3D printing is an extremely useful technology for spinning up bespoke tooling for the manufacturing line. As always, things get complicated once you start to look at regulatory requirements, and the food and beverage industry, which directly impacts human health, has a high bar of requirements to get through.

Food and beverage industry regulations can be an extremely challenging hurdle for many methods of manufacturing, even when parts or tooling are produced with 3D printing rather than traditional methods of manufacturing.

Parts that come into direct contact with food must meet a wide array of requirements for cleanliness and usability before they are considered safe to use, but even parts that do not directly contact food like secondary or tertiary packaging machinery can also be difficult to source.

Food and beverage parts that are produced via additive manufacturing face their own unique challenges, such as often requiring a dedicated food-grade coating before they are considered usable in the industry. Think robotic grippers for packing and sorting food or even tooling for the packaging line.

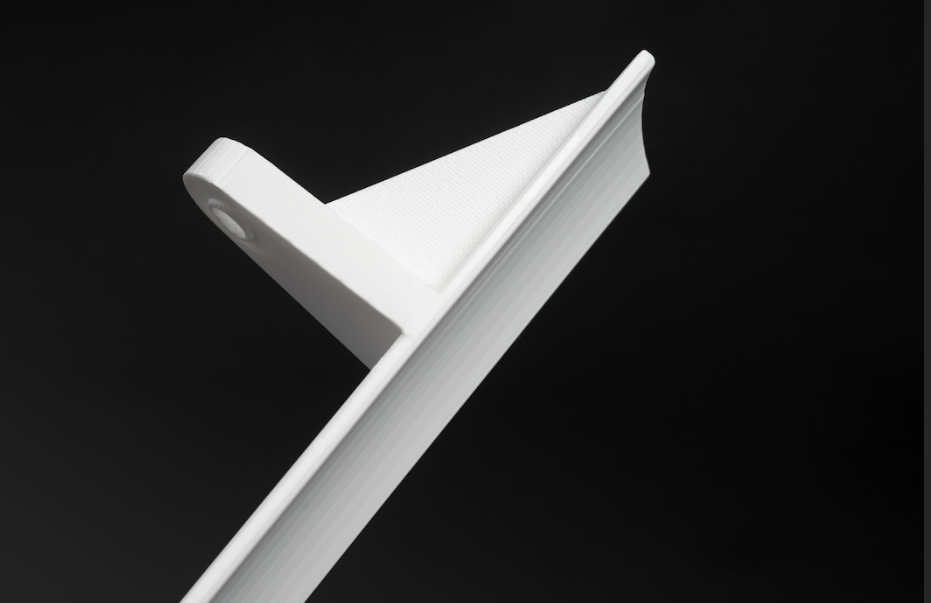

To help users address these challenges, Markforged has developed Nylon White FS – a new food-safe material that is printable on the FX10 Industrial printer.

Food-safe 3D Printing Materials: Just How Safe is “Food-safe”?

As the material name implies, the new Nylon White FS is certified as a food-safe material by the National Sanitation Foundation – NSF for short. For anyone who may be unfamiliar with the classification, food-safe materials are certified to come into direct contact with food. This is an important distinction from a food-grade material, which only certifies the base material, but not always the finished product, for food-contact.

Just because something is listed as a food-safe material, also doesn’t mean it’s the ideal material for your use case. For example, Markforged Nylon White FS is certified for all food contact categories except alcohol.

When evaluating food-safe materials, make sure it covers the specific types of food or beverage you work with. Not sure if a material is truly food safe? You can look for food-safe certifications like Nylon White FS on the NSF website.

Don’t let the label “food safe” fool you — there are many rules manufacturers must follow for tooling and parts to truly be “food safe,” and they are ultimately liable for ensuring these rules are followed. For example, to ensure that the Nylon White FS material maintains its certification, it cannot be reinforced with continuous fibers such as Carbon Fiber or Kevlar.

While this does mean that Nylon White FS cannot reach the upper limits of strength that other Markforged composites can achieve, it does remove all potential food-safety hazards that secondary, uncertified fiber materials might introduce.

Even with using food-safe materials for additive manufacturing, to truly meet food safety requirements requires even more steps. Companies may still need to post-process parts and validate/test part designs against food safety regulations.

Ideal Applications and Uses for Nylon White FS 3D Printing Material

With Nylon White FS being approved for food contact, Markforged has created a material that is a perfect in-house solution for producing manufacturing aids that directly interact with food. Ideal applications for food-safe parts and tooling include:

- Funnels

- Pickers

- Guides

- Grippers

- Custom jigs

- Other tooling for the packaging line

Many of these parts might be difficult to source due to the requirements of food contact certification, so they are a great fit for 3D printing. As a food-safe 3D-printable material, Nylon White FS is also great for any working applications that require certification due to their proximity to food. It’s ideal for guides and grippers and other parts or jigs that undergo moderate to low-stress scenarios. It’s NOT ideal for high-wear scenarios like cutting or grinding.

Learn More about 3D Printing Materials

Hawk Ridge Systems carries a wide library of materials for additive manufacturing, which you can browse in our webstore.

Interested in finding out more about Nylon White FS and if your application is a good fit?

Hawk Ridge Systems has over 25 years in the business of making sure you find the right manufacturing technologies for your business – including which food-safe material is the best fit for your project. Reach out with questions.