At its core, the field of additive manufacturing is built around sustainability and lowering carbon footprint. 3D printed parts are typically created using only the media that is necessary to form geometry, and some 3D printers are even designed to print using mostly recycled material. With supply chain issues becoming increasingly prevalent, being efficient and sustainable is one of the top goals for many organizations. To assist with this, AMT has announced their FDA-approved and completely plant-based vapor smoothing solution, PostPro Pure.

Same Results, Sustainable Chemistry

AMT systems such as the SF100 can vapor smooth 3D printed parts by sealing them in a chamber that regulates both temperature and airflow. A chemical solvent is then aerosolized and constantly recirculated inside the chamber to ensure consistent coverage on even complex internal geometry. Any remaining solvent is then evaporated while the machine simultaneously cures what has condensed onto part geometry. This entire process spans only one-to-two hours depending on the loaded material, and after this time parts will have a much-improved surface finish.

Parts vapor smoothed by an AMT system exhibit surface finish comparable to an injection molded equivalent.

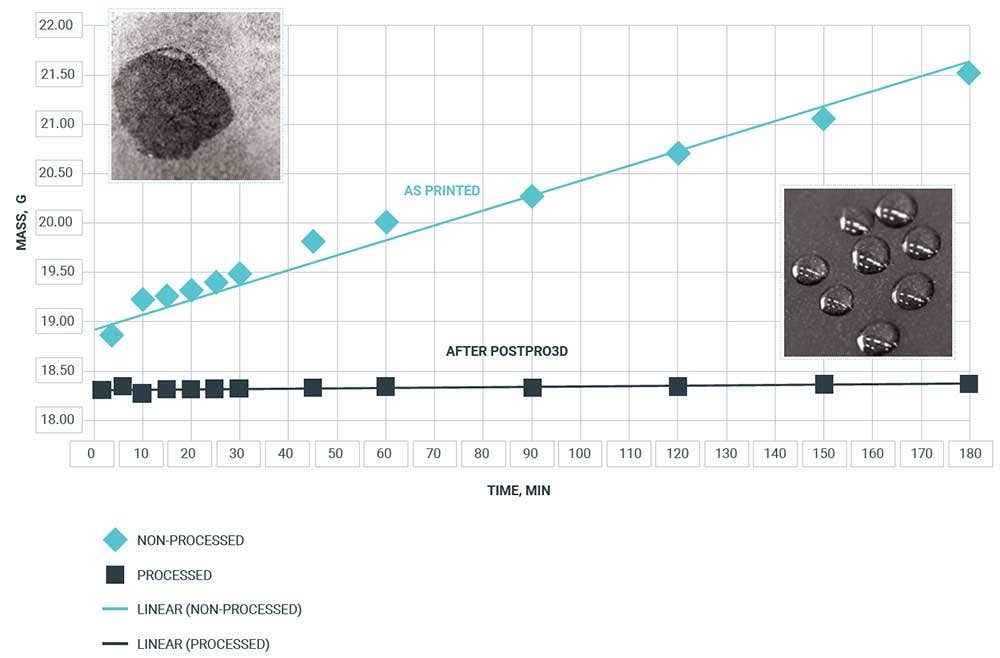

Additional part properties beyond surface finish are also enhanced by the AMT vapor smoothing process. Parts have been shown to retain their ultimate tensile strength while also seeing an increased elongation at break after being smoothed. AMT smoothed parts are also shown to be less resistant to bacterial growth and are sealed against both liquid and gases. This latter improvement is extremely useful in the world of 3D printing where many materials are hygroscopic or otherwise not resistant to liquids.

The AMT chemical vapor can completely seal 3D-printed parts against liquids.

PostPro Pure retains the same capabilities as prior AMT solutions while being fully plant-based. The solution is also food-grade, biodegradable, and FDA-approved upon launch. Additionally, PostPro Pure can vapor smooth the same elastomers, composites, and rigid plastics that existing AMT consumables can. This makes AMT a great solution for companies looking to become more sustainable through additive manufacturing.

Parts that are processed with AMT are smoother, stronger, and much more vibrant.

Thanks for reading everyone! We are excited about this new post-processing option and the ability to become more sustainable while continuing to improve 3D printed parts. PostPro Pure can be used on both the SF50 and the SF100 and existing machines can make use of this sustainable chemistry through an optional paid upgrade. Check out our site for more information on AMT Post-Processing Systems, and if you have any questions be sure to contact us at Hawk Ridge Systems today!