Supply chains are a necessary evil. You can’t get a product to the consumer if you don’t have the right materials, suppliers, producers, distributors, and assembly mechanisms.

But each of those facets requires two things: time and money.

Wouldn’t it be nice to reduce the amount of downtime and expense it takes to bring a product through the supply chain? Enter additive manufacturing.

Additive manufacturing, or 3D printing, doesn’t necessarily replace traditional manufacturing. Instead, it solves challenges that can reduce expenses, slow down, or even some supply chain disruptions.

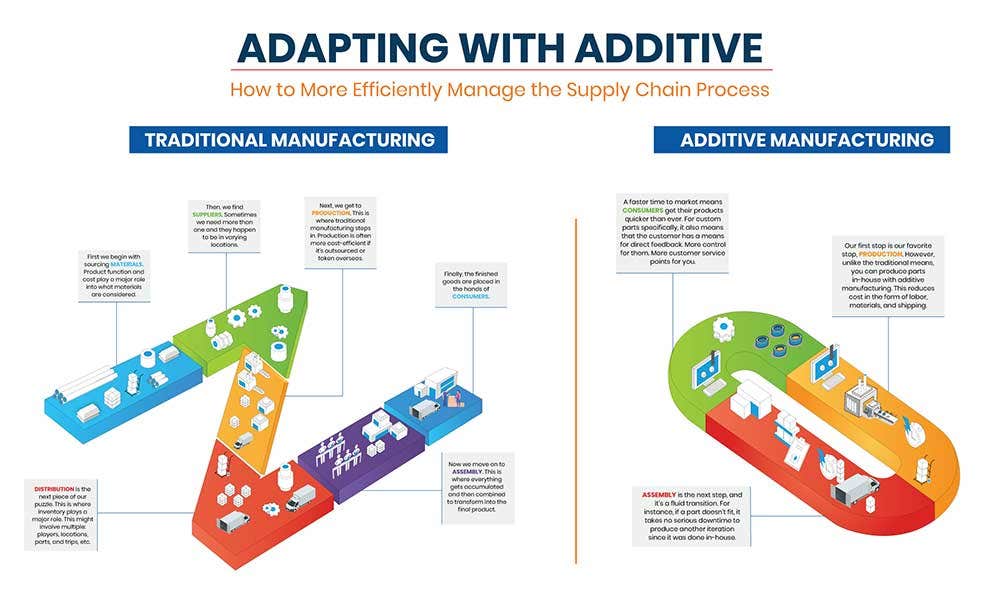

We put together an infographic that walks through both traditional and additive manufacturing and how additive manufacturing can change some of those bottlenecks.

Let’s look at how 3D printing solves problems at every step of the supply chain.

Materials and Suppliers: 3D Printing Material at Your Fingertips

Let’s dive into materials and suppliers since these can affect product function and cost. Once a product is designed, you might ask yourself questions like these:

- What materials will I use to create the product?

- Which suppliers can provide the best materials quickly and/or at a low cost?

In a traditional manufacturing process, a manufacturer will likely seek out bids from multiple suppliers. Sometimes, you may need more than one supplier to bring your product to life, and you could have several suppliers in many locations. This can be time-consuming to build into your production cycle for every single component within your design.

But what if you can bypass some parts of the supply chain to get the parts you need?

There are a ton of materials you can choose from when it comes to 3D printing. Instead of seeking out bids, you’ll have a more streamlined process where you’re researching and shopping for what’s right for you.

How to Leverage Additive in Your Process

For example, with 3D-printed materials as strong as Markforged’s Onyx (a micro carbon fiber filled nylon) and metal at your disposal, 3D printing even just a few of those parts will reduce lead time and costs, helping you get your product to market faster.

Production: 3D Printing Keeps the Lights On

Now, heading into production, some manufacturers find this step to be costly in traditional manufacturing compared to additive. Some will outsource their manufacturing needs to manufacturing-as-a-service (MaaS) providers to help keep costs within their budget.

With traditional manufacturing, the supply chain often feels more like a supply wall that you must slowly climb over as you wait for your parts to be made.

3D printers optimize your production in multiple ways and allow you to embrace more sustainable strategies.

How to Leverage Additive in Your Process

For example, if a tooling component in your machine breaks, don’t stop production to wait for a new one to arrive. 3D–print the part and get back up and running within hours, not weeks.

3D–printed materials are also typically lighter than traditionally made ones. Parts that are lighter move faster, decreasing your production time and increasing your output. Imagine the cost benefits of improving your efficiency by even a few percentage points! Additive manufacturing can make that happen.

Assembly: 3D-Print What You Need Now

With production squared away, we move on to the next step: assembly where everything gets accumulated and then combined to transform into the final product. Automated assembly loves a little help from additive.

Traditional manufacturing processes can involve several steps, such as preparing the parts, pre-assembly before having a main assembly, quality control and testing, and finally, packaging. Because there is a lot packed into the traditional process, it can take some downtime to resolve issues and thorough planning to get it right.

In additive manufacturing, assembly is a fluid transition compared to traditional processes.

How to Leverage Additive in Your Process

For instance, you have a part that doesn’t fit. It won’t require massive downtime to produce another iteration and keep your production moving forward.

Manual assembly also levels-up its quality control, speed, and safety with a 3D printer on hand. Custom design and 3D print assembly jigs and stationary fixtures to make sure the part is put together correctly, quickly, and safely every time.

Consistency in manual part production also allows you to reduce the ratio of parts that must be checked for quality control. The savings just keep coming when a 3D printer is on your shop floor.

Distribution: Make It “Extra” for Unexpected Times

A lot can happen to materials, components, and products as they make their way from the suppliers to your front door. The delivery truck could break down. A tsunami could hit. A global pandemic could bring the economy to its knees (that last one could never happen, right?).

Distribution challenges disappear when your parts and materials are already on hand or nearshore.

How to Leverage Additive in Your Process

For example, you can 3D-print extra parts and end products you need and purchase extra material to have in storage.

Delight Them: Giving Your Customers a First Look

The best way to sell a product is to let your customers feel, touch, and use it. Don’t just show them a 2D picture of your product. Send your sales reps out with 3D-printed samples, and your customers will know exactly what they are buying.

If customization is key, 3D-print a prototype to make sure the customer gets what they want before you spend weeks (and dollars) making the final product on your traditional equipment.

Strong 3D printing materials like copper, Kevlar, and steel are end-use capable, which means customers can test-drive parts within their own machinery. It won’t cost much to make endless changes with a 3D printer.

But the perceived added value of providing your customers with quick and easy options will be well worth the investment.

The Final Note

Take control of your supply chain and business. Manage them effectively and efficiently by bringing additive manufacturing onto your shop floor. Your traditional equipment will thank you, and so will your bottom line.

Ready to manage your supply chain with Formlabs 3D printers or Markforged additive solutions? Contact us today!