Technology has a way of making things better — it speeds up processes, streamlines workflows, and turns the impossible into the possible. The manufacturing industry has seen the impact of innovation play out time and time again. This time, it’s all eyes on 3D printing.

What Is 3D Printing?

3D printing — a type of additive manufacturing — builds objects by layering material following a digital design. Where some aspects of traditional manufacturing remove material and create waste like with prototyping, 3D printing only uses what’s actually needed. The result is faster, more efficient, and cheaper production.

These benefits are just the tip of the iceberg too.

3D printing is important in manufacturing because:

- It’s extremely flexible. You can manufacture parts too complex for certain manufacturing technologies.

- It’s customizable. You can build products that align perfectly with your or your client’s very specific or niche needs.

- It enables on-demand production. You can produce parts when you need them instead of paying for storage and inventory management.

What Does This Mean for the Manufacturing Industry?

Simply put, growth in the demand for 3D printing.

The 3D printing market was forecasted to skyrocket. But no one expected it to expand at breakneck speed. By the end of 2024, estimates suggest the global industry will be valued at $28.07 billion — that’s a number 10.5% bigger than predicted. By 2028, this figure will hit $57.1 billion.

Even early adopters are ramping up their use of 3D printing. Seven in 10 businesses that used 3D printing in 2022 printed even more parts in 2023.

3 Key Trends Driving the Demand for 3D Printing in Manufacturing

Why is everyone rushing to 3D printing? In short, because it’s a solution to so many of the challenges today’s manufacturers face.

1. The Demand for Customization and On-Demand Production Is Up

In general, consumers expect more personalization than ever before. This trend is playing out in manufacturing too. Here’s how:

- More clients want customized parts. Perhaps you’ve noticed this firsthand. You want to meet these shifting needs, but traditional methods make custom manufacturing slow and expensive. In contrast, 3D printing can create customized products — even in small quantities — cheap and fast.

- Your industry might change fast, and when it does, you need to adapt. The problem? You have a stockpile of parts that have all of a sudden lost their worth. You can mitigate this risk by printing on demand. Your business becomes more resilient and agile. Some companies seek manufacturing-as-a-service (MaaS) businesses to help with 3D printing needs if they don’t have an in-house team or equipment for short production runs or one-off projects.

2. Materials and Technologies Are More Advanced

3D manufacturing has come a long way. The leaps and bounds in progress we’ve seen in the past few years now make it possible to print high-quality, long-lasting parts that can be alternatives to some traditional manufacturing methods — thanks to:

- New 3D printers are capable of printing more than just plastic. Now, printers can manufacture products from metal, ceramic, and bio-materials.

- New printers are faster too. They are more precise, capable of achieving incredible complexity, and can use several materials at once.

3. Manufacturers Want Cost Efficiency and Time Savings

Manufacturers rely on raw materials. These are subject to the ups and downs of the global market. In addition, some supplies are limited, which is only exasperated by labor shortages and rising transportation costs.

3D printing can help alleviate these financial pressures by:

- Eliminating the need for molds and tooling and instead going directly from design to production.

- Cutting production time down from weeks for a prototype to days or hours.

- Using only the amount of material required to reduce waste and cut costs.

For companies without in-house 3D printing systems, MaaS businesses can be an ideal way to bring their products to market faster, so companies don’t have to make large upfront investments in specialized equipment before starting their projects. A good example of a MaaS is our trusted business partner, A3D Manufacturing.

Top Applications of 3D Printing

3D printers help companies across industries. Here are some applications:

- Healthcare: Think about custom medical devices and machinery parts for better patient care. Read our industry whitepaper to learn about how 3D printing changes the game for the medical industry.

- Aerospace and Defense: Think lightweight, extremely durable parts that adhere to complex and highly regulated industry regulations. Read more about aerospace and 3D printing in this industry whitepaper.

- Automotive: Think of custom tools, durable end-use parts, and more. One of our customers, Larsen Motorsports, a leader in jet engine drag racing, needed a custom steering wheel for jet car driver Josette Roach. The part needed to fit Josette’s hands like a glove — her safety and comfort depended on it. They achieved it using a Markforged 3D printer and advanced simulation software.

- Industrial Equipment: Think on-demand sturdy spare parts, functional intricate end-use parts, and more. Read more about how to increase uptime and efficiency as industrial equipment manufacturers.

Regardless of where you operate, the benefits of 3D printing in the manufacturing industry are clear:

- You can create rapid prototypes, speeding up development and enabling more iterations. The outcome is a superior product with a faster time to market.

- You can produce parts in small batches without investing in expensive tooling.

- You optimize your supply chain. You don’t need large inventories. If a part is needed, it can be printed and delivered — no delays.

Steps and Tips to Get Started Today with 3D Printing

Keen to get started with 3D printing? Here’s how implementation might unfold:

- Step 1: Think about where 3D printing can add the most value to your operation. Write down your specific needs, like the type of material, for example. Use these insights to guide your decision-making.

- Step 2: Select a printer that meets your needs. If you’re not quite sure, reach out to the Hawk Ridge Systems team — we can give you personalized advice.

- Step 3: Integrate your printer with your design software.

- Step 4: Run a test print to make sure everything’s working as expected. Flag issues and address them before you begin manufacturing.

- Step 5: Train your team, so teammates know how to use your CAD software and the printers. Then, it’s time to go live!

Here are three top tips for maximizing your 3D printing efficiency:

- Use 3D printing to create prototypes before moving to mass production. Catch design issues early and make adjustments without wasting materials.

- Choose the right material for the job. This will improve the longevity and performance of your parts.

- Inspect your 3D printing technology and perform preventative maintenance. That way, you avoid downtime.

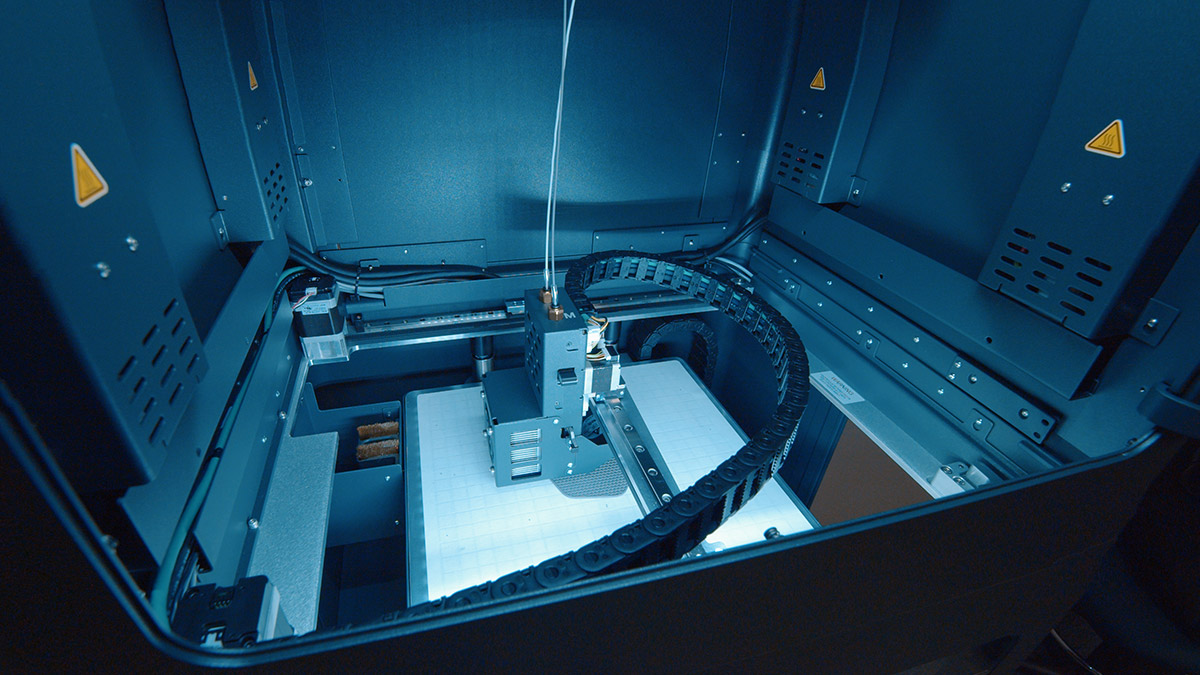

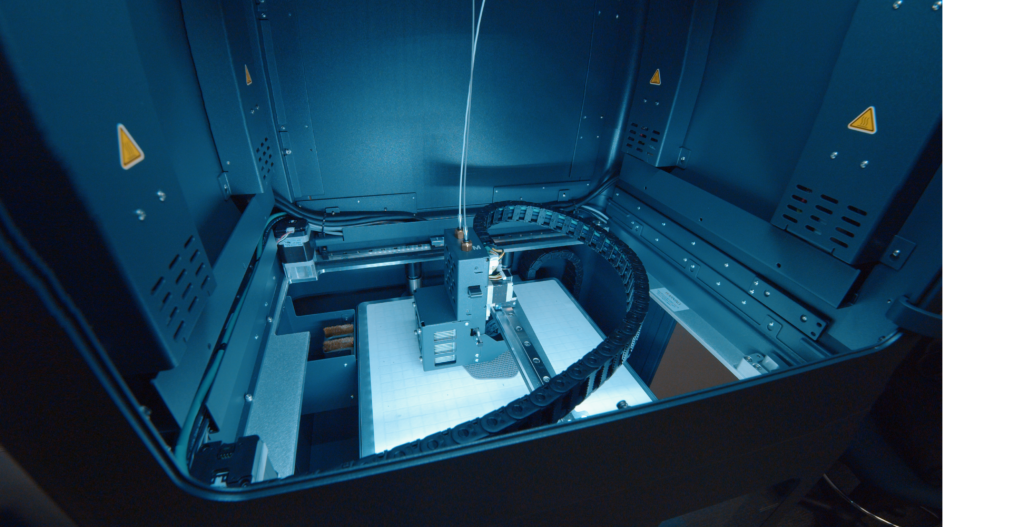

How We Meet Industry Needs with Industrial 3D Printers

Here at Hawk Ridge Systems, we keep our finger firmly on the industry’s pulse. We understand the needs of the modern manufacturer, and we know our leading-edge 3D printing solutions can solve problems and fuel our clients’ growth.

Our industrial 3D printers include:

- Markforged FX10: Ideal for factory floors needing large, sturdy parts for tough conditions. Think printing industrial end-use spare parts, jigs and fixtures, and tools.

- Markforged FX20: Ideal for large, robust high-temperature parts for the harshest environments. Think printing parts for defense, aerospace, and automative industries.

- Markforged Metal X: A complete, easy-to-use solution for strong metal parts. Think about an end-to-end metal 3D printing solution that reduces the cost of traditional manufacturing methods.

- HP Multi Jet Fusion 5000 Series: A high-speed printer that produces detailed, accurate parts. Think injection molding for short-run production.

These high-tech printers address key industry demands with speed, strength, customization abilities, and cost-efficiency.

Our Take on Future Trends in 3D Printing for Manufacturing

So, what’s next in 3D printing? Here’s what we predict and how our Hawk Ridge Systems’ team is preparing:

Greater Use of Metal

Industries like aerospace, automotive, and defense need strong, lightweight materials that can withstand extreme conditions. Metal printing will become the go-to solution for high-performance applications.

We already offer the Markforged Metal X. This printer produces strong, end-use metal parts.

More Value on Sustainability

Consumers value sustainability. More than 70% of them will pay more for a green product. Manufacturers are starting to acknowledge this and invest in lower-waste, more energy-efficient solutions. 3D printing is uniquely positioned to help.

Our printer range includes the HP Multi Jet Fusion. This ultra-precise printer produces parts with minimal waste.

3D Printing Beyond the Prototype

3D printing has long been touted as a technology for prototyping. But today’s — and, no doubt, the next generation — printing technology is capable of producing parts robust enough for end-use. In addition, industries like automotive, construction, and industrial equipment will look to leverage 3D printing for larger-scale products.

The Markforged FX20 can produce large parts. For organizations that need tough or oversized components without sacrificing precision, this is the printer for you.

The Final Note

The landscape of manufacturing is now being shaped by 3D printing. It’s faster, more flexible, more sustainable, and more customizable.

Ready to enhance your manufacturing processes with advanced 3D printing solutions? Contact us to learn more about our top industrial 3D printers.