In 2019, Markforged introduced four new metals for their Metal X 3D printer, including Inconel 625 and D2 Tool Steel. Read about all previously released Metal X materials in our related blog post.

Now, Markforged is opening its Metal X platform to even more applications by introducing the ability to 3D print pure, non-alloy Copper.

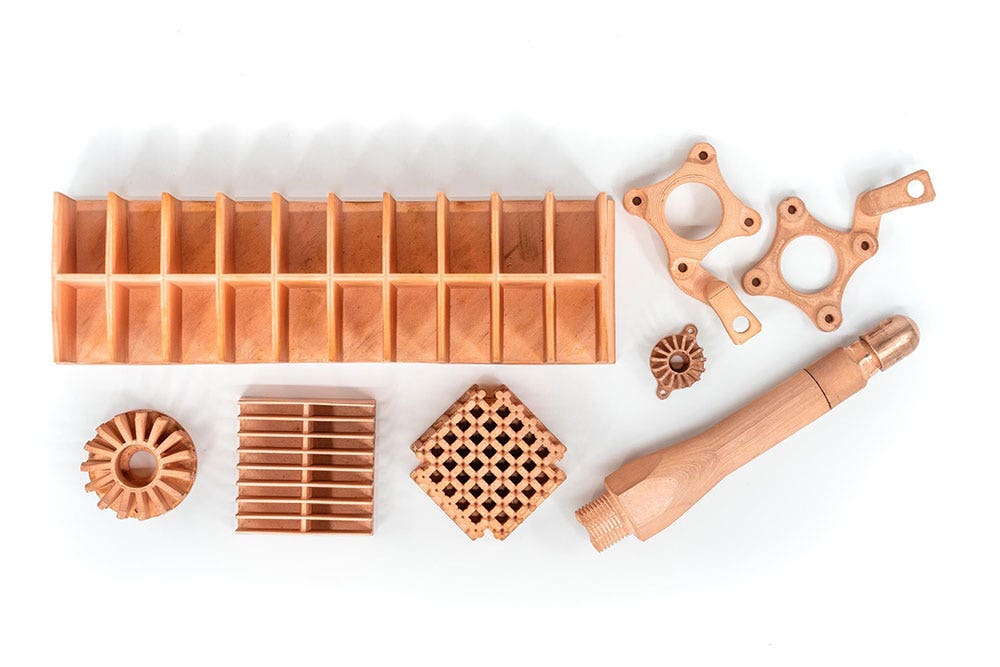

Examples of parts that were created with the Markforged Metal X 3D printing process.

Overcoming Challenges

In the world of manufacturing, the low hardness values of Copper can make it difficult to machine. Copper also has high reflectivity, which is problematic for many Direct Metal Laser Sintering (DMLS) 3D printers that use lasers to fuse metal powder.

By using the same 3D printing process as all other Markforged metals, Copper can be printed without needing to take precautions against airborne metal powder. In turn, this lets users create parts and geometries that could be difficult to machine. It also reduces lead times that can be associated with outsourcing.

A short clip that demonstrates how Markforged Copper parts are printed, washed and sintered.

Applications

Copper is widely utilized in areas that require high thermal and electrical conductivity. Because the Markforged Metal X is able to print pure Copper, almost any traditional application is able to be printed and used in either a prototype or end-use fashion. This includes applications such as heat sinks or spot welding.

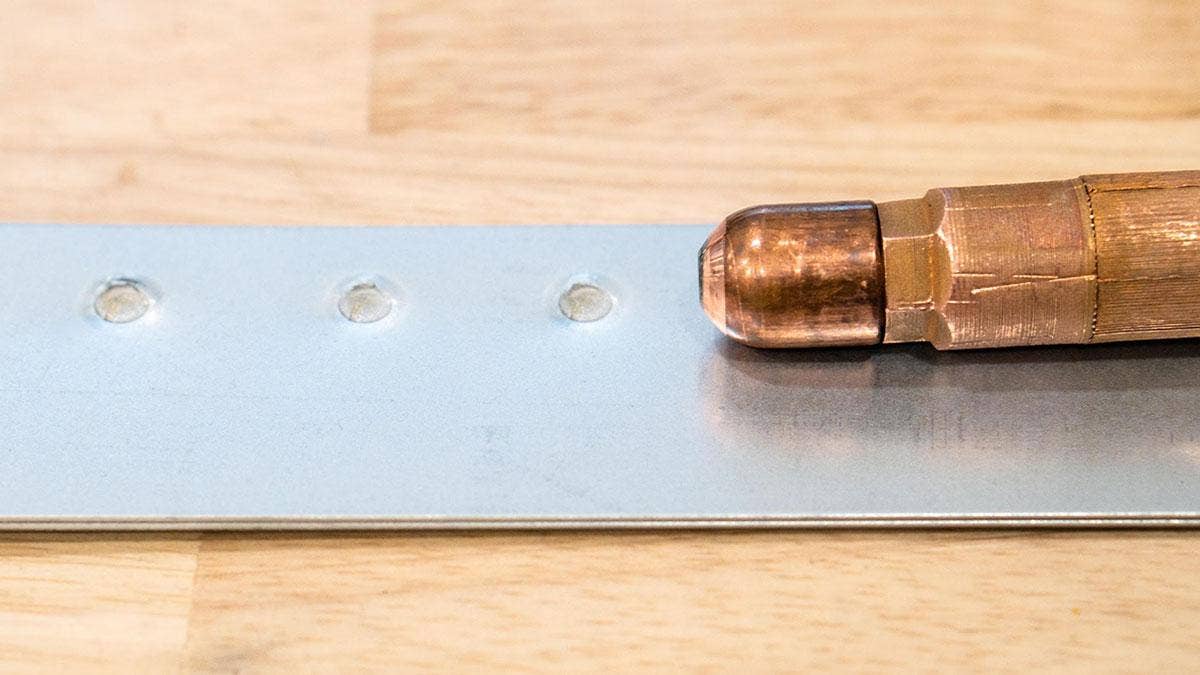

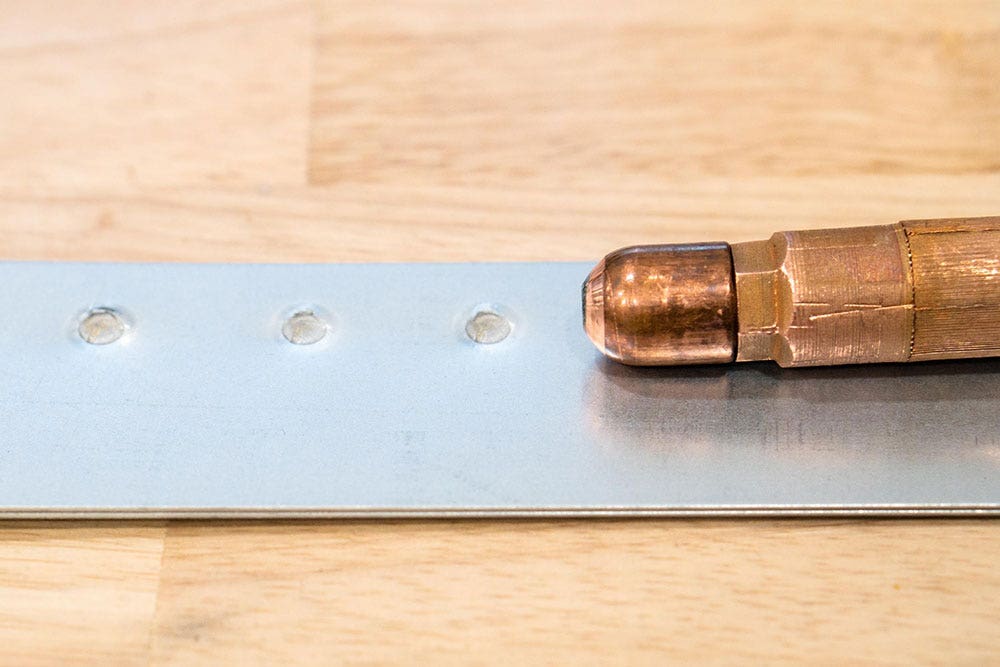

An example of a Copper spot welder printed on the Markforged Metal X.

By taking advantage of the strengths offered by 3D printing, complex geometries such as internal cooling channels can be considered.

Lastly, the Metal X can print solid parts that are 98 percent dense. This leads to consistent performance that is comparable to machined Copper parts. If weight is a concern, the Metal X can still produce Copper parts with an infill. This would would be impossible via traditional machining.

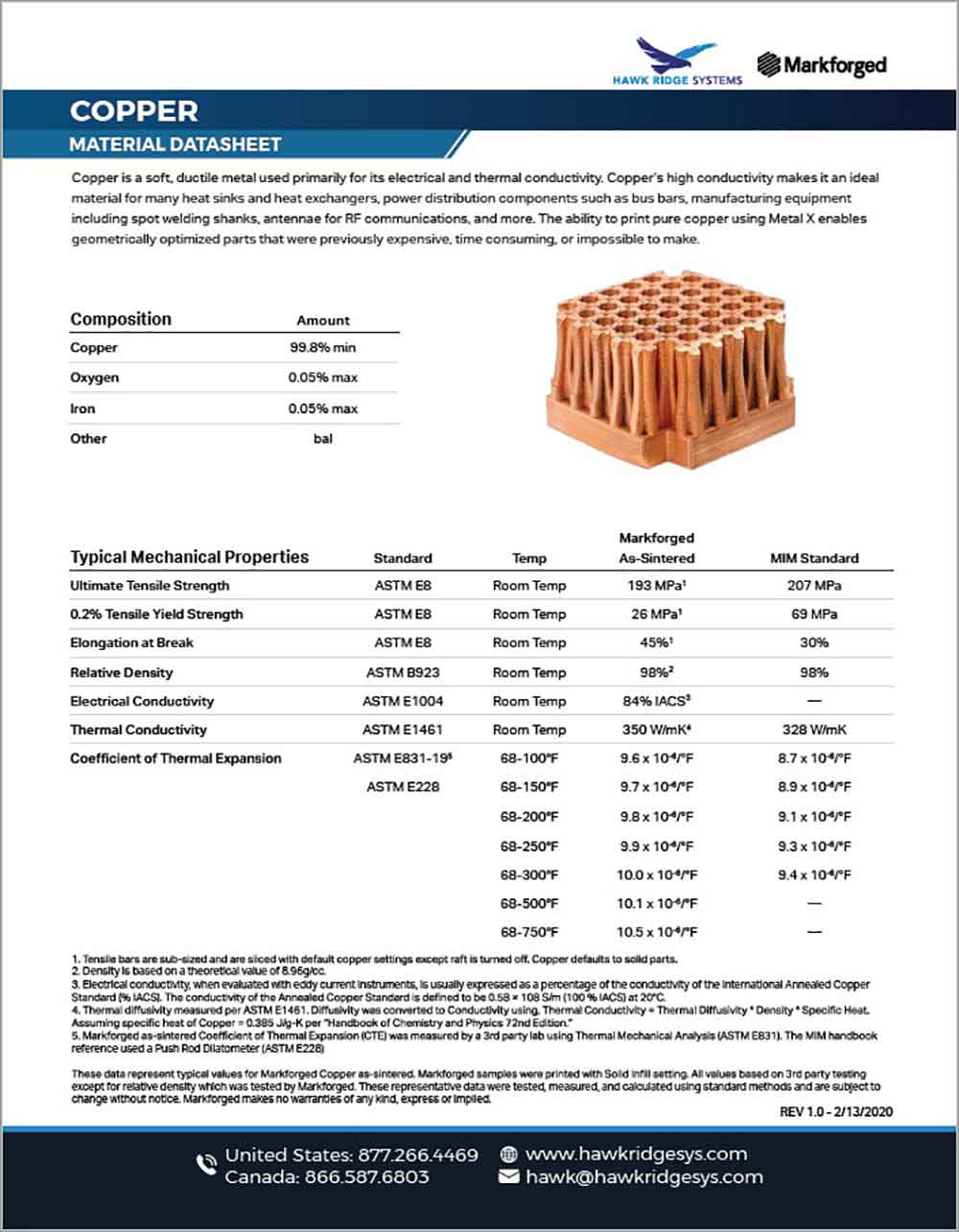

Click on the above data sheet to download the Metal X Copper datasheet.

Visit our website for more information on Markforged or if you have any questions, feel free to contact us at Hawk Ridge Systems today. Thanks for reading!