Two popular technologies in additive manufacturing are Stereolithography (SLA) and Selective Laser Sintering (SLS). Both methods have their unique advantages, and many companies employ both SLS and SLA in their additive manufacturing workflows, so it’s not always about choosing one over the other. In this article, we’ll help you understand where each one shines.

SLA or Stereolithography: Using UV Light and Liquid Resin to Create Objects

What exactly is SLA or stereolithography in 3D printing?

Imagine you have a magical machine that can make things out of a special kind of liquid. You pour your special liquid into a tank that can turn it into a solid after it’s exposed to light. The machine shines a special light in a specific pattern and builds your object layer by layer until it’s complete. It’s kind of like making a stack of pancakes, one pancake at a time.

In technical terms, stereolithography (SLA) involves using a liquid resin that is cured with ultraviolet (UV) light to create solid objects layer by layer. This technique offers high-resolution prints with excellent surface finish, making it ideal for producing intricate and visually appealing prototypes. SLA can also achieve exceptional accuracy and detail.

What companies out there are using SLA or Stereolithography as part of their manufacturing process?

Ashley Furniture runs SLA printers forty hours every week. Once they decided to bring SLA printers in-house to speed up their production process, for one nylon part that they used to outsource, they cut lead time from 4 weeks down to 15 hours, and cost per part by 50%.

When Should You Use SLA 3D Printing?

SLA printing is great for creating prototypes, molds and tooling, as well as creating patterns.

- Prototyping: SLA technology is commonly used for early-stage prototyping in various industries, including product design, automotive, consumer goods, and jewelry. Its ability to produce intricate details and smooth surfaces allows designers to assess form, fit, and aesthetics accurately.

- Visual Models: SLA’s superior surface finish and fine detail resolution make it an excellent choice for creating visual models, especially those that require high fidelity, such as architectural models and consumer product displays.

- Dental Applications: SLA has gained popularity in dentistry, where it enables the creation of incredibly precise models and surgical guides. It is widely used for producing dental implants, aligners, crowns, and other orthodontic devices.

SLS Printing: Using Lasers (Pew! Pew!) and Fine Powder to Create Objects

What exactly is selective laser sintering or SLS 3D printing?

SLS printing is a 3D printer that makes things out of materials like super-fine powder. Then a laser draws with light on the powder and melts the powder into a solid, layer by layer, kind of like building a tower with blocks. When it cools, it becomes hard.

In technical terms, selective Laser Sintering (SLS) is another additive manufacturing technique that uses a high-powered laser to selectively fuse powdered materials, typically nylon or other thermoplastics, layer by layer. Unlike SLA, SLS does not require support structures, as the unsintered powder acts as its own support during the printing process.

SLS Printing in Automotive, Aerospace, Consumer Products and Medical Industries

What kinds of companies and industries out there are using SLS printing as part of their manufacturing process?

In the consumer products industry, Rome Snowboards brought SLS printers in-house after working with a service bureau previously. They primarily use SLS printing for rapid prototyping, cutting down their production time from weeks to a single day.

SLS in automotive manufacturing is widely used to create prototypes and even things like internal components and engine parts. For example, General Motors produces over 30,000 prototypes a year and uses many types of 3D printing applications, not just SLS, but also SLM (Selective Laser Melting), FDM (Fused Deposition Modeling), and MJF (Multi Jet Fusion).

Aerospace manufacturers use SLS printing to create lightweight structural parts, brackets, and even engine components for aircraft. Boeing uses SLS printing to make 150 different parts for the F/A-18E Super Hornet aircraft which is used by air forces around the globe.

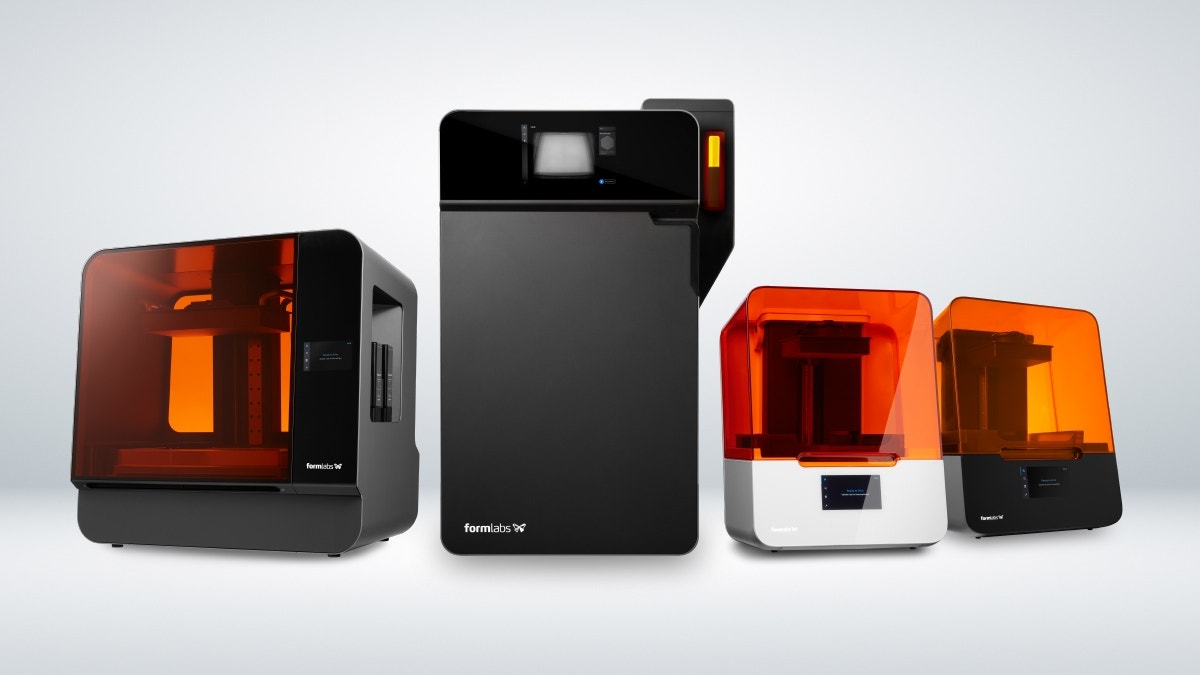

One medical device manufacturer, Partial Hand Solutions, uses SLS printing like the Formlabs Fuse 1 to create patient-specific prostheses such as fingers and elbows.

When Should You Use SLS 3D Printing Instead of SLA 3D Printing?

SLS printing is preferred over SLA when it comes to industrial end-use production and also for functional prototyping. Often larger in size than SLA printers, you can also print much faster with SLS printers because they pack more power.

With SLS, you can also use a wider variety of materials such as ceramics, nylon, polystyrene, and metals, while with SLA you are limited to polymers and resins.

- Functional Prototypes: SLS technology excels in producing functional prototypes that require mechanical strength and durability. Its ability to work with various materials, including high-performance polymers and composites, makes it suitable for engineering applications such as aerospace, automotive, and industrial machinery.

- Small Batch Production: SLS is often employed for small batch production runs due to its ability to create complex geometries without the need for expensive tooling. It enables manufacturers to quickly iterate and produce functional parts or end-use components.

- Customized Prosthetics: SLS can be leveraged in the healthcare field to fabricate customized prosthetics and orthotics. Its ability to produce complex shapes and designs makes it a valuable tool for creating patient-specific medical devices.

Choosing Between SLS and SLA printing: Strong, Durable Objects or Super Smooth High-Precision Objects in a Hurry?

To put it in simple terms:

Choose SLS printing when you need: Strong, super durable objects and greater flexibility in material choices.

Choose SLA printing when you need: Super detailed, smooth and intricate objects made with precision or when you’re in a hurry because SLA is much faster than SLS printing.

Ultimately, the choice between SLA and SLS depends on the specific requirements of your project. Here are a few factors to consider:

- Design Complexity: If your project demands intricate details and smooth surface finishes, SLA may be the better choice. However, if your design requires mechanical strength and more functional properties, SLS might be the right technology.

- Material Selection: While both SLA and SLS offer a wide range of materials, SLS has an advantage in terms of material selection. It can work with thermoplastics, composites, and even metal powders, providing more options for specific project needs.

- Production Volume: If you require a few high-quality prototypes or individual customized parts, SLA can meet your needs with its high accuracy and surface finish. For larger production volumes or small batch manufacturing, SLS can offer cost-effective solutions.

Putting it altogether: SLS versus SLA 3D Printing

Stereolithography (SLA) and Selective Laser Sintering (SLS) are two transformative 3D printing technologies that bring immense value to diverse industries. Each technique has its strengths and ideal use cases. SLA shines in early-stage prototyping, visual models, and dental applications, while SLS excels in functional prototypes, small-batch production, and customized prosthetics. Carefully evaluating your project’s requirements will guide you to choose the most suitable technology and achieve optimal results in terms of accuracy, strength, surface finish, and cost-effectiveness.

Want to learn more? Check out our webinar on SLS versus SLA printing in additive manufacturing: