In 2016, Markforged launched its first Industrial-level 3D printer known as the Mark X. The Mark X would eventually be rebranded as the X7 and featured a large format build volume, a laser micrometer that could be used for in-process inspection, and the ability to print parts more accurately than any Markforged system before it.

Since its launch, customers around the globe have used the X7 to print functional parts, such as a CE-certified lifting tool that can support up to 2,100 lbs., in-house replacements for large format cutting tools and parts for wind turbine blades.

Now, Markforged is excited to announce its next generation of industrial-level printers — the FX10 3D printers.

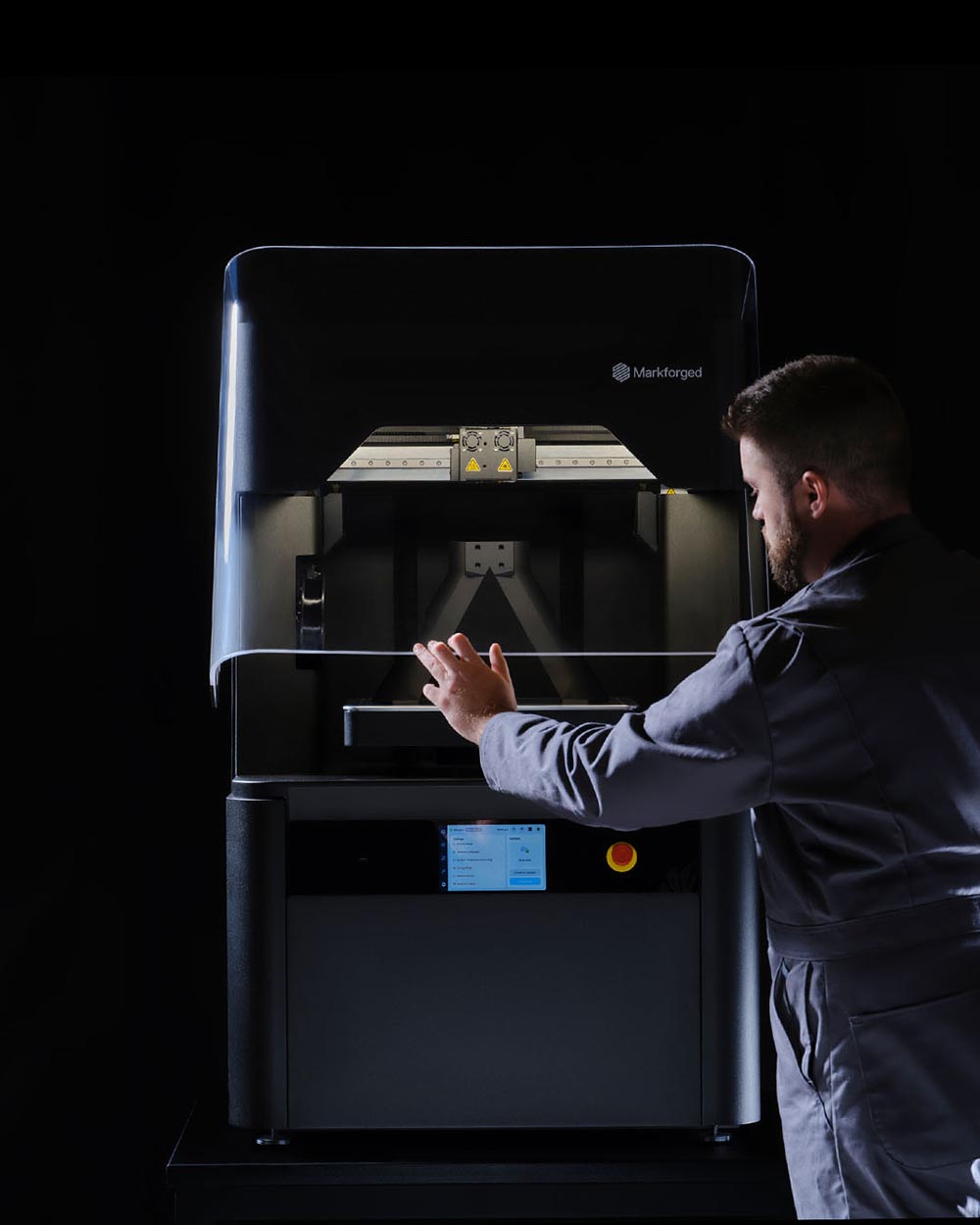

The FX10 is the latest printer in the Markforged Industrial line — built to print large, accurate, functional parts.

The FX10 is the latest printer in the Markforged Industrial line — built to print large, accurate, functional parts.

New Printer on the Block

From Day 1, Markforged designed the FX10 to be a machine that iterated and improved on what made the X7 such a capable turnkey solution.

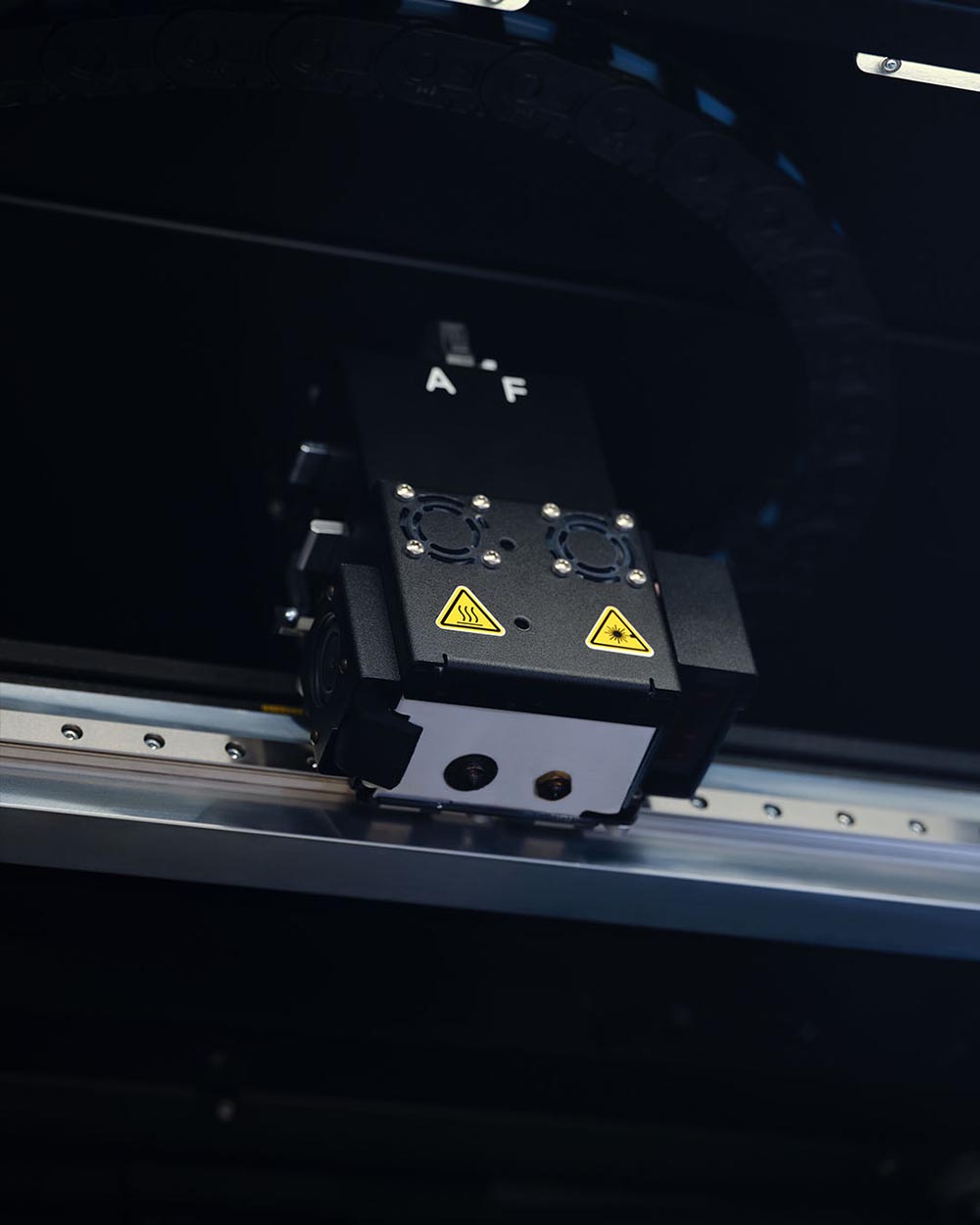

Like its older cousin, the FX10 can reinforce printed parts with continuous strands of carbon fiber, resulting in composite geometries that can even replace metal equivalents. The FX10 also inherits the built-in laser micrometer that confirms the print bed is level before each print, though the FX10 takes this capability a step further and will automatically level the print bed as needed.

Just like other printers from Markforged, the FX10 will also be built on top of the Eiger print prep software, allowing operators to upload their designs and get them ready for printing in minutes.

A close-up of the FX10 print head featuring a laser micrometer that can verify a level print bed and scan parts while printing.

More Automation, More Parts — What Sets the FX10 Apart

While there are certainly some similarities to previous machines in the Markforged industrial 3D printer lineup, the FX10 aims to set itself apart by implementing many features previously requested by Markforged customers.

Two of the most common feature requests — increased print volume and faster print speeds — are immediately apparent when taking a high-level look at the FX10.

LARGER BUILD VOLUME

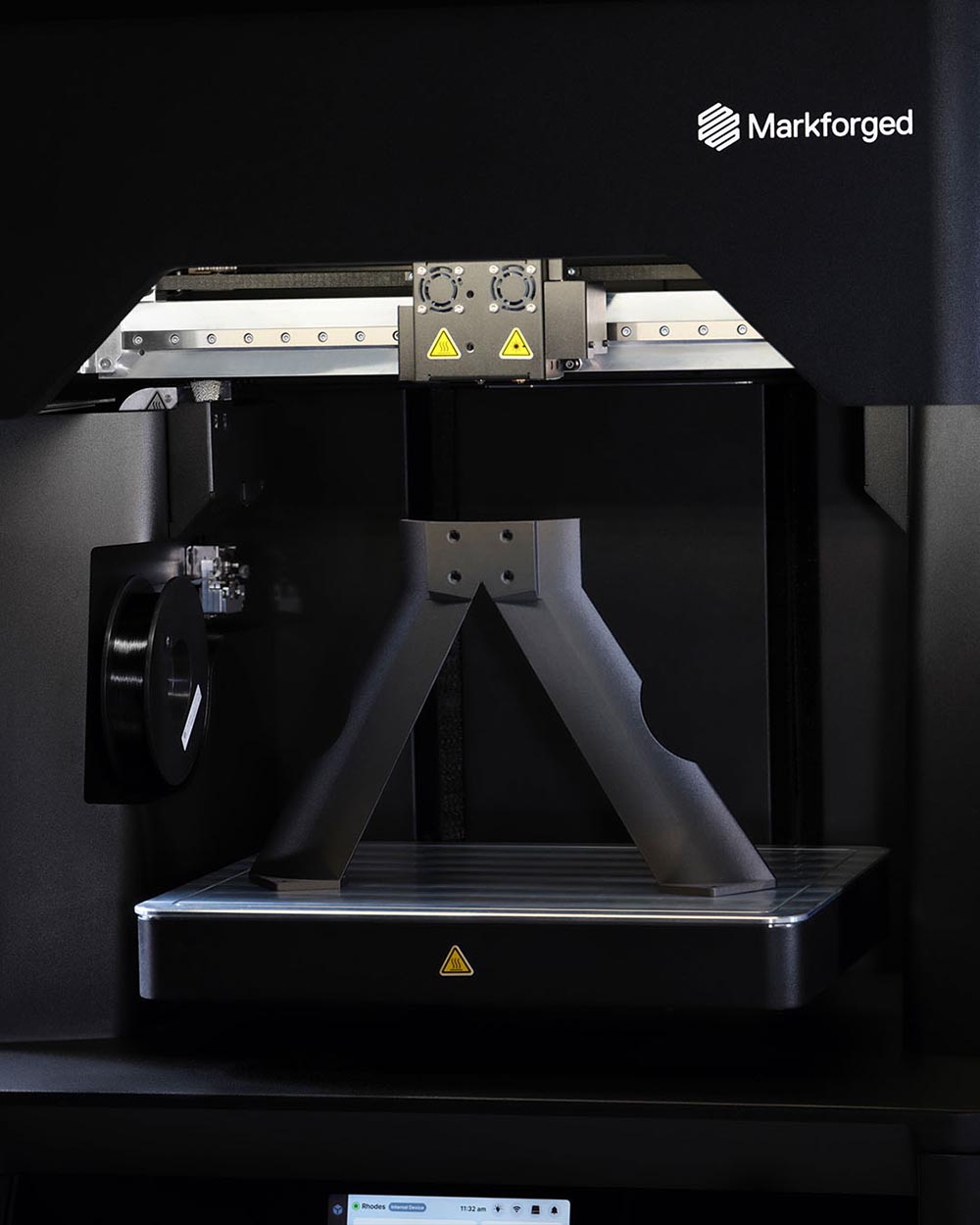

The build envelope on the FX10 reaches 375mm x 300mm x 300mm, which is nearly double the volume compared to the X7. This increased print area allows for more parts in a build or larger parts in general, reducing the need to spread parts across multiple builds.

The FX10 features a large build volume of 375mm x 300mm x 300mm — perfect for large parts or a build containing many parts.

Of course, a larger print volume does not always lend itself to increased productivity if the machine itself cannot print faster than one with a smaller footprint.

HEATED BUILD CHAMBER & AUTOMATIC MATERIAL CHANGEOVER

Markforged has included two key features to help the FX10 print faster, with those being a heated build chamber and automatic material changeover.

The chamber itself can reach up to 60C, which allows the FX10 to reach print speeds up to twice as fast as the X7 Turbo Print mode. The heated chamber allows Onyx to be more stable when printed at faster speeds, so users can get parts in hand quicker and reduce their own turnaround times.

Faster print speeds mean faster time-to-part, which can be critical during the product development cycle.

FOUR MATERIAL BAYS

The FX10 also features four storage bays dedicated to the primary plastic material being used, which can each store 800cc spools of material.

These material bays are humidity-controlled and feature automatic material changeover, largely removing the need for manual operator intervention when a spool of material runs out mid-print.

The FX10 has four dedicated, humidity-controlled material bays. These will automatically use the next spool when one runs out, meaning that the printer will work for longer periods of time – even when the operator is not.

AUTOMATIC BED LEVELING

The ability to print for longer consecutive intervals is not the only operator-related improvement Markforged brings to the FX10.

Automatic bed leveling and pre-print calibration remove a key task that has previously needed to be performed manually. The print bed itself is designed to vacuumseal a print sheet on top of it, which makes parts with a large amount of contact against the build plate quicker and easier to remove.

Many of the components in the FX10 — including the print head — are also designed to be modular and easily swappable when future upgrades to the machine are released.

The print bed is a precision-machined component that features a vacuum channel for print sheets and grooves that work in conjunction with the print head to automate the leveling process.

REQUIRES POWER FROM ONE STANDARD OUTLET

Last but certainly not least, the FX10 only requires power from a standard outlet. Because the system does not need a dedicated power drop, it can be placed and operated in locations that may otherwise not be possible due to facility requirements.

The Final Note

We are excited to see what our customers print once they can get their hands on this latest 3D printer from Markforged. More information and coverage on the FX10 are coming in the next few weeks, so stay tuned for updates on the system and its availability.

If you have any questions about what the FX10 can do or would like to talk to one of our experts about a potential application, contact us today.