About Pacific Recycling Inc.

Founded in 1985, Pacific Recycling Inc. is Southern Oregon’s largest scrap-metal recycler, featuring heavy equipment to sort and recycle materials, including a 4,000-horsepower state-of-the-art automobile shredder.

Pacific Recycling Inc. Mission & What They Do

Pacific Recycling Inc. processes over 200 million pounds of recyclable metals annually, supplying local and global manufacturing industries with sustainably sourced raw materials for new buildings, bridges, cars, and other essential items. The reclaimed materials contribute to the production of new materials like steel (70% of U.S. steel comes from recycled sources), aluminum, copper, and more, while reducing environmental impacts such as greenhouse gas emissions and landfill waste.

Notable impacts:

- Reduces ecological and other environmental harm caused by mining for raw materials

- Reduces greenhouse gas emissions from extraction, transport, and refinement of virgin materials

- Less waste sent to landfills

- Cleaner, greener manufacturing processes

- Sustainable supply chains for essential goods and infrastructure

Challenges

To support their metal material recycling mission, Pacific Recycling Inc. is always trying to increase and optimize the quantity of recyclable materials recovered, reduce costs for parts, optimize maintenance, repair, and operations, improve plant layout, and future-proof their equipment, facility, and operations.

“When you recycle things, you never reclaim 100% of all the good material that you want to reclaim. You always miss a little bit. And the technology is always improving. We are constantly seeking out incremental improvements, leveraging lean manufacturing techniques and practices.” –Chuck Burgess, Shredder Engineer at Pacific Recycling Inc

Key Challenges:

- Increase quantity of recyclable materials recovered

- Improving and growing predictive maintenance which decreases downtime

- Add efficiency to workflows

- Increase throughput of equipment

- Optimize plant layout through strategic equipment upgrades

- Reduce time to implementation by using robust simulation and creative prototyping tools

“Everything is big, heavy, and expensive. If I could change one thing tomorrow, I would make everything lighter! But seriously, since we cannot change gravity, we just have do a better job planning around it. We focus on simulating and prototyping tasks and tools. This lets us work safely and allows for rapid iteration on incremental improvements. A lot of what I do is trying to imagine a way of doing something, describe it, and get buy-in from the team.” –Chuck Burgess, Shredder Engineer at Pacific Recycling Inc

How They Use SOLIDWORKS and Other Tools for MRO & Process Improvement Projects

Every time PRI opens up SOLIDWORKS, they are leveraging lean methodology to make improvements that lead to more efficient material recovery and doing more with less. The scope of their SOLIDWORKS projects includes things like coming up with new designs for key components in equipment, using modifications to squeeze more life out of existing equipment, and finding solutionsfor recurring issues.

Key Wins

Conveyor Belt Edge Repair Patch: They developed and modeled a patch repair process in SOLIDWORKS CAD for damaged belt edges, extending belt life by months, which costs about $30 per patch versus $5,000–$6,000 for a full belt replacement. They also saved some time, going from 1 hour for the patch versus a full day for the belt replacement.

“The conveyors have these very large like ribbon-like belts, and the edges like to tear where the ends of the belt are joined together. When it gets worn there, we had to replace them. We came up with this new way of patching it so that we don’t have to replace the whole belt immediately. Instead of an unexpected down day to replace a belt we can be back up and running in an hour and schedule a belt replacement when it is convenient for us to do so.” –Chuck Burgess, Shredder Engineer at Pacific Recycling Inc

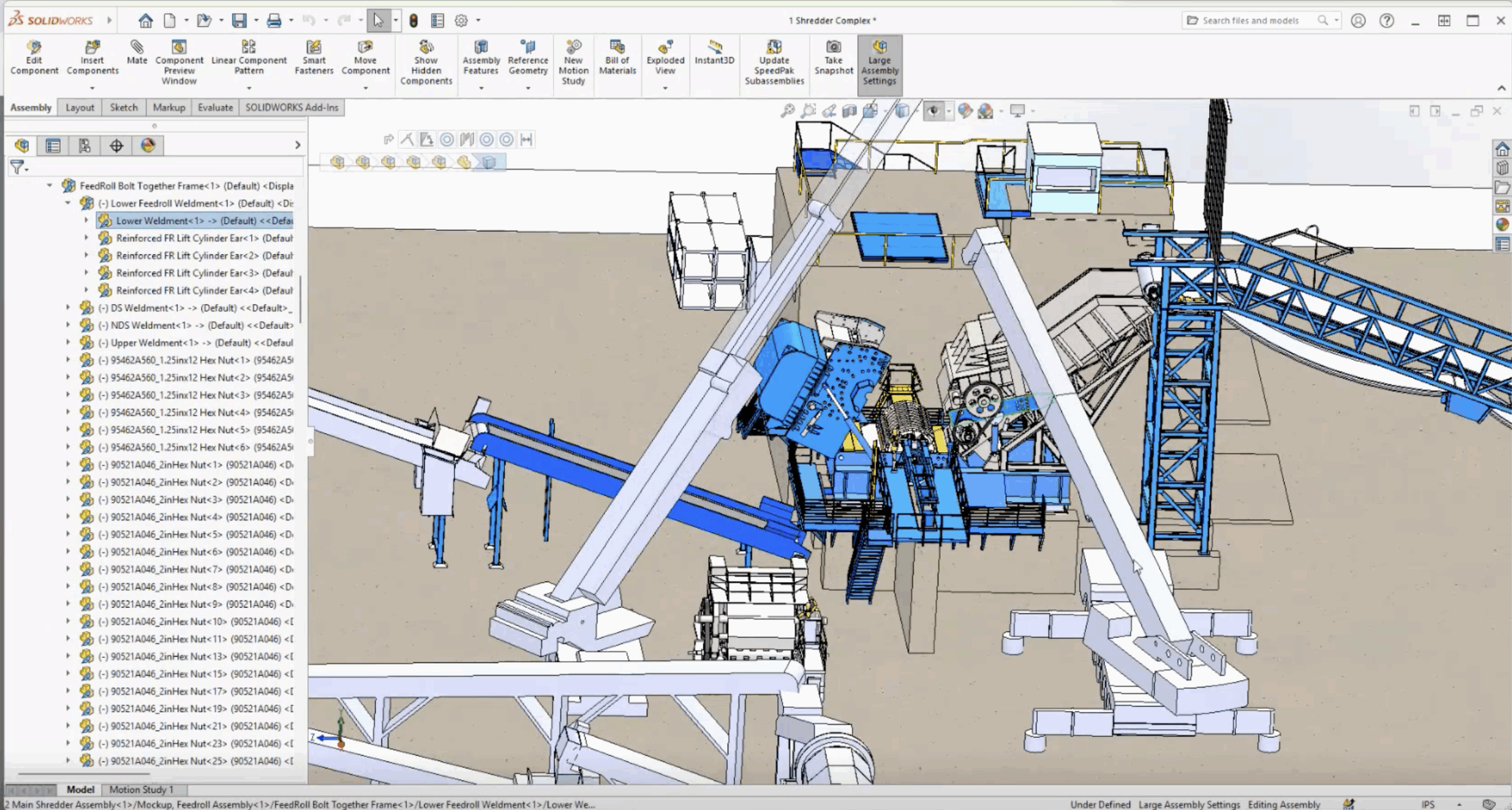

Feed Rolls Removal Planning: They used SOLIDWORKS CAD layouts and equipment mock-ups to plan the removal of major components such as Feed Rolls, which are used to push cars into the Shredder. This ensures accessibility for people and vendors and confirms it fits in designated landing areas to avoid hiccups during execution.

“I’m having to plan through how we’re going to remove a major component. We call these the feed rolls. I’ve made mock-ups of the cranes we intend on renting, and I’m planning out where the crane operator will need to land the object and whether or not it will be accessible to people and vendors to reach critical components. Instead of just saying, well, we can probably fit it over here, I make an envelope model and put it out there and say yes, I feel confident if we put it right here. The human models really help. It’s also much easier to explain what I plan on doing by showing someone.” –Chuck Burgess, Shredder Engineer at Pacific Recycling Inc

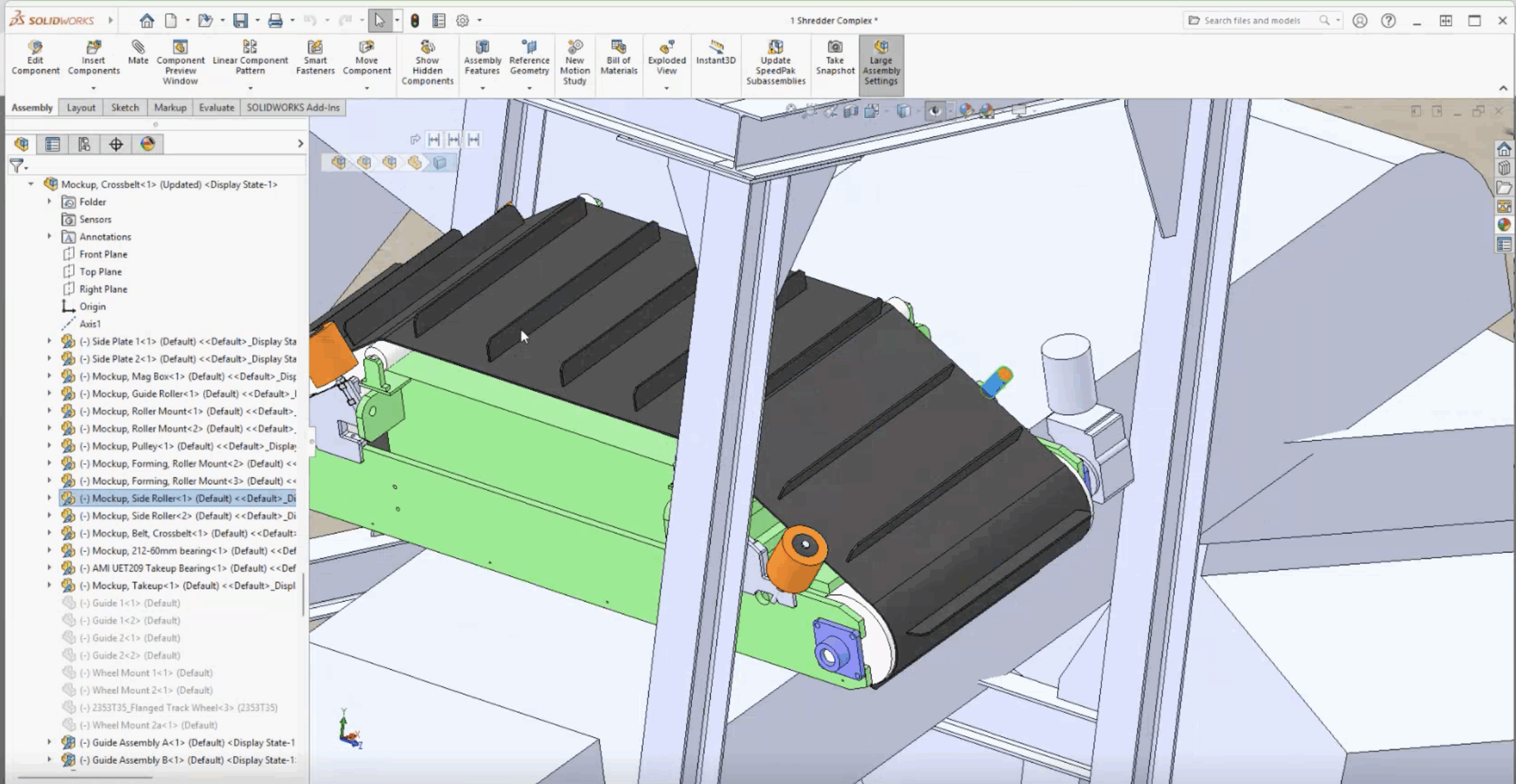

Cross-Belt Conveyor Bracket and Roller Redesign: Redesigned a bracket and roller system in SOLIDWORKS to fix frequent breakdowns and tracking issues on the conveyor, resulting in stable operation without daily adjustments until the belt naturally wore out.

“This is a cross-belt conveyor, and the manufacturer sells it with these little tiny guide pulleys. And this thing breaks down very often, and we could never guide it. I used SOLIDWORKS to come up with a new bracket design, and we were able to keep it running longer.” –Chuck Burgess, Shredder Engineer at Pacific Recycling Inc

Those are just three examples of how Pacific Recycling Inc. uses SOLIDWORKS to reduce downtime and improve operations, but there’s a ton more going on behind the scenes. They’re also using 3D-printed models for hands-on planning exercises and training. They use LiDAR sensor in the iPhone Pro to make 3D scans to incorporate details like ductwork and conduits into 3D models as well as for gathering measurements quickly.

Examples:

3D Printed Model of Critical Machine: They created a 3D printed model of the three-story shredder machine (including moving parts like rotors and hammers!) using SOLIDWORKS and 3D printing. These types of models are then used for hands-on planning of complex tasks like rotor lifting and for training new hires on machine operations.

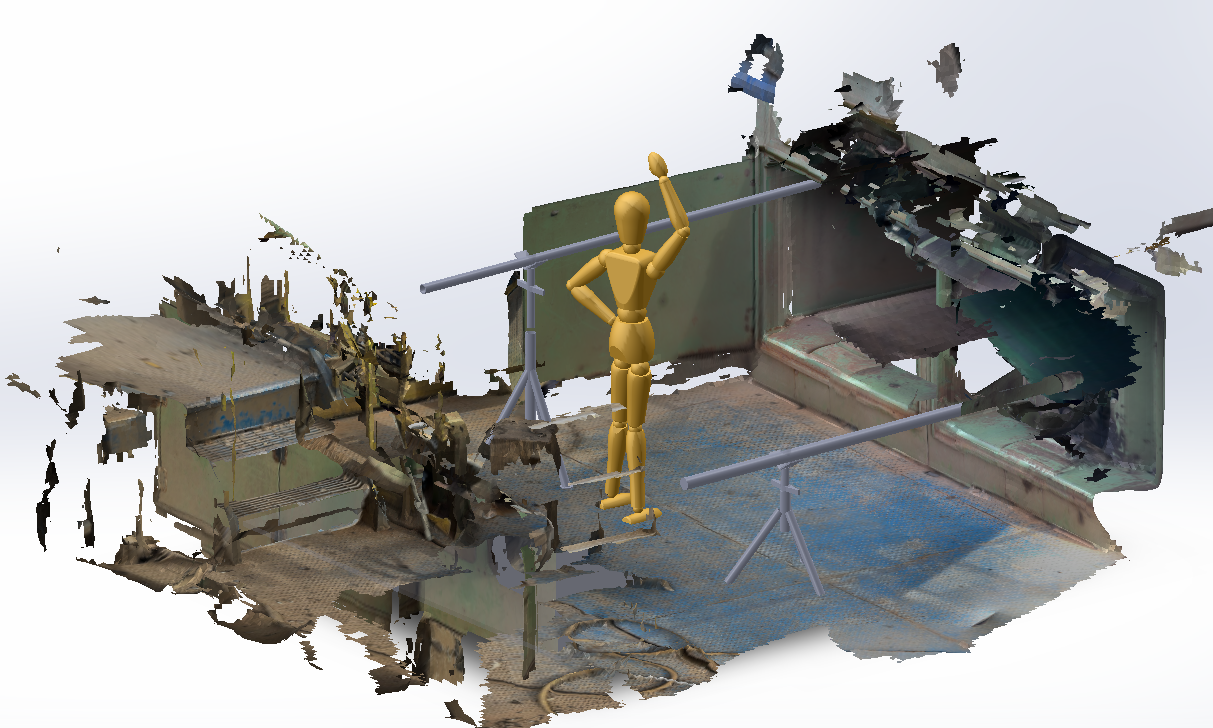

Room Scanning for Project Planning: They use cell phone scans imported into SOLIDWORKS as OBJ files to create overlaid 3D models of rooms, capturing details like ductwork, conduits, and tools for accurate planning of lifts and equipment fits, reducing missed measurements and back-and-forth.

Why Hawk Ridge and Why SOLIDWORKS?

Previously, Pacific Recycling Inc. used a very different CAD program, which was limited in use. Their Shredder Engineer, Chuck Burgess, with experience as an engineer at companies like Arcimoto, Blue Origin, Genie (a Terex brand), and Omax Corporation, made the case to upgrade to SOLIDWORKS.

“I had used Hawk Ridge previously when I first worked at Genie Industries for CAD training, so I was very impressed. I took some of their FEA classes and had a very good experience. And anytime I’ve had a technical question with Hawk Ridge, I don’t know how you guys do it, but you always have the answer.” –Chuck Burgess, Shredder Engineer at Pacific Recycling Inc

“SolidWorks is a wonderful way for me to model and express my ideas and plan things out and check things.” –Chuck Burgess, Shredder Engineer at Pacific Recycling Inc

What’s Next for Pacific Recycling Inc.?

These are some key future state objectives:

- Optimizing designs with new geometry

- Future plant improvements

- New equipment upgrades and purchases

- Exploring the use of automated recognition with sensors to recoup more materials

Examples:

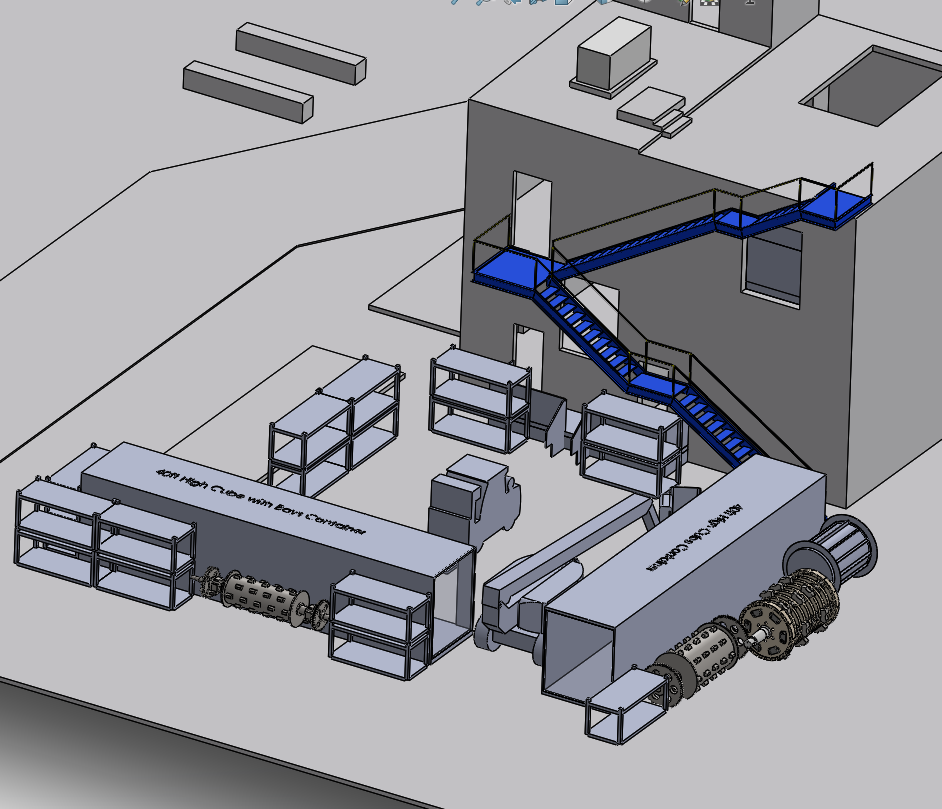

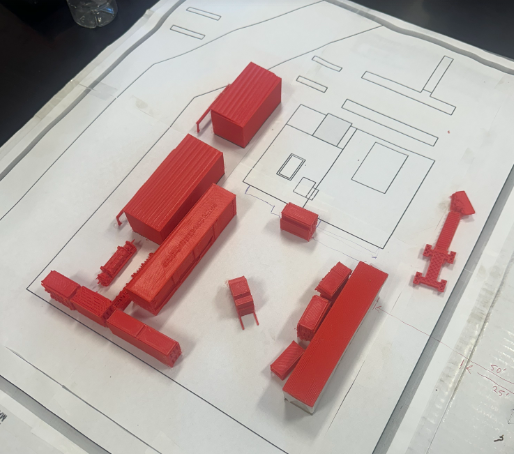

Plant Efficiency Upgrades: Using process flow maps, CAD layouts, and 3D printed models of existing and new equipment/machines to do “paper doll” (paper cut out) exercises to facilitate layout planning instead of relying on 2D drawings to communicate spatial orientation and layout. This will help optimize placement, flows, and maintenance access before anything gets moved.

Equipment Upgrades for Metal Reclamation: They also plan on upgrading existing equipment to capture small percentages of missed metals (e.g., due to shape or size), leveraging improved technology for higher recovery rates of materials like steel, aluminum, and copper, as part of broader process waste reduction.

AI Recognition and Sensor Integration for Material Sorting: They are currently exploring innovative technologies like AI cameras, robotic arms, and sensors (e.g., coils for metal detection) to recognize and sort materials by shape, size, and type, combining data for better decision-making to reduce missed reclamation percentages.

Interested in how other companies are using SOLIDWORKS? Check out more SOLIDWORKS customer stories.