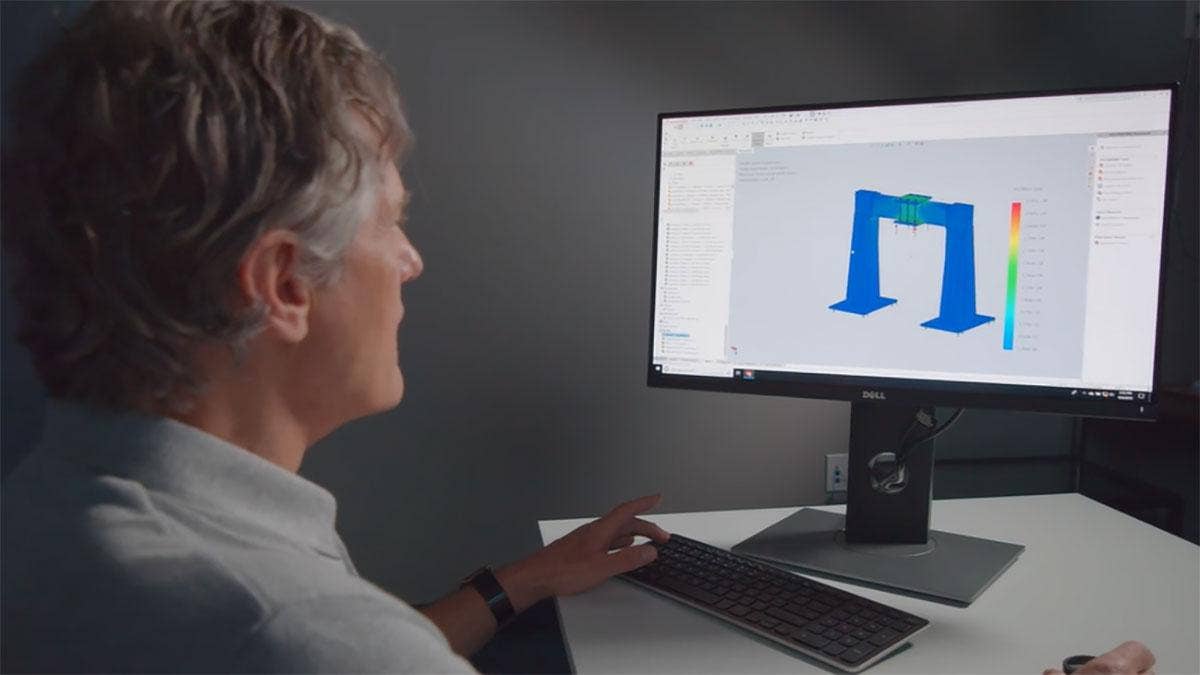

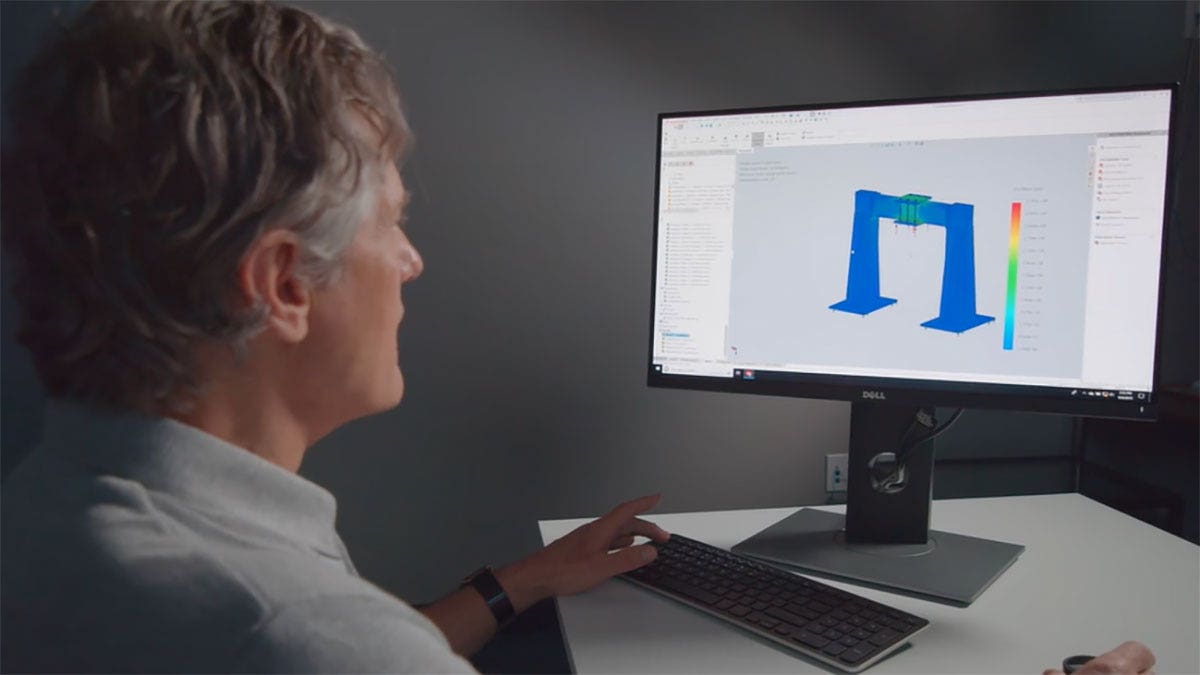

As your design nears completion, you might be concerned with how it’ll perform during a physical test or in a real-life environment. As we know, physical testing can be a costly and time-consuming process and many design issues can be predicted using software like SOLIDWORKS Simulation. With these tools, you can virtually test your design and get valuable insight before leaving the design environment. This allows you to quickly and confidently answer questions like:

- How strong will it be?

- How hot will it get?

- How much will it vibrate?

But what’s the best way to run these studies if you haven’t done this type of work before? Do you outsource or take this on yourself? Before deciding, let’s take a look at the most critical considerations.

Simulation Consulting

The most attractive thing about this route is that you don’t have to do the work! You can just hire an expert to set up the problem for you and provide you with the requested results. That sounds amazing until you realize that consultants have an hourly fee that quickly adds up depending on the complexity of the project.

Did you know that Hawk Ridge Systems offers simulation consulting services? That’s right!

We have many degreed engineers who have countless hours of experience using these analysis tools and you can leverage our expertise. So if you don’t have time, experience or the budget for software we can do it for you. We’ll work together to get the problem setup properly and make sure you understand exactly what the results mean. Often this work can be used as a template or a guide for performing this work yourself. It’s incredibly common to add these capabilities once proven out and incorporate it into the design process.

Bring It In-House

Many customers are happy with the simulation service work, however, we’ve found companies that do this work themselves are able to outperform consultants. Who is more familiar with the design than you? Can you really simulate all the design possibilities you’d want to consider with a consultant?

Utilizing simulation as part of the design process really allows you to innovate. Typically, when outsourcing this work you’ll only run the safest options, omitting the innovative and wild ideas you’ll try if you’re doing the simulations yourself. Many times it’s those revolutionary concepts that are missed due to the expense of running another iteration. When you’ve got the mouse and it only takes a moment, you’ll surely do it.

As mentioned above, this can sometimes be a costly endeavor. Outright owning the software and doing the work yourself will end up saving you money in the long run. Sure, the upfront cost can sometimes be a bit scary, but think of the long-term investment of being able to test the performance of unlimited design options at no additional cost. Think of it as an investment in yourself, learn a new tool and add a skillset to your resume. With our new generation of engineering graduates, their curriculum includes learning some form of FEA or CFD. This means, when they go into the work force ready to design, they have the analysis exposure already which makes the integration of simulation tools seamless.

For more information on selecting simulation tools, check out our Simulation Buyers Guide.

Boost Your Simulation Skills

One common reservation we hear is the time it takes to climb the learning curve to feel comfortable using these tools. One of SOLIDWORKS Simulation strengths is its integration into the SOLIDWORKS CAD environment, meaning there’s no new interface to learn. Our simulation tools have a familiar feel and easy workflow to follow when setting up new analysis studies.

Although our simulation tools are easy to pick up and use, we still advise to take some formal training. We got you covered in that as well! With Hawk Ridge Systems training, you will receive instructional training on your dedicated tool by one of our highly versed engineers. This creates an environment where you are encouraged to ask questions and get the most out of the class. These classes go through multiple examples that will leave you feeling more confident in setting up studies on your own.

While there are pros and cons for each, hopefully by now you have a clearer picture of which option may be better for your needs. It really just comes down to what your short and long term goals are. If you are still not sure, please contact us and our engineers can review your goals and help guide you in the right direction.