So you’ve done it…you’ve sunk your life’s savings (or should that be wife’s savings) into a CNC. You’ve taken the garage door off, cut a hole in the roof, broke your back in 5 places and dropped a thousand bucks into a curse jar but you’ve got your machine in its final resting place. You’ve jogged it around, loaded up the hand-written g-code that you spent all of Sunday night writing, double checking, and testing… without crashing…much. And you’ve quickly realized that conversational programming is about as fun as explaining to your wife why she must park on the street and why your kid needs to get a job because their college fund is ‘invested’ in a big box in the garage. And let’s not forget, it means tying up the machine and being stood in the cold shop.

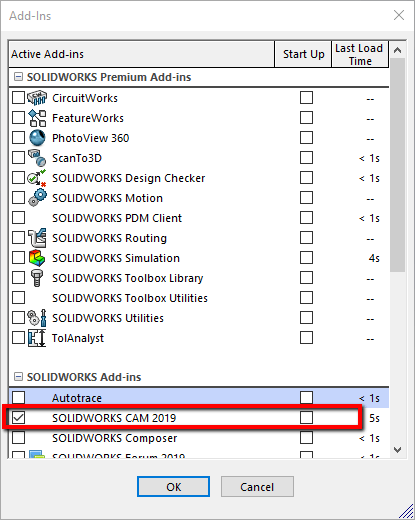

You want to get some of that alpha-numeric gibberish created without so much as straining a pinkie. Well lucky for you, the kind folks at SOLIDWORKS give you a CAM system with every seat of SOLIDWORKS on subscription. So fire up your SOLIDWORKS and check on the SOLIDWORKS CAM add-in from the Tools>Add-Ins menu.

What is the Difference Between SOLIDWORKS CAM Standard and Professional?

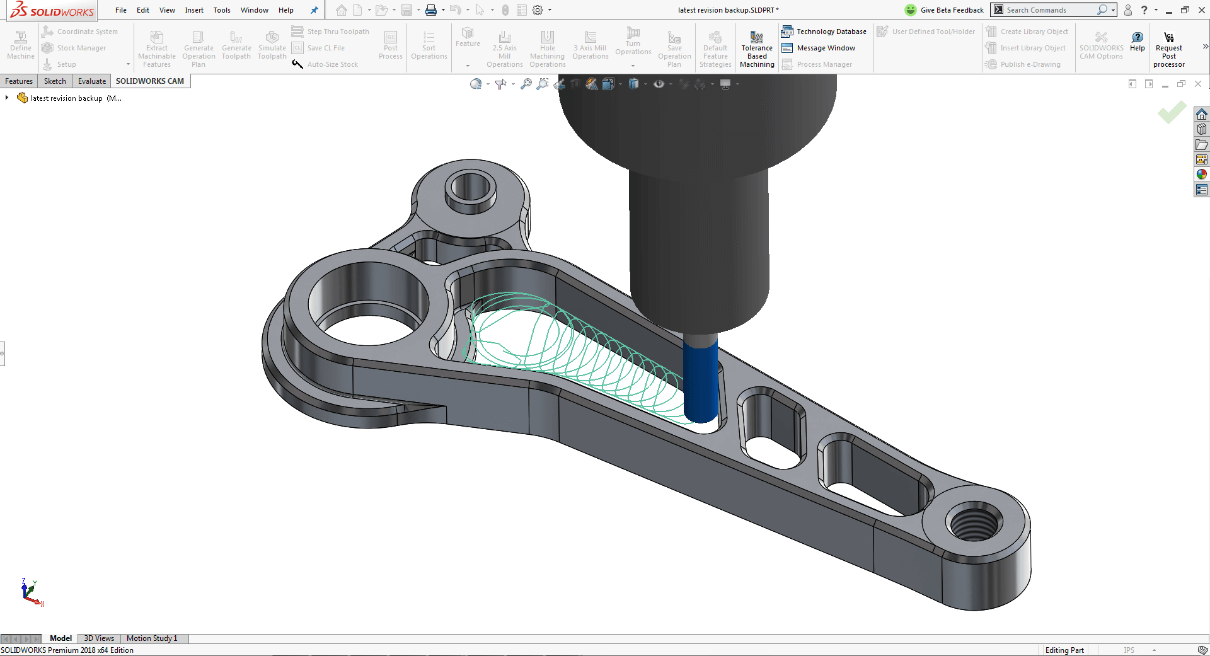

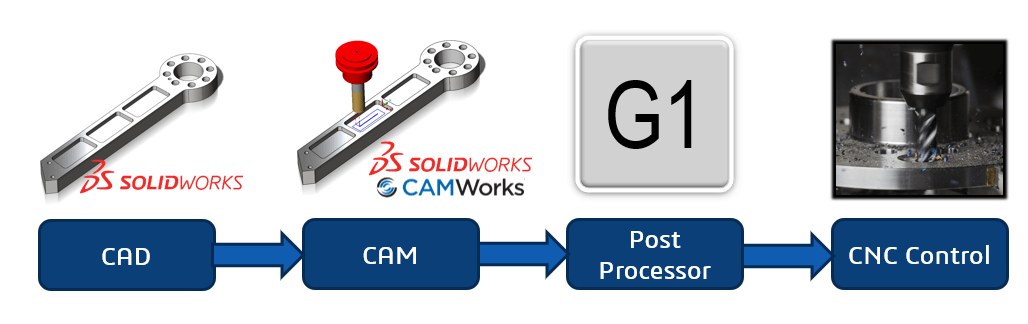

So what are we looking at here? Well, SOLIDWORKS CAM Standard is a 2.5 Axis CAM package that’ll generate toolpath on SOLIDWORKS part files and produce CNC code (G-code) for a CNC mill, waterjet, plasma or router. “What’s this 2.5 axis you talk of?” I hear you ask. It simply refers to the way the machine motion cuts the material. Whilst most CNCs are at least 3 axis, ie they are able to be controlled in an X direction, Y direction, and a Z direction, the method used to cut parts typically involves only moving 2 of these axes at one time, usually XY. The third axis remains at a fixed depth, only changing the depth once the X and Y axes have stopped moving. Struggling to picture it? Think of how a 3D printer builds material up but instead of moving upwards at the end of a layer, the tool is moving downwards to cut deeper into the material.

What about a turning for a lathe, you ask? Not a problem, you’ll just need to upgrade to SOLIDWORKS CAM Professional. If you do, you’ll also get the ability to program assemblies if you want to crank out multiple parts in one program (think of a nest for a router/laser or multiple setups in one shot). You’ll also benefit from the ability to run 4th and 5th axis indexing machines as well as some neat high feed roughing capabilities using Volumill.

Let’s Get Started with SOLIDWORKS CAM

Take a celebratory sip of your favorite brew, stretch those knuckles, as we’re about to walk you through getting started with SOLIDWORKS CAM.

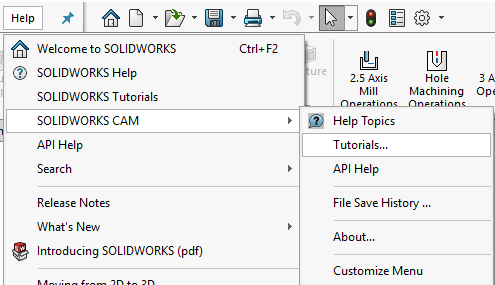

You’ve managed to get it loaded up, but not sure where to begin? Don’t fret, we’ve got your back. If you want to take a look in your own time, I’d recommend kicking things off by checking out the tutorials. You can either go to Help>SOLIDWORKS CAM>Tutorials or browse to them in the following directory:

C:Program FilesSOLIDWORKS CorpSOLIDWORKS CAMlangEnglishManuals

The files to accompany these tutorials are located at the following location:

C:UsersPublicDocumentsSOLIDWORKSSOLIDWORKS 2019CAM Examples

You can also check out our Hawk Ridge Systems YouTube channel for a whole bunch of videos walking you through various aspects.

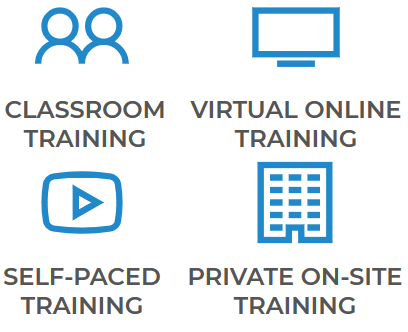

What SOLIDWORKS CAM Training Options are Available?

Need to get proficient ASAP? Check out our range of CAM training offerings, whether you’re a beginner or a seasoned CAM pro! Prefer the comfort of your own home, we have online offerings so you can sit around in your PJs if you so wish. If you prefer speaking face to face, you can come to us or we can come to you. Not got a big budget but don’t want to have to watch endless videos that just end up confusing you? Check out our self-paced training videos for a guided curriculum, walking you through the steps. View Hawk Ridge Systems Training Options

Where to Access Free Post Processors?

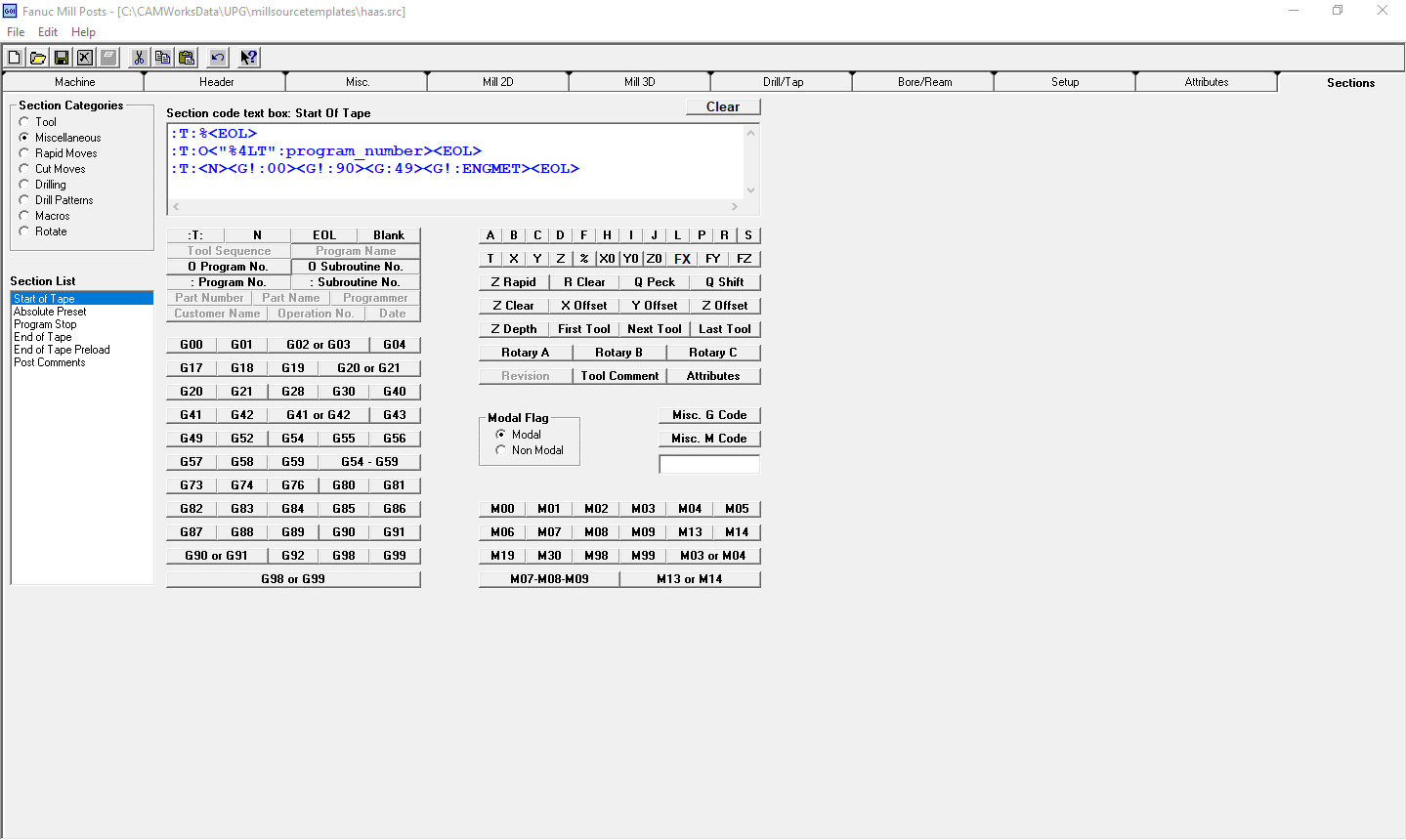

Let’s keep going on the right track and not spend all day searching high and low for the tools to do the job. You’re going to need a Post Processor. Without it, your CAM system is about as much use a glass hammer or rubber nails…heard those before? Good, you’ll fit right in. It’s quite possibly the most overlooked portion of any CAM system, but it’s one of the most crucial. After all, you wouldn’t go dropping thousands on a race motor and then bolt on some cheap and nasty retreads on, would you? Do yourself a favor, flex those knuckles and make your way over to our website. Not all posts are made equal.

Download a free post processor for SOLIDWORKS CAM/CAMWorks

Don’t see your machine listed? Well lucky for you there’s a couple of other options. Think you’re a bit of a software whizz-kid and know your way around an IF statement or two? Check out the following to download the Universal Post Generator so you can create and edit your own post.

Download Universal Post Generator

Prefer to focus on programming the machine rather than learning what a variable and a section are? Let us handle it for you. For a fixed price, we’ll build a post for you, tailor it to you and your machine’s preferences and provide support just in case you do run into any issues. Just drop your information into the Get a Custom Post form and we’ll reach out to you.

Ready to let rip and make some chips?! Don’t let me hold you back. If you want to dial things in and get your database tuned up, you may want to check out the following links to customize your Machines and get your Tool Crib set up.

Have questions? Please contact us and we will point you in the right direction. Or you can get started with a free trial of SOLIDWORKS CAM. Thanks for reading!