Certain objects that you scan may have issues being scanned, including clear and shiny objects, or certain black colors such as carbon fiber. This is due to the capture camera failing to identify faces (in the case of clear objects) or reflects; making the scan noisy for shiny or black objects.

A failed scan of a clear water bottle with no coating.

To correct this common 3D scanner issue, the object needs a coating to add opaqueness to cover the difficult areas to scan. Tape can be used in a pinch, but you may compromise the geometry of the object.

A preferred method is to use a coating developer spray. A quick spray can cover an object with a white powder to add the necessary opaque and color to an object to help with scanning. In this article Airgas’s Radnor is used, but due to the lack of alcohol mix can make it difficult to rub off after scanning. Cantesco or AESUB are both great coating sprays, but are more expensive due to their increased coat quality or removal.

The clear water bottle scanned with Radnor Developer Spray to add opaqueness to the object.

Coating the Part in Spray

After coating the object no other preparation is often needed. If you can’t identify each side of the object for aligning due to the geometry (such as gears, bottles with no logos, or pistons) leaving color marks with markers on the coating can greatly help with alignments.

The bottle rescanned, coming in clearly and without issue.

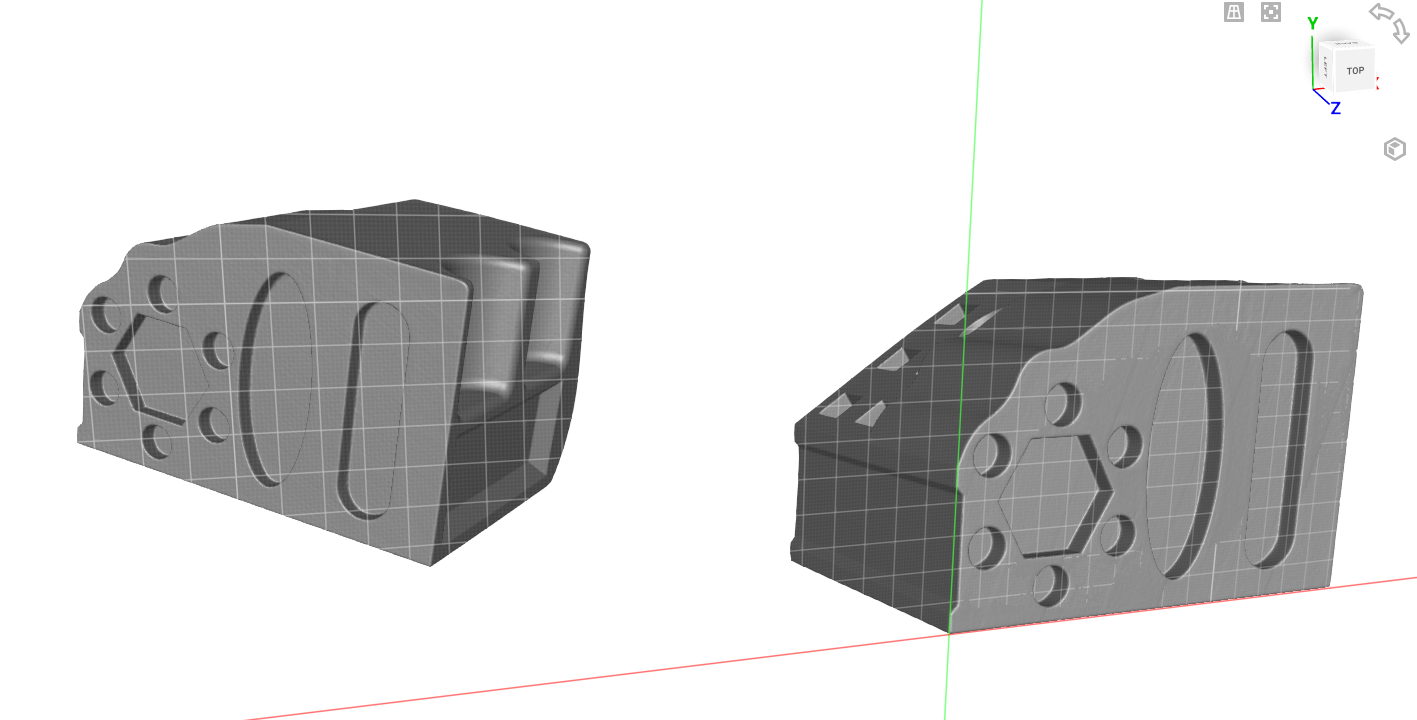

Once the scan finished, global registration and outlier removal is done to clean the scan before running fast fusion.

Fast fusion of the rescanned bottle, even the teeth process without any outlier artifacts.

Since the developer spray applies evenly to a surface and has little to no dust (due to it sticking), the geometry of the object remains smooth – even the teeth can be clearly seen! With a defined outline of the bottle as a mesh, it is easy to reverse engineer or create a case for it.

Curious about the latest technology from Artec, Hexagon and Creaform? Explore our impressive lineup of 3D scanning portfolio products. For any questions, please contact us at Hawk Ridge Systems today. Thanks for reading!