Subdivision Modeling with 3D Sculptor on the 3DEXPERIENCE Platform

Subdivision (Sub-D) modeling is all about making organic modeling easy. If you are a fan of push-and-pull control points (nurbs) we got you covered. SOLIDWORKS has always been an analytical parametric modeling software and that has not changed. What has changed is having the ability to develop organic shapes in-line with your mechanical designs.

Let me introduce the 3DEXPERIENCE role 3D Sculptor and its application xShape. This tool is a next generation Sub-D CAD (computer aided design) technology based on a brand-new modeling kernel which can complement the functions of desktop SOLIDWORKS. It is a browser-based CAD application that completely runs and stores all data in the cloud. Best of all, the organic shapes from 3D Sculptor can be brought back into SOLIDWORKS and integrated with your mechanical designs!

The intent of this blog is to share a short story about one of the biggest challenges I faced back in my furniture design days and how today’s tools would have simplified that process.

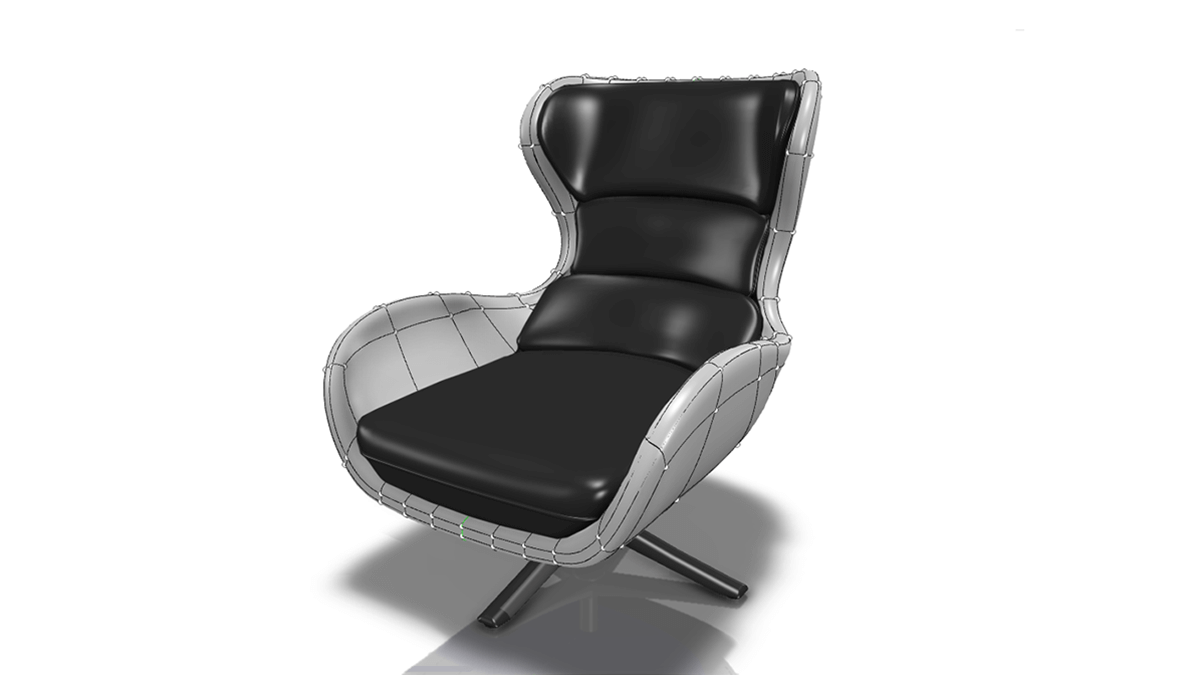

Thinking back, my biggest challenge was the dreaded curved back upholstered chair. I had to design quite a few of these through the years and they always came with unique challenges. With curvature continuous compound angles, this surprisingly complex design always made for a fun time. Here is the 3D Sculptor design breakdown.

What is Subdivision Modeling?

Before we begin, what is Sub-D modeling and why is it better than parametric modeling? (Specifically, when it comes to organic designs?) Sub-D takes an entirely unique design approach where sketches and features are not needed. Instead of using sketch profiles lofted together to create organic shapes, Sub-D starts off with simple 3D geometry, such as a cube, and has intersection points that can be pushed and pulled into any conceivable shape.

Imagine this: You are modeling an ergonomic office chair and you need to create a mixture of disciplines. There are the mechanics of the base and the height adjustment lever. There is also the inner frame that is going to be constructed from welded steel and then you have the fluffy cushions.

I designed fluffy cushions for seven years strictly using SOLIDWORKS surfacing tools. I learned all the tricks and always got the job done. Looking back, however, I spent a lot more time than I want to admit.

If today’s technologies were available when I was designing furniture, things would have been a lot easier. But hey, I would not get this opportunity to share my experience with you! To put it bluntly, the ability to push and pull nurbs makes organic modeling simple.

How is Sub-D Modeling Done Using 3D Sculptor?

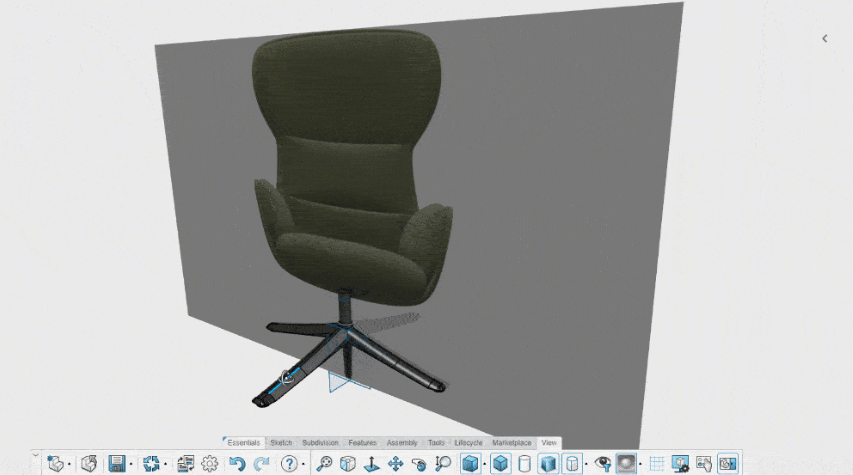

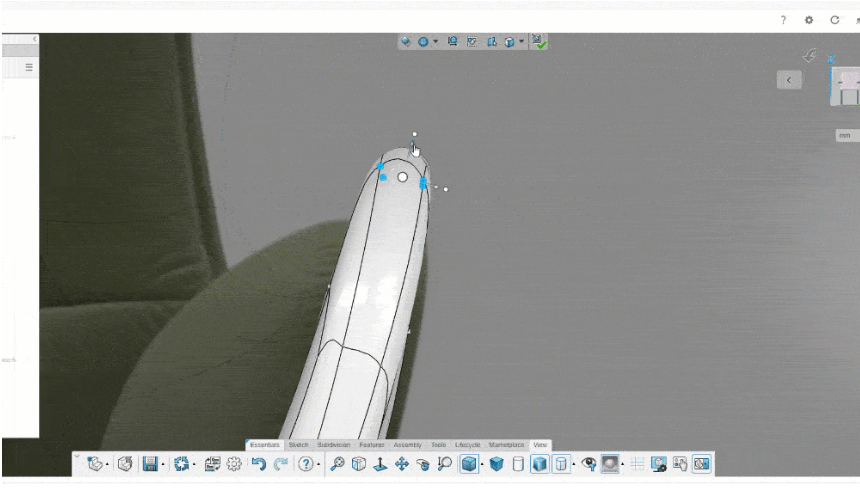

First, I imported a couple 2D images, which gives you the perfect starting point. Think of it as a napkin sketch you are going to trace with 3D digital clay.

From there, it is as easy as dragging a primitive from the subdivision toolbar and shaping it by pushing and pulling the nurbs to match up with the image. Functions like the number of segments and symmetry can be set so you have complete control and predictable design changes.

From there, it is as easy as dragging a primitive from the subdivision toolbar and shaping it by pushing and pulling the nurbs to match up with the image. Functions like the number of segments and symmetry can be set so you have complete control and predictable design changes.

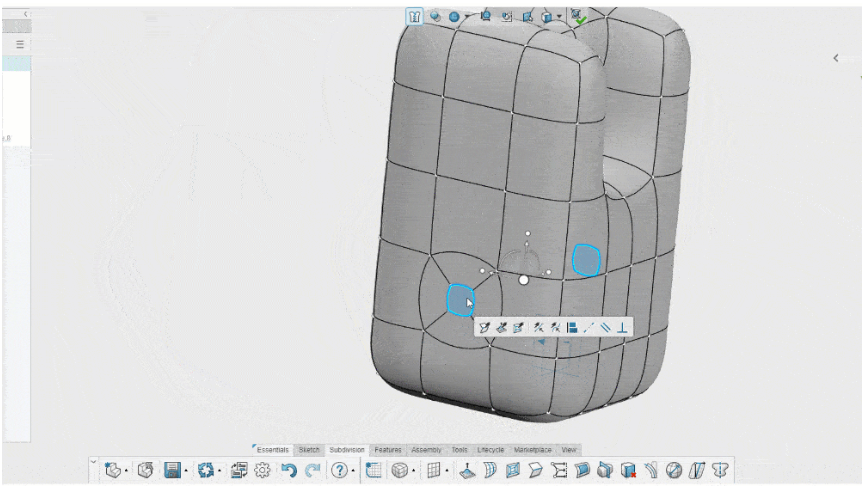

As simple as this all sounds, the process really is that easy. I was able to model the curved back and all the cushions in a fraction of the time it would have taken me in any parametric design software. On top of that, I only used five primitives, pushed and pulled into shape, to do the job.

But wait, there’s more! This was not a brilliant design to show a couple of my favorite features so here is a random example showing the merge-bridging and cut-through model functions.

Are My Designs Stuck In the Cloud?

Lastly, just because we are working 100 percent in the cloud does not mean we have to stay there. I will pass on a little gem before we wrap this up. I exported the design from 3D Sculptor to SOLIDWORKS and rendered a 360 animation in SOLIDWORKS Visualize Professional. I think it turned out nice.

Visit our website to learn more about SOLIDWORKS, and if you have any questions on 3D Sculptor or other CAD tools, contact us at Hawk Ridge Systems and we will be happy to help you! Thanks for reading!