About Alien Machine Worx

Alien Machine Worx is a family-owned American company dedicated to manufacturing parts with the highest quality. They machine custom parts and components for the off-roading automotive aftermarket such as rear differentials, manifolds, and grip bars. They are committed to providing superior automotive parts for off-road drivers worldwide. We sat down with -Blake Fulton, the current owner at Alien Machine Worx to learn more about how they use SOLIDWORKS and CNC machining to build.

Creating Aftermarket Custom Differentials with SOLIDWORKS

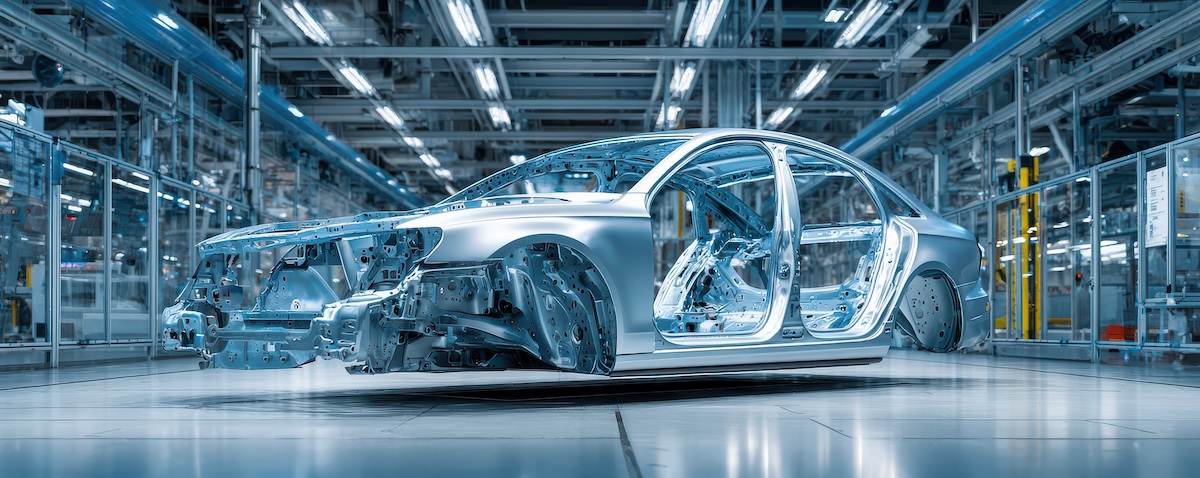

Alien Machine Worx is known for their custom high-strength differential covers for off-road vehicles. They used SOLIDWORKS Simulation, CAMWorks, and SOLIDWORKS to design and test this custom design with added ribs for extra durability against rocks and damage.

But that’s not all they do (just what they’re well-known for.) Their customers actually range from hospital labs to off-road vehicles to parts for solar panels to old vintage cars.

They handle customer ideas from concept to production, including drawing parts, programming tool paths, and running machines.

“Stock covers that most vehicles come with are usually just a thin piece of sheet metal and they’re easy to puncture. If you hit a rock or something, they pin the crack or dent very easily. Ours is made out of aluminum and they are half inch thick all the way around so they’re much stronger. The ribs that run down the side of our dish covers add another extra layer protection a half-inch thick on top of it.” –Blake Fulton, Owner at Alien Machine Worx

They also collaborate with companies like RPG Off-Road for differential covers, specifically for the Ford Raptor.

“Those are the coolest parts we make (so far), and they have our logo on them so that’s even cooler.” -Blake Fulton, Owner at Alien Machine Worx

How They Use SOLIDWORKS and Other Tools to Create Automotive Aftermarket Parts

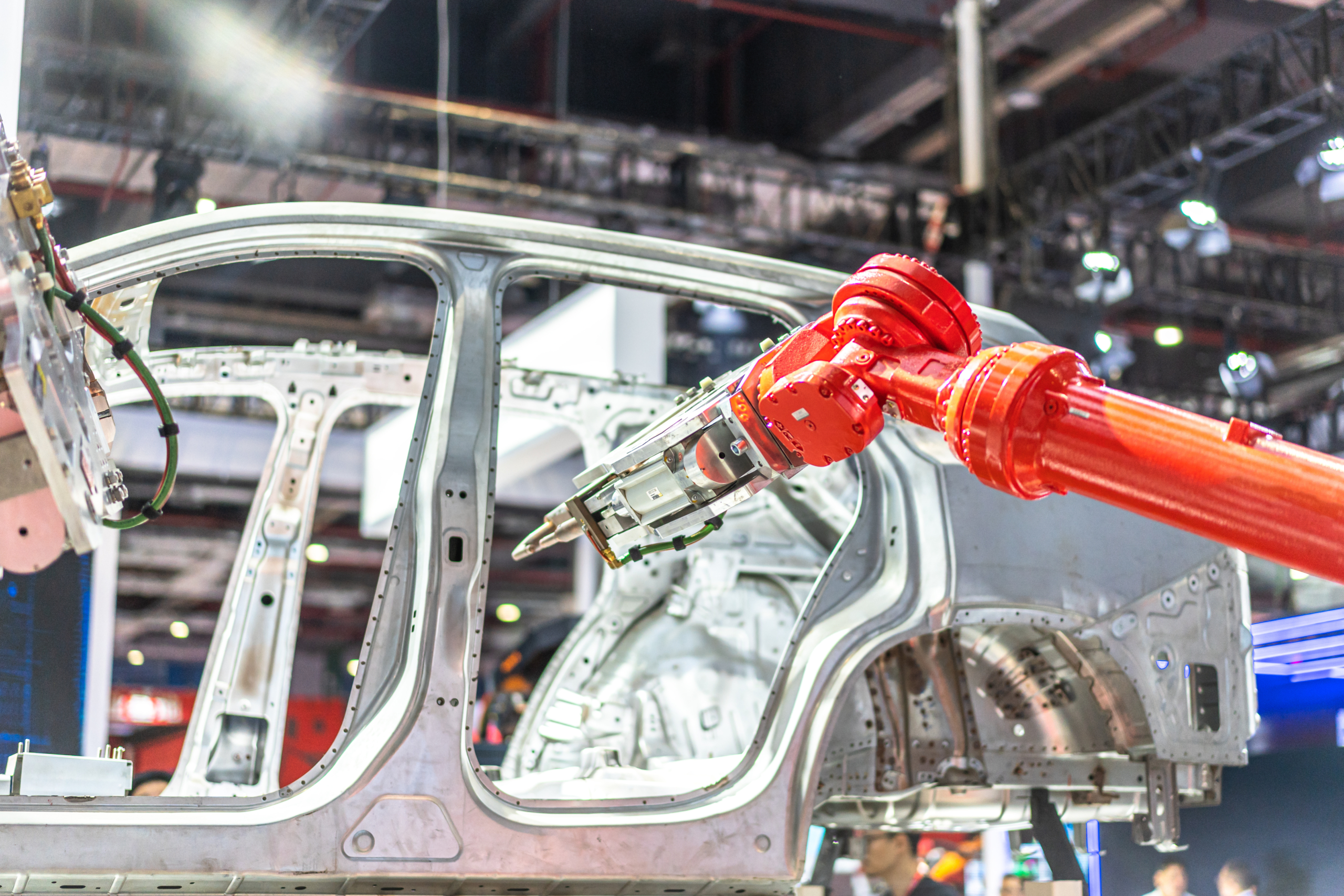

Alien Machine Worx uses SOLIDWORKS for prototyping and design (e.g., drawing customer ideas, showing 3D models), and CAMWorks for programming tool paths to run machines.

They use a combination of machines with both older and new electronics, a Fadal mill (their favorite for sturdiness), and a hot lathe. They also have 3D printers in-house for printing custom parts.

For them, SOLIDWORKS enables quick prototyping, strength testing, and efficient production. The software is straight-forward, and if they ever have an issue, they just pick up the phone and call Hawk Ridge Systems for help. Alien Machine Worx has a unique relationship with Hawk Ridge Systems. Tim Fulton, who started Alien Machine Works, actually used to work at Hawk Ridge Systems as a Sales Territory Manager, so when it came time to grab SOLIDWORKS licenses, it was the perfect fit.

What’s Next for Alien Machine Worx?

AMW has ambitious growth plans, including expansion to a larger facility, adding more machines, and shifting from a job shop to their own line. They also are leveraging AURA AI in SOLIDWORKS for faster design, finding it helpful to quickly find commands and information within the platform more easily.

Currently, they’re finalizing a new off-road rim prototype before market launch.

“We’re hoping to grow bigger get more machines get a building and start doing more of our own product.” -Blake Fulton, Owner at Alien Machine Worx

If you want to learn more about Alien Machine Worx, check out their website and follow them on social media: Alien Machine Worx on Instagram and Facebook.