations need to happen before, during, and after your project is in motion. It helps to look into how your product designs move from ideation to execution and understand where you can improve. Here are two ways you can streamline your communication and collaboration efforts.

1. Using Product Data Management (PDM) Software

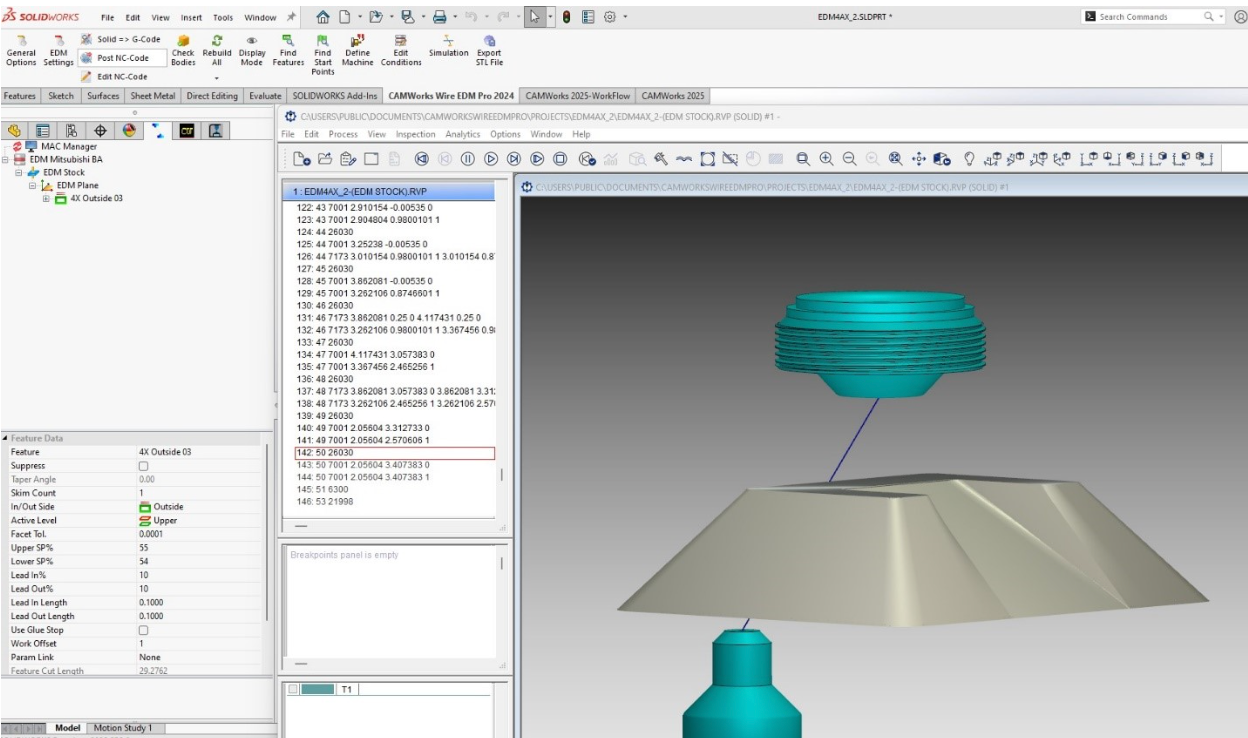

PDM software can help organize information associated with your product design, from initial concept to final design and manufacturing.

You can easily share knowledge between dispersed teams nationally and globally, keep track of innovation and efficiency throughout your development cycle, and track project changes.

Data management systems can also store and manage large files associated with design, including 2D/3D CAD models, images, videos, bills of materials, and production files.

If you’re in a position that makes sense to restrict access to other job roles, you can do so with access control. Controlling access can ensure different teams and stakeholders only access project information that is relevant to their position. Access management can help avoid confusion or unnecessary delays and increase collaboration among team members.

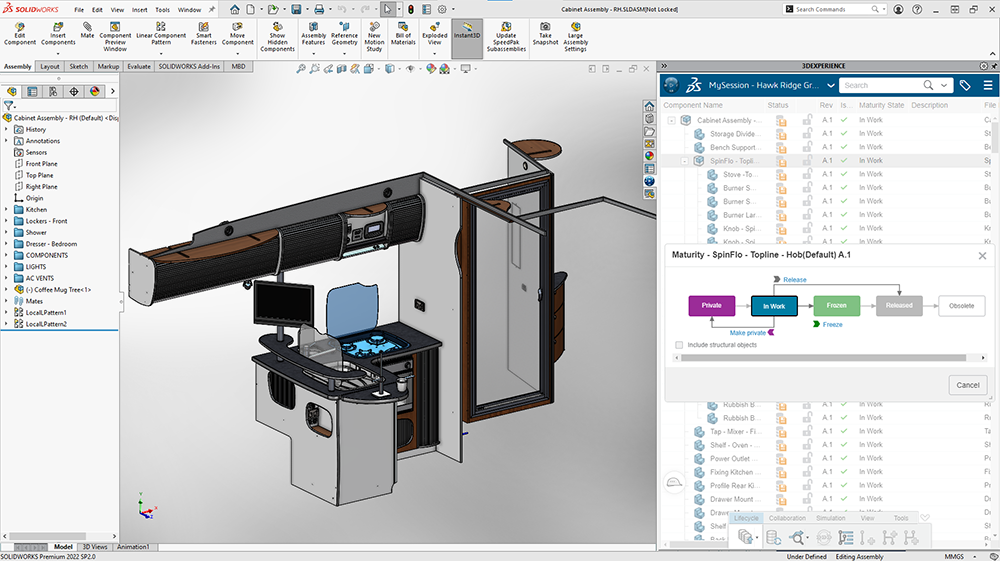

SOLIDWORKS PDM and data management tools on the 3DEXPERIENCE platform are two PDM options that help industrial equipment and heavy machinery companies understand their workflows. They also provide practical ways for teams to work remotely with individuals and engineering groups in the U.S. and overseas.

Here are their key benefits:

- SOLIDWORKS PDM helps design teams improve their workflows and how they store and work with data. Using PDM, you can:

- Securely store data so it is never lost.

- Manage version control to ensure engineers across teams work on the file’s current version.

- Automate processes, including approvals and engineering change orders.

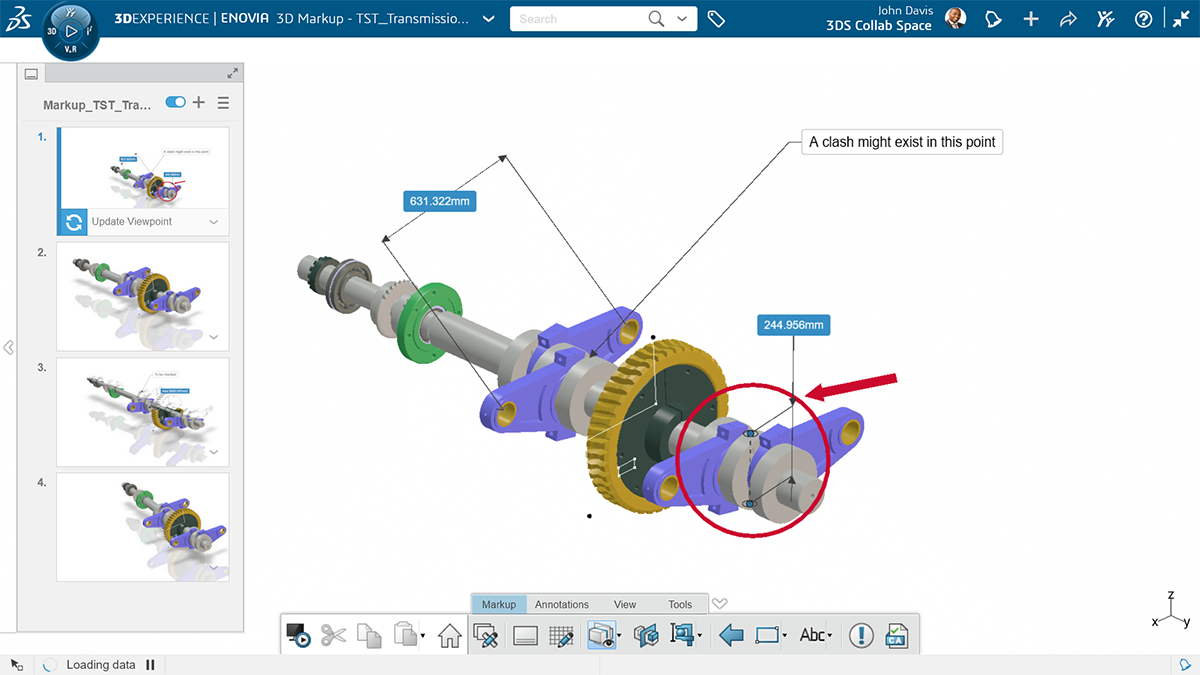

- Data management tools on the 3DEXPERIENCE platform are secure, scalable, cloud-based data management and collaboration tools for internal and external stakeholders. You can:

- Access data from anywhere on any web-enabled device.

- Securely share data and files with anyone for review and feedback.

- Have constant communication and feedback from customers throughout the design process.

2. Using Product Lifecycle Management (PLM) Software

Effective PLM software can break down complex projects into bite-sized stages. From there, you can define tasks and assign them to specific team members with detailed instructions and deadlines.

These types of software can monitor progress, identify roadblocks, and automatically communicate updates to project owners and key individuals. You can get quick status updates on each stage of your production process.

PLM tools incorporate data analysis techniques, such as machine learning and AI, to help you identify areas that need development and evaluate your product design progress smarter.

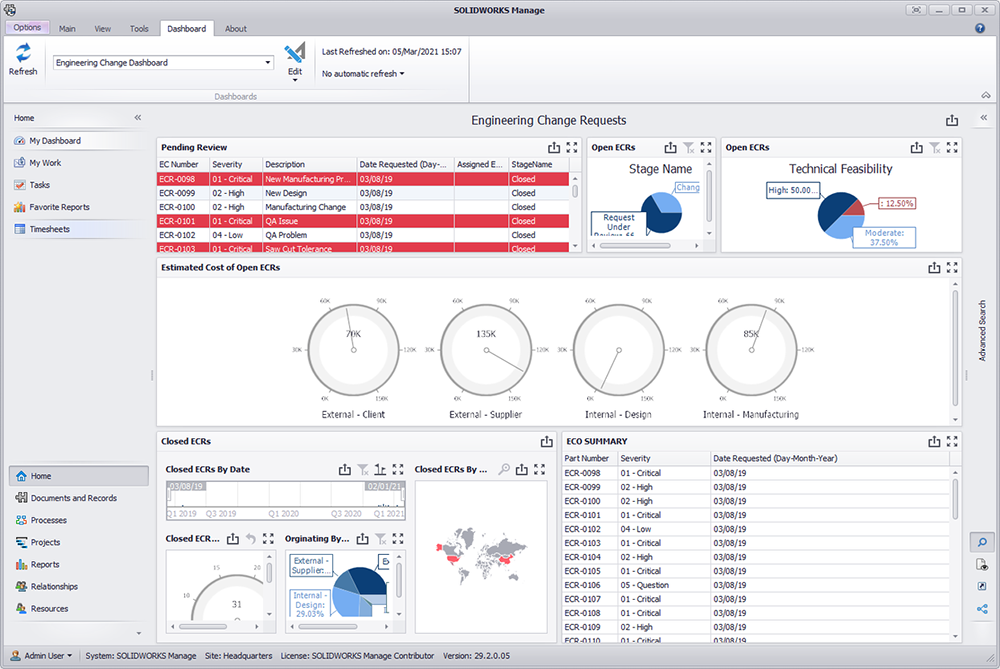

SOLIDWORKS Manage is a PLM tool. It gives you a bird’s-eye view of your design’s status, advanced data, and product lifecycle. Here are a few key features and benefits:

- Project management options to track stages, timelines, resource utilization, tasks, milestones, and progress of product development projects.

- Process management opportunities, including automation and the ability to configure states and decision points for a range of processes.

- Item management for advanced capabilities when it comes to creating, editing, and comparing bills of materials.

- Comprehensive dashboards and reporting features for key stakeholder visibility.

On Your Way to Simply Innovating

Your design data can be manageable. To start, you’ll need to explore how you and your team communicate and collaborate during your design-to-manufacturing process. Then you can understand how to organize your data, tasks, and project’s lifecycle journey. Once you do all that, you can finally concentrate on the fun part – innovating!

If you have any questions or want to see how SOLIDWORKS PDM, data management tools on the 3DEXPERIENCE platform, and SOLIDWORKS Manage can work for you, contact us at Hawk Ridge Systems.

You can also read more about which SOLIDWORKS data management tool is best for you.